Soft acupuncture-resistant tubular fabric and manufacturing method thereof

A technology of tubular fabrics and manufacturing methods, applied in chemical instruments and methods, protective clothing, protective equipment, etc., can solve problems such as poor flexibility, restricted movement of the wearer, poor defense performance against sharp needle-like sharp objects, etc., to prevent Effects of damage, unlimited movement, and flexible wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: Soft anti-acupuncture arm guard and its manufacturing method

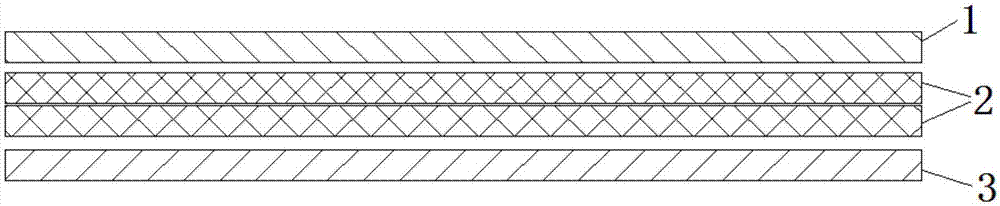

[0055] Such as figure 1 As shown, the soft anti-needle arm guard according to Embodiment 1 of the present invention includes a nylon cloth lining 1 and two layers of stainless steel braided layers 2 outside the nylon cloth inner lining 1, and the two layers of stainless steel braided layers 2 themselves The gaps do not overlap each other.

[0056] In order to enhance the protection of the arm guard, it also includes an ultra-high molecular weight polyethylene fiber layer 3 outside the outermost stainless steel braided layer 2 .

[0057] The manufacturing method of above-mentioned soft anti-needle arm guard comprises the following steps:

[0058] (1) Braid the inner nylon cloth lining on the arm guard mould, or sew the nylon cloth lining on the arm guard mould;

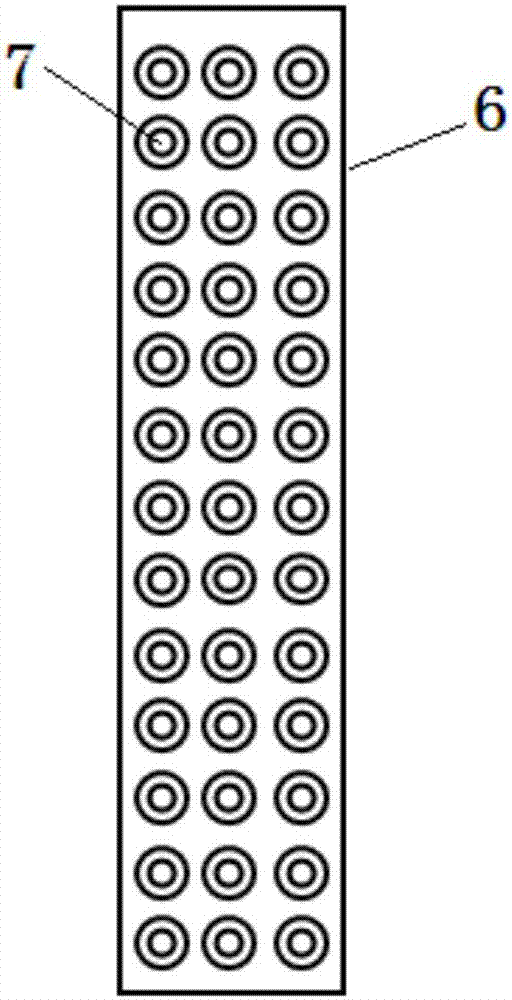

[0059] (2) Place the arm guard mold and the nylon cloth inner lining together on a 192-spindle knitting machine, use a stainless st...

