Novel cable with explosive blast resistance

A new type of explosion shock technology, applied in the field of cables, can solve the problems of no cable body, anti-explosion protection, etc., and achieve the effect of attenuating shock waves and increasing the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

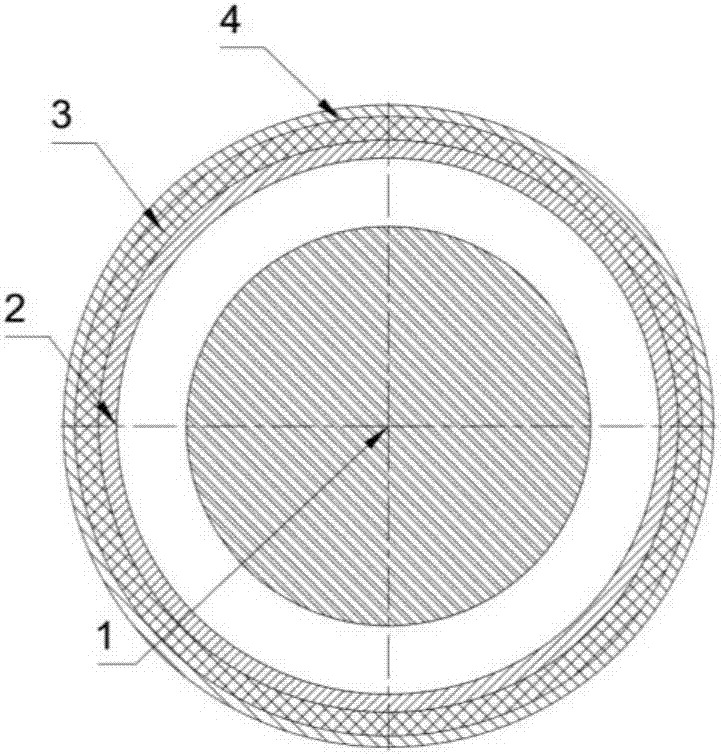

[0027] as attached figure 1 As shown, a novel anti-explosion shock cable, comprising a cable (1), a support tube (2) of a nested cable (1), is characterized in that the inner and outer walls of the support tube (2) are provided with anti-explosion Protective layer (3).

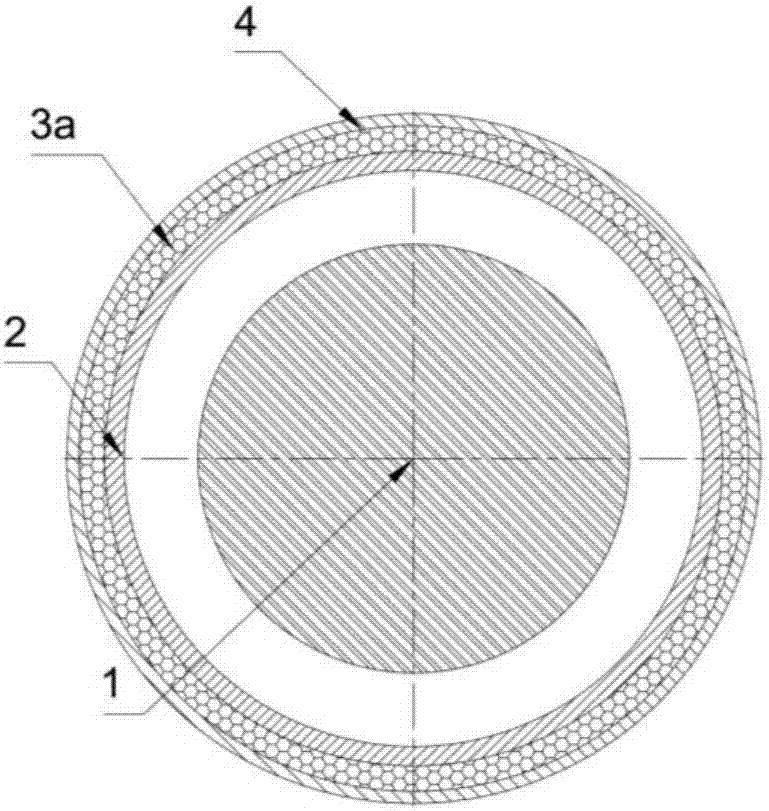

[0028] as attached figure 2 As shown, the support tube (2) is provided with an outer protection tube (4), and the gap between the support tube (2) and the outer protection tube (4) is filled with an anti-knock protection filling body (3a), and the anti-blast The protective filler (3a) is made of at least one of fiber reinforced concrete, active powder concrete, polyurea, polyurethane foam, aluminum foam, aluminum honeycomb or rubber. The outer protection tube (4) is nested outside the support tube (2), the anti-blast protection filling body (3a) is filled between the support tube (2) and the outer protection tube (4), and the cable (1) passing through the inside of the support pipe (2).

