Novel V-groove cutting machine

A cutting machine, a new type of technology, applied in metal processing and other directions, can solve problems such as cutter deformation, achieve the effects of avoiding deformation, fast and effective board processing, and preventing line of sight blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

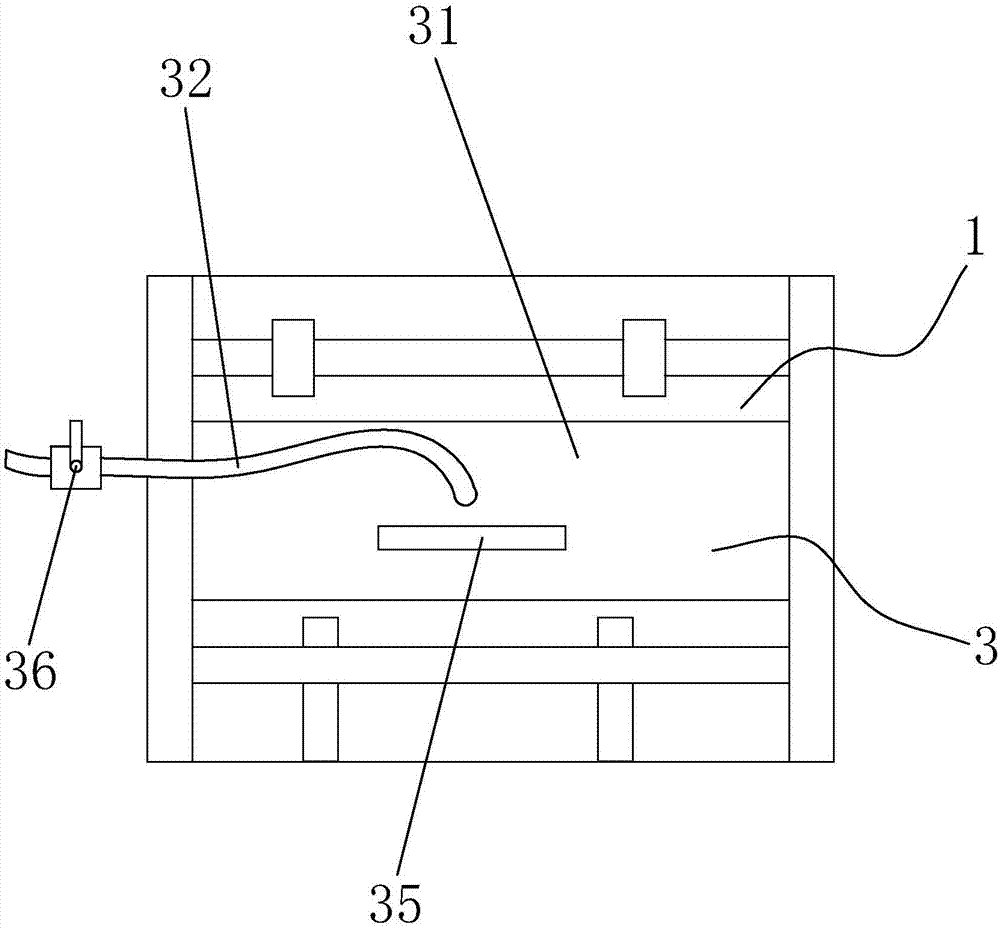

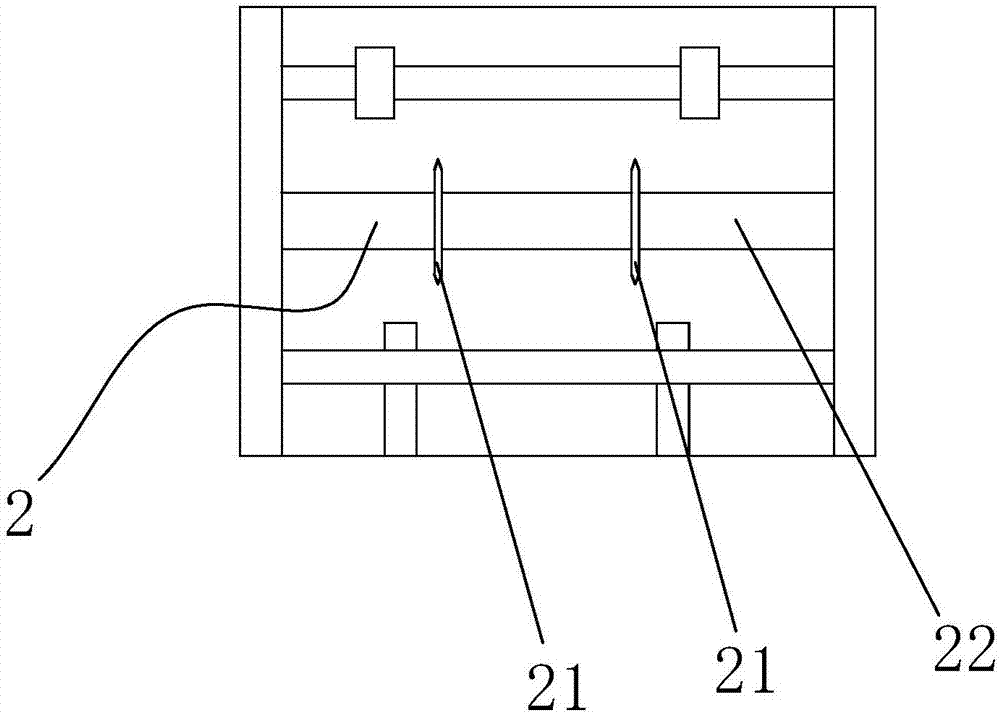

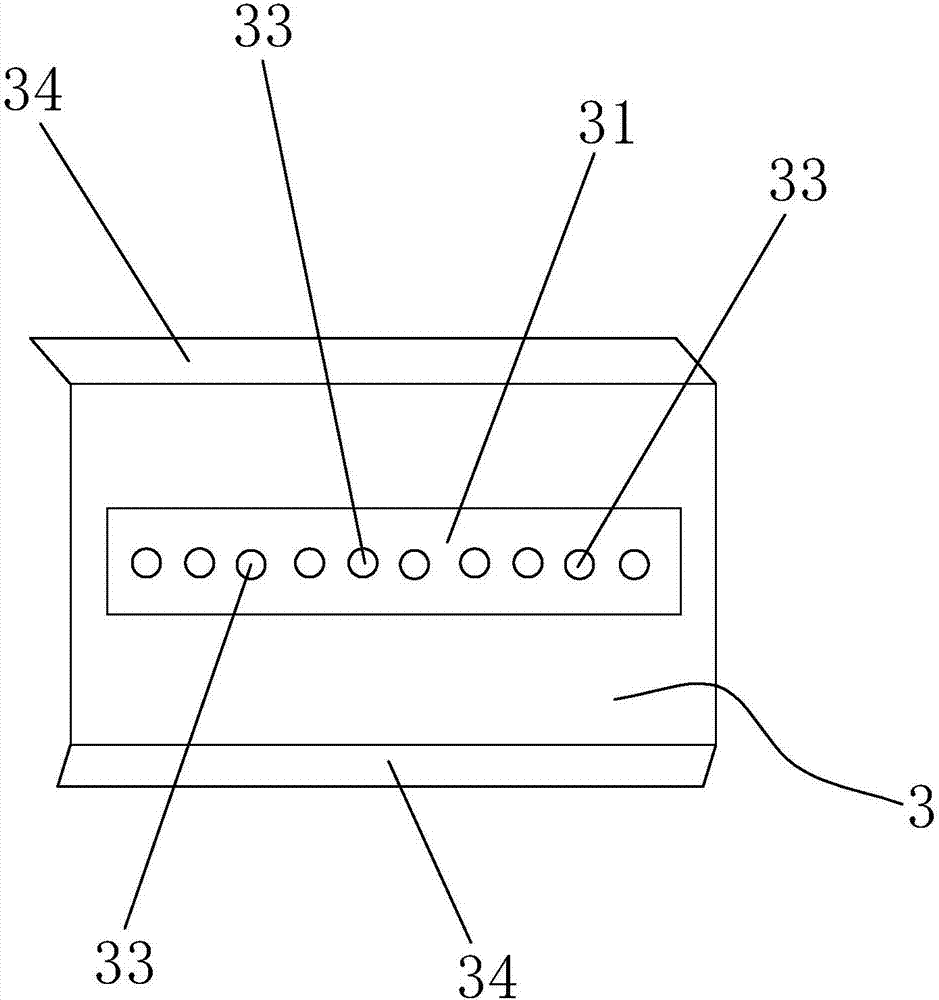

[0016] refer to Figure 1-Figure 3 , a novel V-groove cutting machine of the present invention includes a cutting machine body 1, and the cutting machine body 1 includes a cutting device 2 for performing a V-groove cutting process on a circuit board by means of rotary cutting and a device for reducing the temperature of the cutting device 2. The cooling device 3, the cooling device 3 includes a water outlet box 31 arranged along the cutting device 2 and a water delivery pipe 32 for supplying water to the water outlet box 31, the bottom of the water outlet box 31 is provided with a water outlet hole 33, and the water outlet box 31 covers the cutting device 2 and the water outlet hole 33 is directly above the cutting device 2. Specifically, the cutting device 2 can perform accurate and effective V-groove cutting processing on the circuit board, so that the circuit board can be quickly and effectively divided into boards along the V-groove; the cooling device 3 can effectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com