Die-casting die and die-casting device

A die-casting mold and mold technology, applied in the field of die-casting molds and die-casting equipment, can solve the problems of uneven temperature distribution of slider core pulling, difficulty in workshop production, cracking of mold structure, etc., and it is easy to stabilize the production state and improve the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

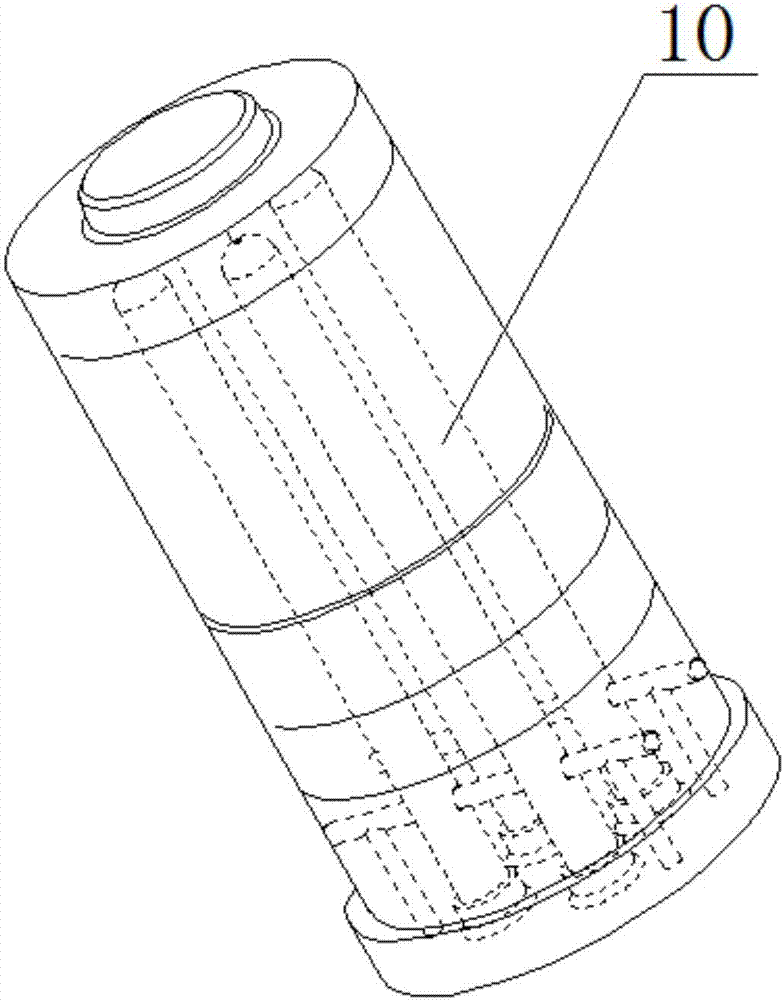

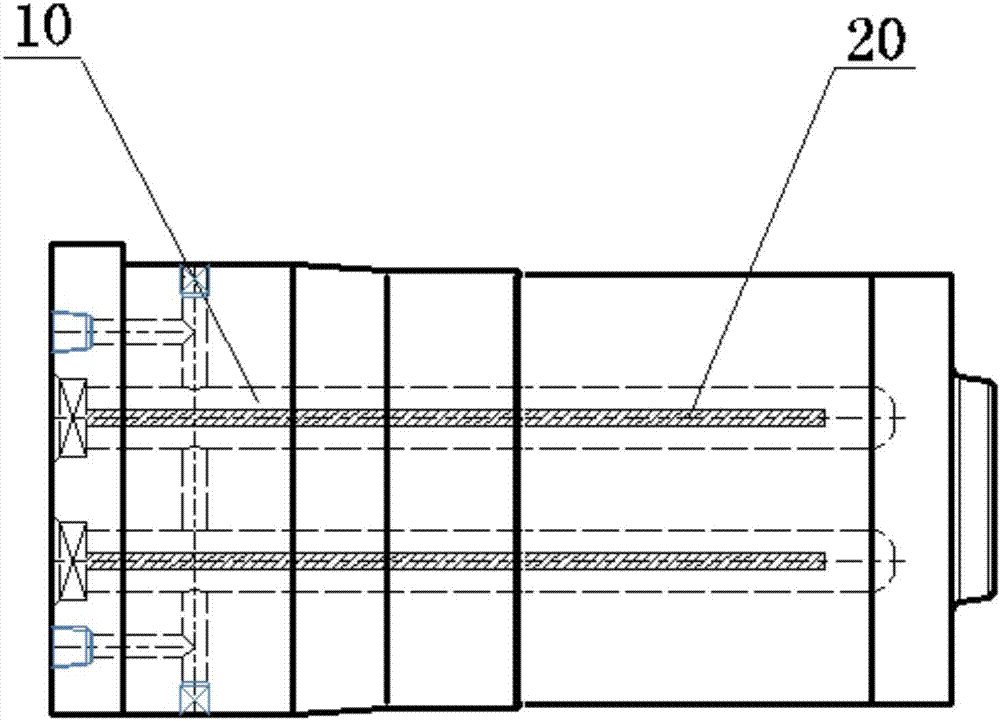

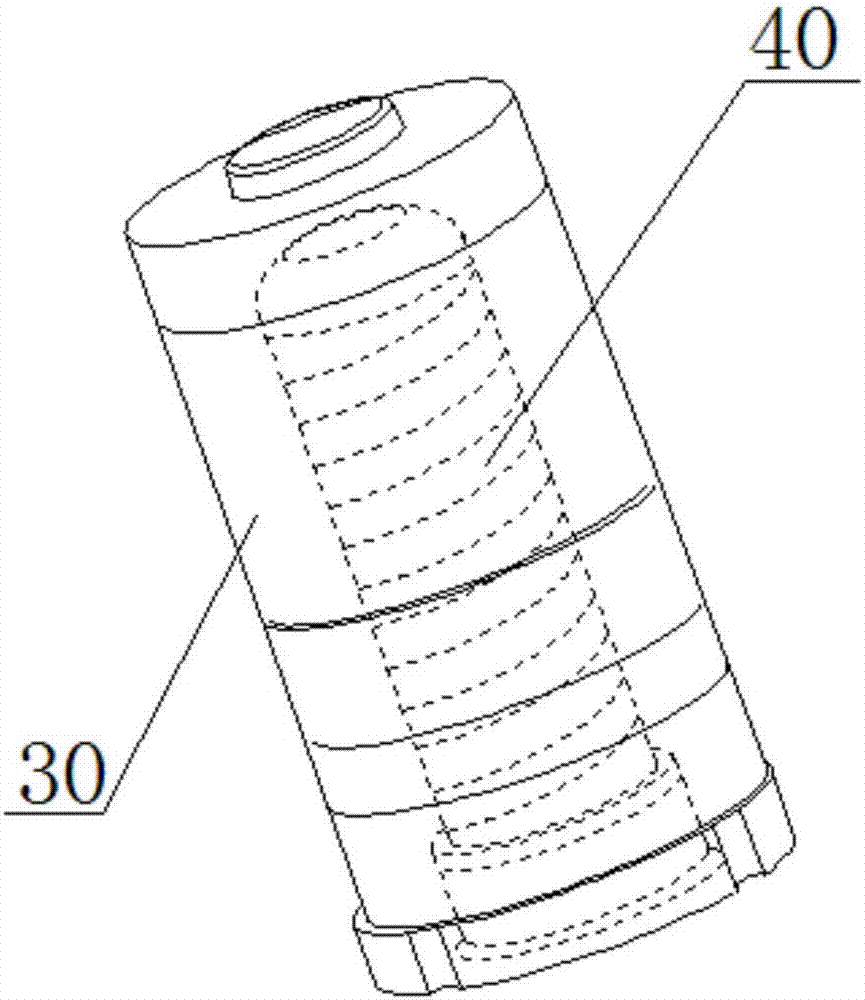

[0029] Such as figure 1 - Figure 6As shown, the die-casting mold provided by the present invention includes a mold core 30 and a cooling water circuit insert 40; the outer surface of the cooling water circuit insert 40 is provided with a helical structure, and the helical structure includes a spirally arranged groove; the The central position of the mold core 30 is provided with a blind hole 300, the blind hole 300 is used to install the cooling waterway insert 40, the inner wall of the blind hole 300 and the groove provided on the outer surface of the cooling waterway insert 40 form a spiral pipe 400; one end of the cooling water circuit insert 40 is provided with a water inlet 410 and a water outlet 420, and the water inlet 410 and the water outlet 420 communicate with the spiral pipe 400 to form a cooling water circulation loop. On the one hand, using the die-casting mold provided by the present invention can make the cooling water take away heat evenly from the mold core...

Embodiment 2

[0035] The die-casting mold provided by the present invention includes a mold core 30 and a cooling water circuit insert 40; a spiral structure is provided on the outer surface of the cooling water circuit insert 40, and the spiral structure includes a spirally arranged groove; the mold mold The central position of the core 30 is provided with a blind hole 300, the blind hole 300 is used to install the cooling water circuit insert 40, the inner wall of the blind hole 300 and the groove provided on the outer surface of the cooling water circuit insert 40 form a spiral pipe 400; One end of the cooling water circuit insert 40 is provided with a water inlet 410 and a water outlet 420, and the water inlet 410 and the water outlet 420 communicate with the spiral pipe 400 to form a cooling water circulation loop. On the one hand, using the die-casting mold provided by the present invention can make the cooling water take away heat evenly from the mold core 30, and form a uniform tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com