Honey and tartary buckwheat tea and preparation method thereof

A technology of tartary buckwheat tea and honey, which is applied in the field of health drinks, can solve the problems that honey and tartary buckwheat cannot be brewed at the same time, increase the solubility of tartary buckwheat, achieve good hygroscopic effect, improve the appearance quality of products, and solve the problem of excessive hygroscopicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

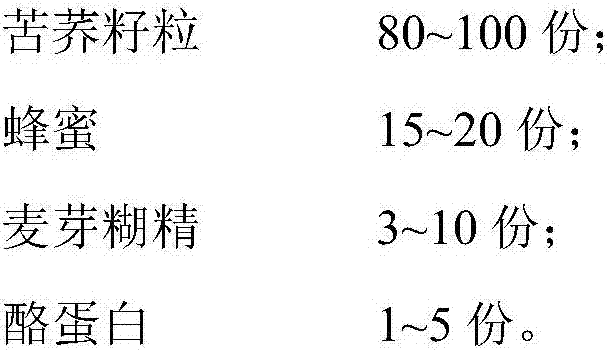

[0054] A preparation method of honey tartary buckwheat tea, in parts by weight, the added raw material components are as follows:

[0055]

[0056] The preparation method comprises the following steps:

[0057] A. Raw material pretreatment

[0058] Selected, disease-free, plump tartary buckwheat grains of the same year, washed with clean water to remove some impurities, dried in a dryer, dried at 60°C for 3 hours, and dried at 40°C for 5 hours, and the final moisture content of tartary buckwheat grains was controlled below 20%; after drying The grains are pulverized, all passed through a 40-mesh sieve and sealed for future use, so as to obtain tartary buckwheat grain powder;

[0059] B. Granulation

[0060] Mix tartary buckwheat powder with production water, mix evenly with the stirring rotor, set the rotating speed at 50r / min, control the water temperature at 40°C, shape the tartary buckwheat mixture through a granulator, and the finished granules are in a cylindrical shap...

Embodiment 2

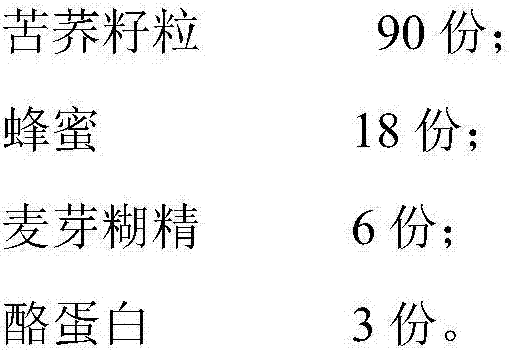

[0075] A preparation method of honey tartary buckwheat tea, in parts by weight, the added raw material components are as follows:

[0076]

[0077] The preparation method comprises the following steps:

[0078] A. Raw material pretreatment

[0079] Selected, disease-free, plump tartary buckwheat grains of the same year, washed with clean water to remove some impurities, dried in a dryer, dried at 65°C for 5 hours, and dried at 45°C for 6 hours, and the final moisture content of tartary buckwheat grains was controlled below 20%; after drying The grains are pulverized, all passed through a 40-mesh sieve and sealed for future use, so as to obtain tartary buckwheat grain powder;

[0080] B. Granulation

[0081] Mix tartary buckwheat powder with production water, use the stirring rotor to mix evenly, set the rotation speed at 70r / min, control the water temperature at 45°C, shape the tartary buckwheat mixture through a granulator, water acts as a bridge between particles, and u...

Embodiment 3

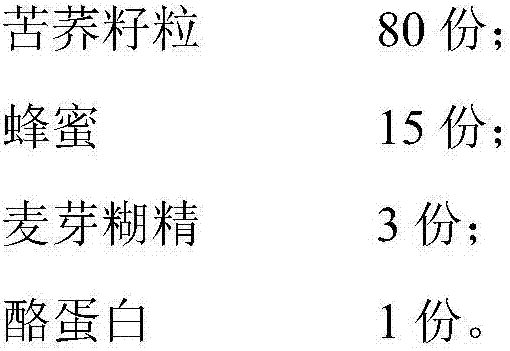

[0097] A preparation method of honey tartary buckwheat tea, in parts by weight, the added raw material components are as follows:

[0098]

[0099] The preparation method comprises the following steps:

[0100] A. Raw material pretreatment

[0101] Select the full-fledged tartary buckwheat grains of the same year, wash them with clean water to remove some impurities, and dry them in a tunnel dryer. Dry at 63°C for 4 hours and at 43°C for 6 hours. The final moisture content of the tartary buckwheat grains is controlled below 20%. After drying, the grains are pulverized, all of which are passed through a 40-mesh sieve and sealed for future use, so as to obtain tartary buckwheat grain powder;

[0102] B. Granulation

[0103] Mix tartary buckwheat powder with production water, use the stirring rotor to mix evenly, set the rotation speed at 60r / min, control the water temperature at 43°C, shape the tartary buckwheat mixture through a granulator, water acts as a bridge between p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com