Pipeline type material sampling device

A sampling device and pipeline-type technology, which is applied in the field of pipeline-type material sampling devices, can solve the problems of sampling result deviation, complicated operation, and injury to sampling personnel, and achieve the effect of small external force and simple sampling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

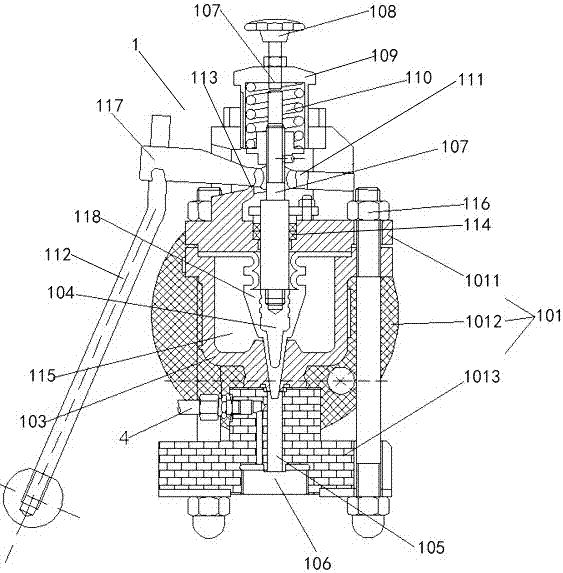

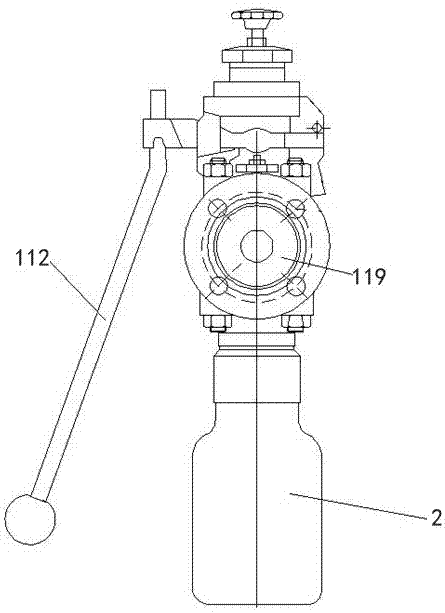

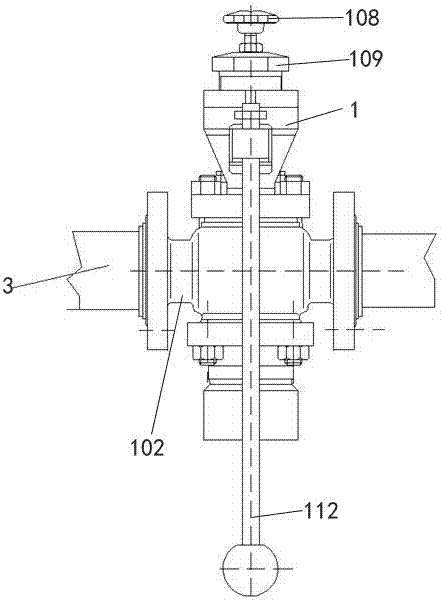

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0025] see Figure 1-4 .

[0026] The invention discloses a pipeline type material sampling device, which comprises a sampling short connection device 1 and a sampling bottle 2 connected with a material delivery pipe 3, the main body of the sampling short connection device 1 is a tank body 101 with a cavity 115 , the front and rear sides of the tank body 101 are provided with through openings 102 for communicating with the material delivery pipe 3, the tank body 101 communicates with the material delivery pipe 3 through a flange 119, and the inside of the tank body 101 is provided with a valve seat 103 With the matching valve core 104, the bottom of the valve seat 103 is provided with a sampling channel 105, and the bottom of the sampling channel 105 is provided with a sampling port 106 for communicating with a sampling bottle, and the sampling channel 105 is nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com