Glass antifogging wet tissue and preparation method thereof

An anti-fog and wet wipe technology, applied in chemical instruments and methods, other chemical processes, detergent compounding agents, etc., can solve problems such as hidden dangers of safe driving, insignificant effects, and obstacles to driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

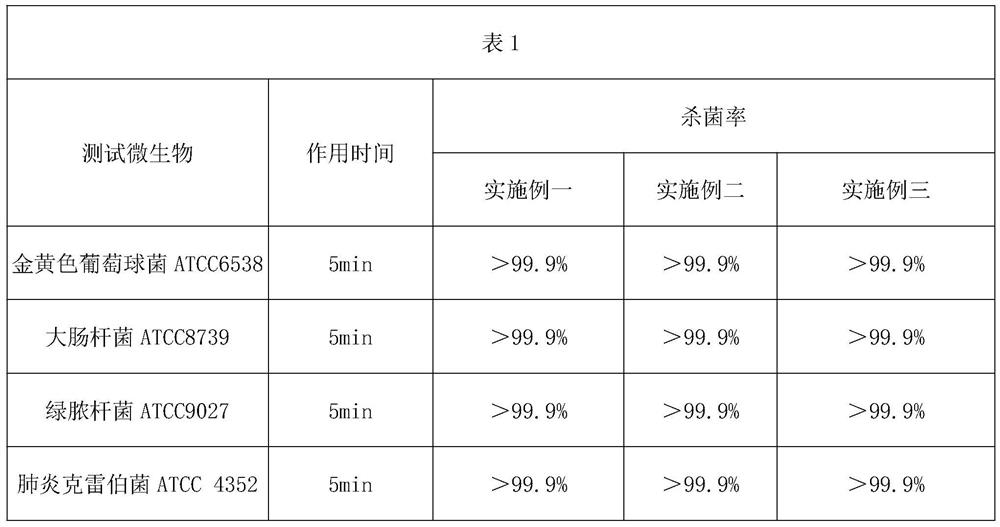

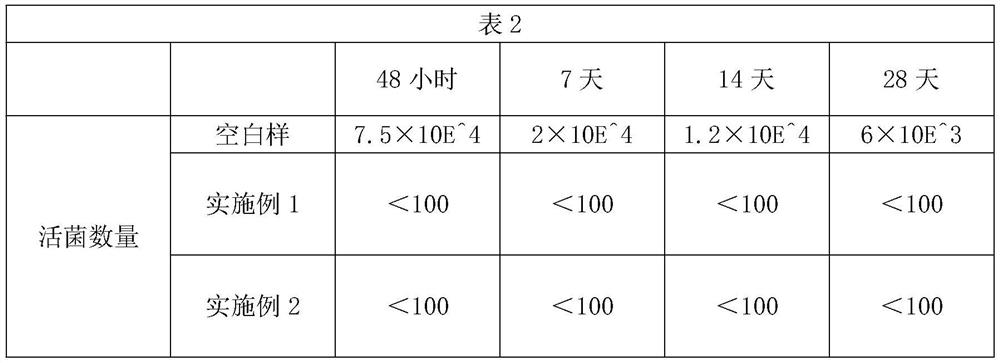

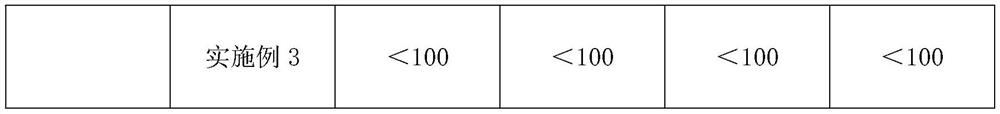

Examples

Embodiment 1

[0017] An anti-fog cleaning liquid, comprising the following substances in parts by weight: 0.05% of benzalkonium chloride, 0.5% of polyhexamethylene biguanide hydrochloride, 0.1% of hydrophilic surfactant, 15% of ethanol, iodo Butyl propynyl carbamate 0.01%, deionized water 63%.

[0018] The hydrophilic surfactant is an acrylic acid copolymer.

[0019] The second object of the present invention is to provide a method for preparing the anti-fog cleaning solution, comprising the following steps:

[0020] Step (1): Mix ethanol and butyl iodopropynyl carbamate according to a predetermined weight ratio at a temperature of 20°C and stir at a speed of 1500 rpm for 10 minutes to obtain the first mixed solution ;

[0021] Add polyhexamethylene biguanide hydrochloride, benzalkonium chloride and hydrophilic surfactant with a predetermined weight ratio into deionized water, stir at room temperature at a speed of 1000 rpm for 10 minutes until the material is uniform , to obtain the sec...

Embodiment 2

[0025] An anti-fog cleaning solution, comprising the following substances in parts by weight: 1.2% benzalkonium chloride, 0.9% polyhexamethylene biguanide hydrochloride, 0.5% hydrophilic surfactant, 22% ethanol, iodo 0.03% propynyl butyl carbamate, 76.6% deionized water.

[0026] The hydrophilic surfactant is an acrylic acid copolymer.

[0027] The second object of the present invention is to provide a method for preparing the anti-fog cleaning solution, comprising the following steps:

[0028] Step (1): Mix ethanol and butyl iodopropynyl carbamate according to a predetermined weight ratio at a temperature of 25°C and stir at a speed of 1800 rpm for 15 minutes to obtain the first mixed solution ;

[0029] Add polyhexamethylene biguanide hydrochloride, benzalkonium chloride and hydrophilic surfactant with a predetermined weight ratio into deionized water, stir at room temperature at a speed of 1200 rpm for 15 minutes until the material is uniform , to obtain the second mixed...

Embodiment 3

[0034] An anti-fog cleaning solution, comprising the following substances in parts by weight: 2.0% benzalkonium chloride, 1.5% polyhexamethylene biguanide hydrochloride, 2% hydrophilic surfactant, 32% ethanol, iodo 0.03% propynyl butyl carbamate, 80% deionized water.

[0035] The hydrophilic surfactant is an acrylic acid copolymer.

[0036] The second object of the present invention is to provide a method for preparing the anti-fog cleaning solution, comprising the following steps:

[0037] Step (1): Mix ethanol and butyl iodopropynyl carbamate according to a predetermined weight ratio at a temperature of 30°C and stir at a speed of 2000 rpm for 20 minutes to obtain the first mixed solution ;

[0038] Add polyhexamethylene biguanide hydrochloride, benzalkonium chloride and hydrophilic surfactant in a predetermined weight ratio into deionized water, stir at room temperature at a speed of 1500 rpm for 20 minutes until the material is uniform , to obtain the second mixed solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com