Bottle cap shaping and drying machine

A dryer, integrated technology, applied in the direction of dryer, drying, local stirring dryer, etc., can solve problems such as affecting drying effect, affecting drying efficiency, and uneven drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

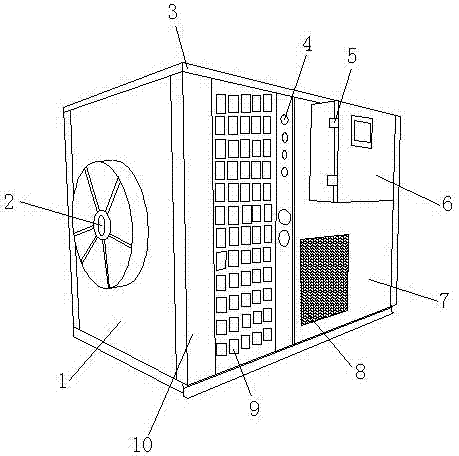

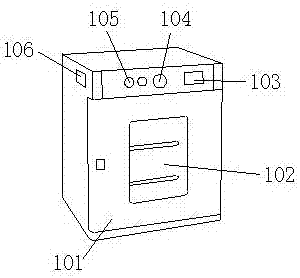

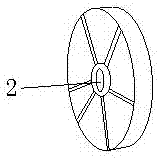

[0021] see Figure 1-Figure 3 , the present invention provides a technical solution: a flower shaping dryer, the structure of which includes a hot air box 1, a cooling fan 2, a partition 3, a power switch 4, a hinge 5, a control box 6, a sealing plate 7, and a smoke exhauster 8. Heat exchanger 9, sensing device 10, the air cooler 2 and the hot air box 1 are movably connected in an interference fit manner, the inside of the air cooler 2 is provided with blades, and the air cooler 2 passes through the hot air box 1 and The heat exchanger 9 is connected as a whole, the air cooler 2 is an annular structure, and the radius of the air cooler 2 is 10cm, the air cooler 2 is connected with the dividing plate 3 through the hot air box 1, and the dividing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com