Preparation method of loudspeaker diaphragm based on graphene and polyetherimide

A polyetherimide and graphene technology, applied in sensors, electrical components, etc., can solve the problems of diaphragm strength, electroacoustic efficiency and difficult frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

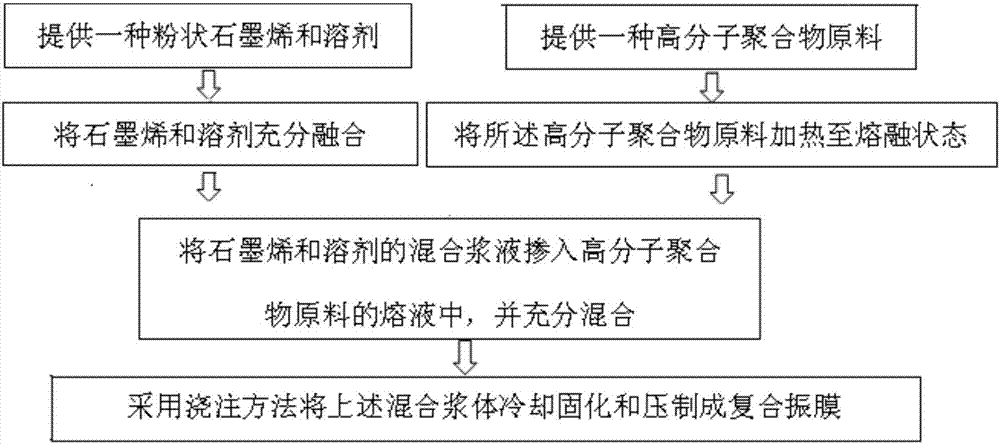

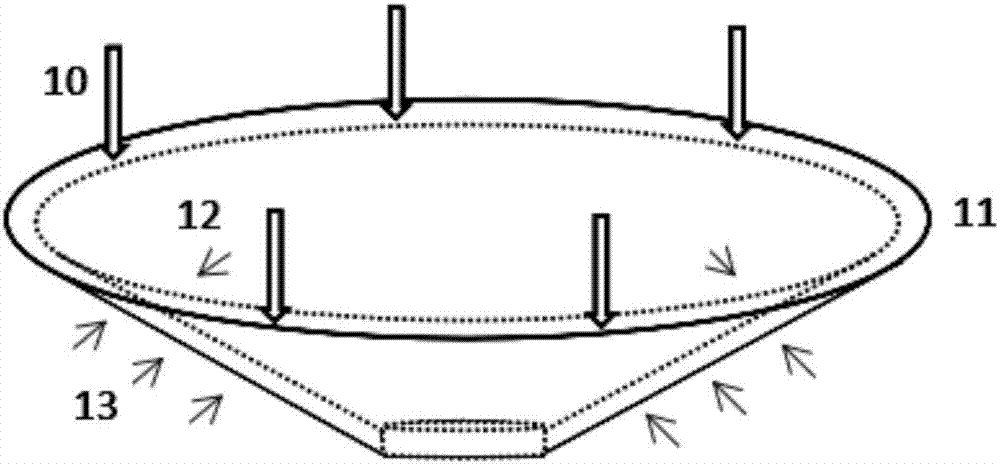

[0021] Such as figure 1 and figure 2 Shown, the preparation method of the loudspeaker diaphragm based on graphene and polyetherimide (PEI) of embodiment 1 comprises the steps:

[0022] (1) Disperse the graphene material in ethylene glycol to form a mixed solution of graphene and ethylene glycol; melt the polymer polyetherimide into a PEI solution at a high temperature of 340°C to 415°C;

[0023] (2) Add the mixed solution of graphene and ethylene glycol into the PEI solution and stir and mix thoroughly. The ethylene glycol decomposes and volatilizes under the condition of 340°C to 415°C, and the high molecular polymer polyetherimide (PEI) is mixed with Miscellaneous graphene material, finally form PEI-graphene material mixed slurry, the content of PEI material in the mixed slurry is 65%, the content of graphene material is 35%.

[0024] (3) The PEI-graphene material mixed slurry is cooled and solidified and pressed into a composite diaphragm by pouring method, that is, the ...

Embodiment 2

[0026] Such as figure 1 Shown, the preparation method of the loudspeaker diaphragm based on graphene and polyetherimide (PEI) of embodiment 2 comprises the steps:

[0027] (1) Disperse the graphene material in ethylene glycol to form a mixed solution of graphene and ethylene glycol; melt the solid carbon fiber reinforced PEI material at 340°C to 415°C to form a PEI solution;

[0028] (2) Add the mixed solution of graphene and ethylene glycol into the PEI solution and stir and mix thoroughly. The ethylene glycol decomposes and volatilizes under the condition of 340°C to 415°C. The carbon fiber-reinforced PEI material is used as the base material to dope the graphene material, and finally formed PEI-graphene material mixed slurry, the content of PEI material in the mixed slurry is 85%, and the content of graphene material is 15%.

[0029] (3) Cool and solidify the PEI-graphene material mixed slurry and press it into a composite diaphragm by pouring method, specifically: inject ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com