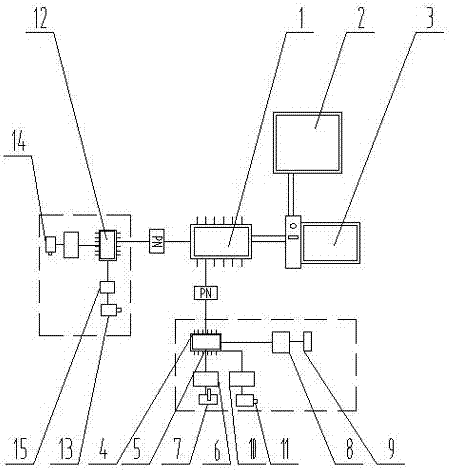

Corrugated paper board production line wet section control system

A corrugated cardboard and control system technology, applied in the direction of mechanical processing/deformation, can solve the problems of a large increase in defective cardboard products in the corrugated cardboard production line, reduce cardboard technology skills, avoid untimely and inaccurate, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

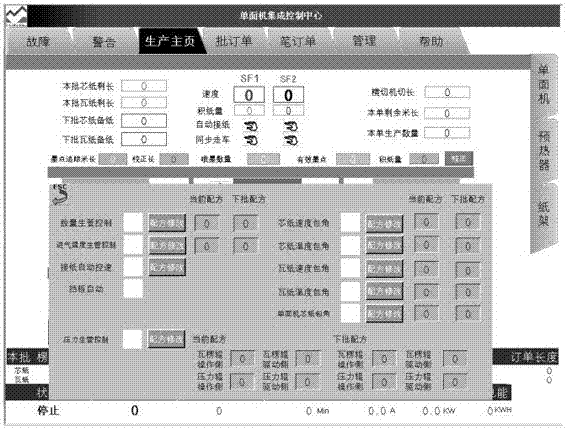

[0029] On the HMI production homepage of the man-machine interface, switch the production control mode of each machine to the production management control mode. After switching to this mode, the cardboard process parameters of all machines in the wet section integrated control center are read from the self-generated DCS industrial computer and automatically according to the process parameters. Adjustment.

[0030] On the batch order display page of the human-machine interface HMI, it shows that the currently produced cardboard order is the first batch. The core paper is 1880mm wide, the weight per square meter is 100 grams, the paper quality is 3-, and the required length is 15081 meters. The tile paper has a width of 1880mm, a weight of 100 grams per square meter, a paper quality of 8-, and a required length of 2337 meters. When the production of this order is completed, the splicer replaces the original paper and produces the second batch of orders. The core paper is 1780...

Embodiment 2

[0034] This implementation example is the calculation and control scheme of the remaining length of this batch of core paper in this system.

[0035] The remaining length of this batch of core paper is the core production data used to control the replacement of base paper, and it is also the accurate production length required by the customer's order. It uses the total length of the core paper required for this batch - (cutting length of the cross-cutting machine * number of knives) - the distance from the dryer to the cross-cutting machine - - the amount of accumulated paper in the flyover. Every time the cross-cutting machine cuts one knife, the remaining length of the core paper of this batch is updated once.

[0036]When the remaining length of this batch of core paper is 0, control the paper splicer to replace the core paper base paper. Refresh the process parameters of the new base paper board while replacing the base paper. At the same time, each machine PLC uses the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com