Adjustable pan punch

A punching machine and adjustable technology, applied in the field of punching machines, can solve the problems of time-consuming and laborious, low efficiency, narrow application range, etc., and achieve the effect of simple overall structure and easy fixture position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and example.

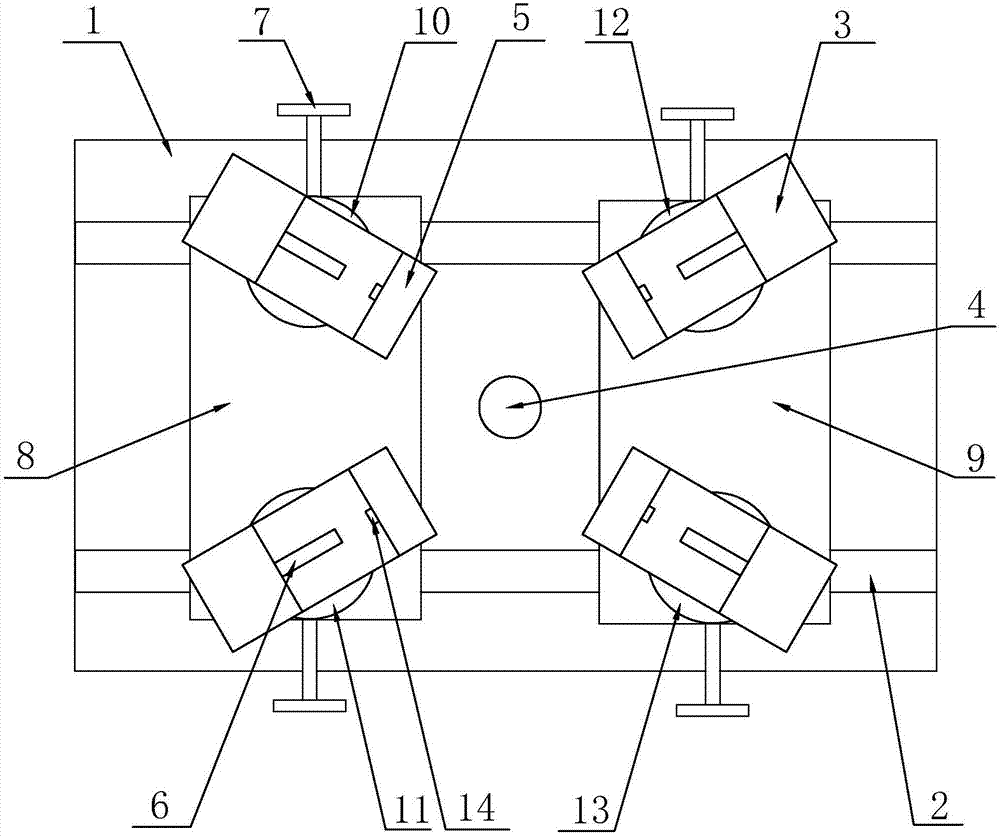

[0017] Such as figure 1 As shown, the present invention provides an adjustable pot punching machine, which includes a machine platform 1, a guide rail 2 is laid on the machine platform 1, a support platform that can move along the guide rail 2 is mounted on the guide rail 2, and a turntable is provided on the support platform. , a clamp 3 for fixing the pot body is installed on the turntable, a positioning column 4 for placing the pot body upside down is erected at the center of the machine table 1, and a limiting block 5 for resisting the inner wall of the pot body and for The perforating drill bit 6 of pot body punching. The overall structure is simple, and the position of the clamp 3 is easy to adjust, which is suitable for quickly punching holes of different types of pot bodies.

[0018] In this embodiment, in order to enable the clamp 3 to move horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com