Embodiment 2

[0030] as attached figure 1 As shown, a novel anti-explosion shock cable, comprising a cable (1), a support tube (2) of a nested cable (1), is characterized in that the inner and outer walls of the support tube (2) are provided with anti-explosion Protective layer (3).

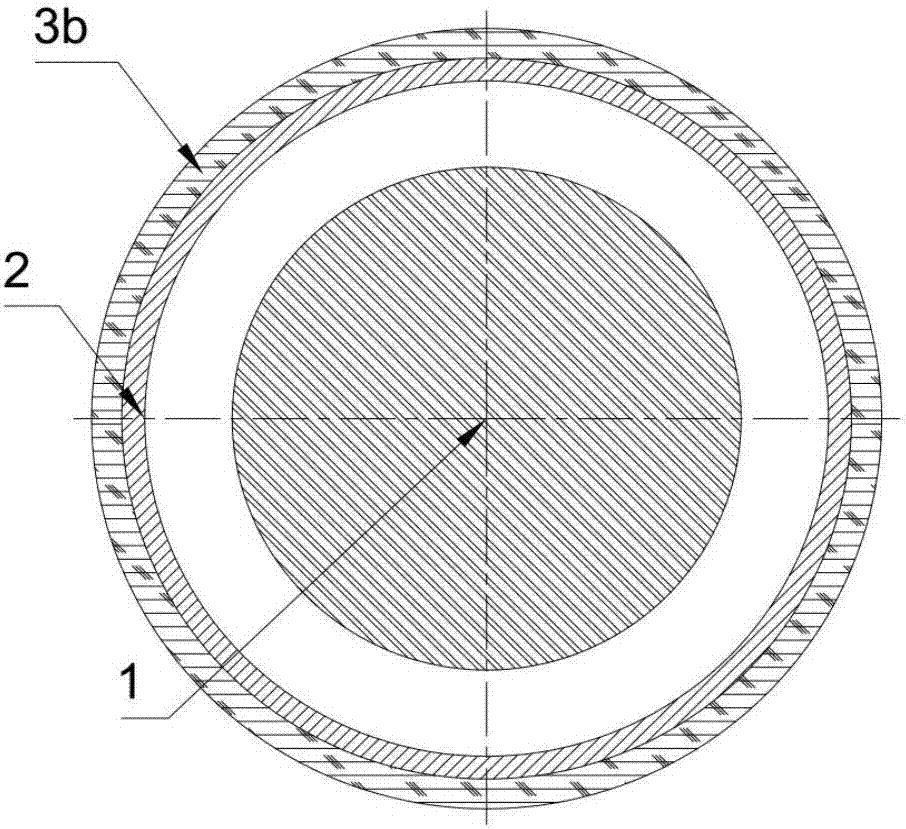

[0031] as attached image 3 , attached Figure 4 Shown, the anti-blast protective layer (3) of the inner and outer walls of the support pipe (2) is an anti-blast protective coating (3b), and the described anti-blast protective coating (3b) is a polyurea coating or a polyurethane coating. Made of at least one of . The outer wall of the support tube (2) is sprayed with an anti-knock protective coating (3b), and the cable (1) passes through the inside of the support tube (2); the inner wall of the support tube (2) is sprayed with an anti-knock protective coating layer (3b), the stay cable (1) passes through the inside of the support tube (2).

Embodiment 3

[0033] as attached figure 1 As shown, a novel anti-explosion shock cable, comprising a cable (1), a support tube (2) of a nested cable (1), is characterized in that the inner and outer walls of the support tube (2) are provided with anti-explosion Protective layer (3).

[0034] as attached Figure 5 As shown, the anti-blast protective layer (3) of the outer wall of the support tube (2) is an anti-blast protective cloth (3c), and the described anti-blast protective cloth (3c) is wrapped around the outside of the support tube (2). The protective cloth (3c) is made of at least one of fiber reinforced polymer, glass fiber cloth or carbon fiber cloth. The anti-blast protective cloth (3c) is wrapped around the outer surface of the support tube (2), and the stay cable (1) passes through the inside of the support tube (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com