Multifunctional cutting pliers

A kind of wire pliers and multi-functional technology, applied in the field of tools for maintenance of electric equipment tools, can solve the problems of inability to peel off the insulation layer of electric wires, damage to nuts, inconvenient replacement, etc., to increase practicability, effectively clamp, ensure safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

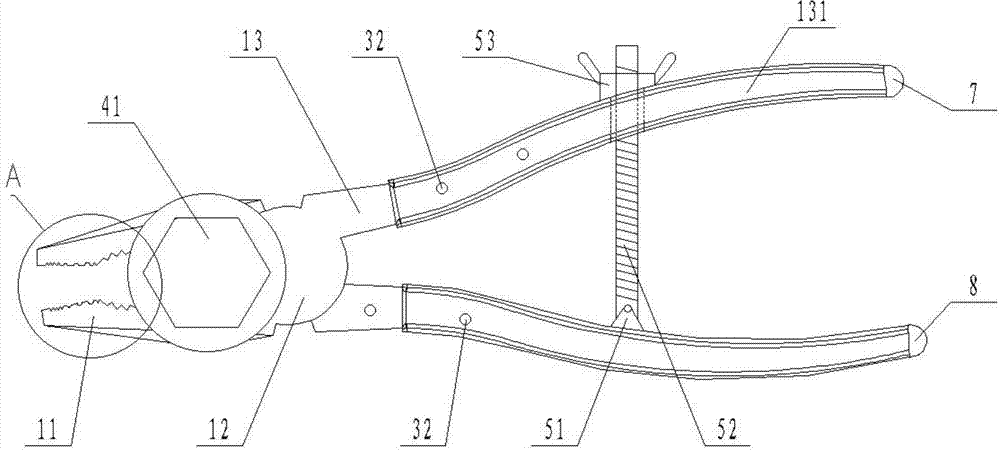

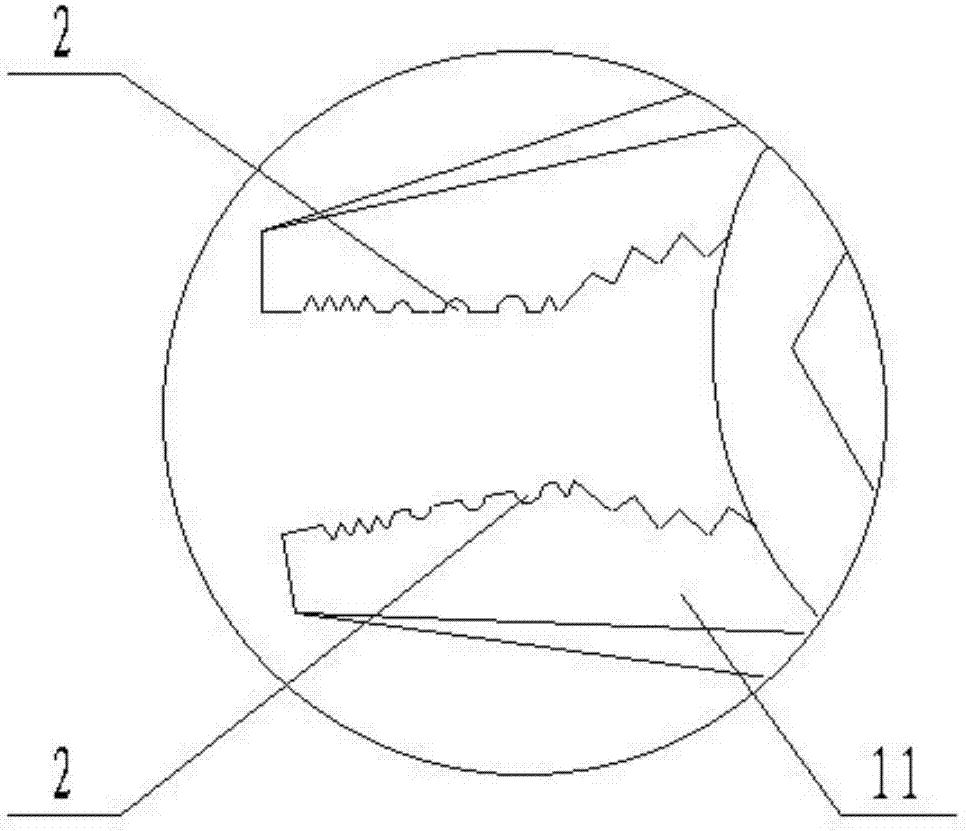

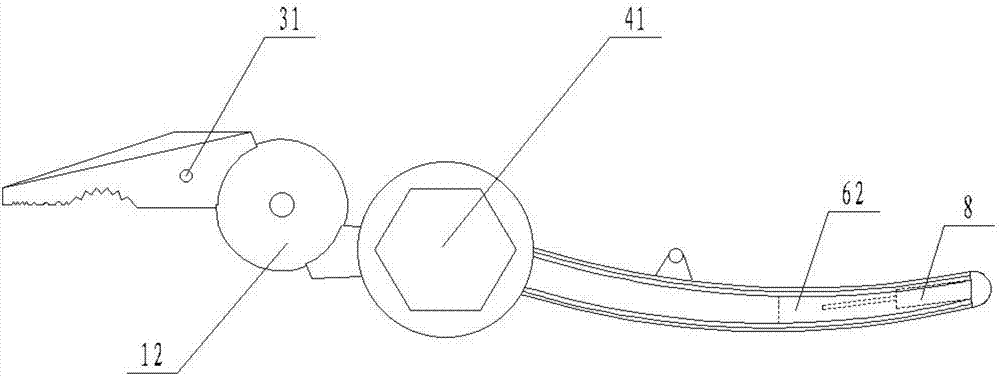

[0024] as attached figure 1 to attach Figure 5 As shown, it includes two oppositely arranged pliers bodies, stripping holes 2, nut fastening devices, clamping devices and auxiliary pliers handles 7, and each pliers body is successively pliers mouth 11, pliers gills 12 and pliers gills from left to right. The pliers handle 13, the two pliers bodies are hingedly connected at the pliers gills 12, several wire stripping holes 2 are sequentially arranged at the joints of the two pliers mouths 11, and the position near the edge is a blade, and the diameter of the circumference formed by the blade is the same as that of the inside of the wire. The diameters of the guide wires are equal. When you need to connect the wires, you only need to put the wires in the corresponding stripping holes 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com