Embodiment 2

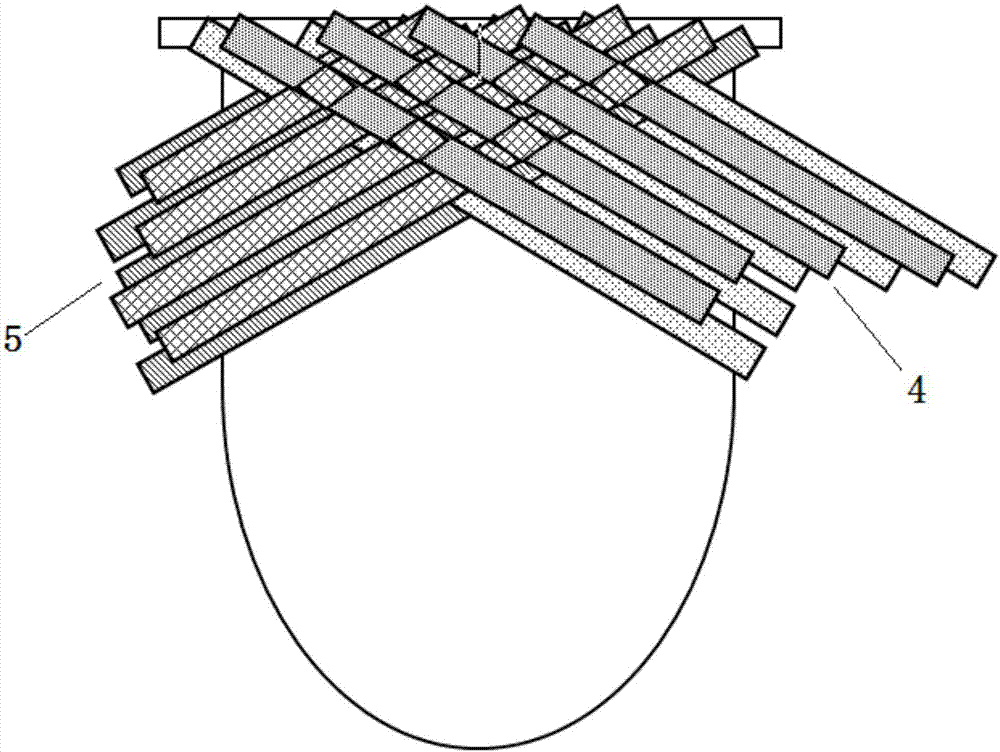

[0064] Embodiment 2: soft anti-needle glove and its manufacture method

[0065] The soft anti-needle glove described in Embodiment 2 of the present invention comprises a nylon cloth lining and two layers of stainless steel braided layers outside the nylon cloth inner lining, and the gaps between the two layers of stainless steel braided layers do not overlap each other; it also includes Layers of ultra-high molecular weight polyethylene fibers located over the outermost braided layer of stainless steel sheets.

[0066] The manufacture method of above-mentioned soft anti-needle gloves comprises the following steps:

[0067] (1) Weave the inner nylon lining on the glove mold, or sew the nylon lining on the arm mold;

[0068] (2) Place the glove mold and the nylon cloth lining together on a 192-spindle knitting machine, use a stainless steel sheet with a width of 2mm and a thickness of 0.05mm to weave a flexible tubular stainless steel braid layer, intersect the warp and weft at...

Embodiment 3

[0074] Embodiment 3: Soft anti-acupuncture arm guard and its manufacturing method

[0075] The soft anti-needle arm guard described in Embodiment 3 of the present invention includes a nylon cloth lining and a three-layer stainless steel braided layer outside the nylon cloth inner lining, and the gaps of the three stainless steel braided layers do not overlap each other; Consists of an ultra-high molecular weight polyethylene fiber layer over the outermost stainless steel sheet braid.

[0076] The manufacturing method of above-mentioned soft anti-needle arm guard comprises the following steps

[0077] (1) Braid the inner nylon cloth lining on the arm guard mould, or sew the nylon cloth lining on the arm guard mould;

[0078] (2) Place the arm guard mold and the nylon cloth inner lining together on a 192-spindle weaving machine and use a stainless steel sheet with a width of 2mm and a thickness of 0.05mm to weave the flexible tubular stainless steel sheet braiding layer, inters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com