Multifunctional multi-field coupled seepage experiment device and testing method

An experimental device and multi-functional technology, which can be used in measurement devices, earth-moving drilling, permeability/surface area analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

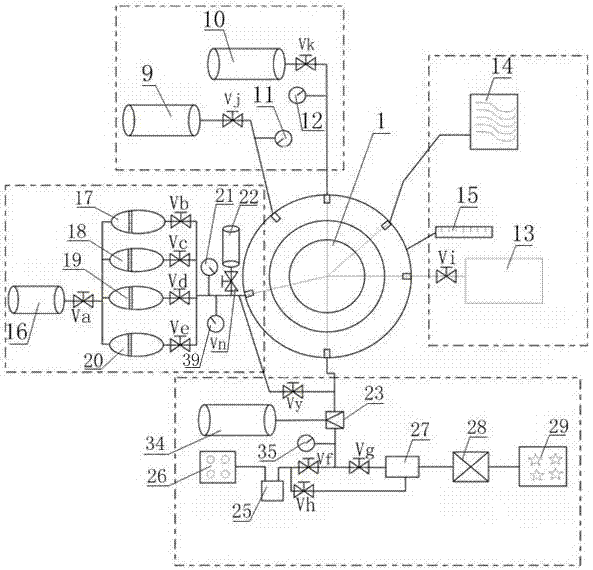

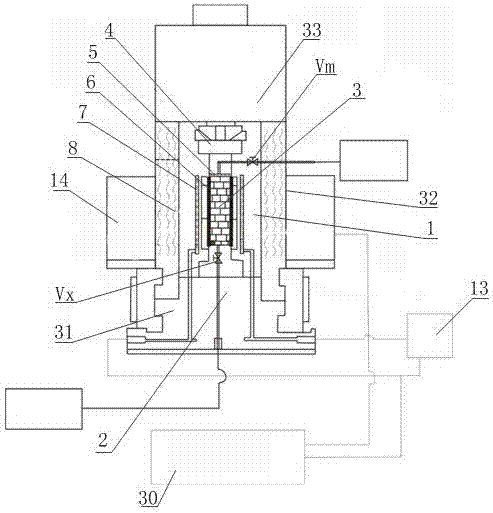

[0057] Such as Figure 1~2 As shown, a multi-field coupling seepage multifunctional experimental device, which includes a device body, a stress field control system, a temperature field control system, a fluid loading control system and a fluid seepage measurement system;

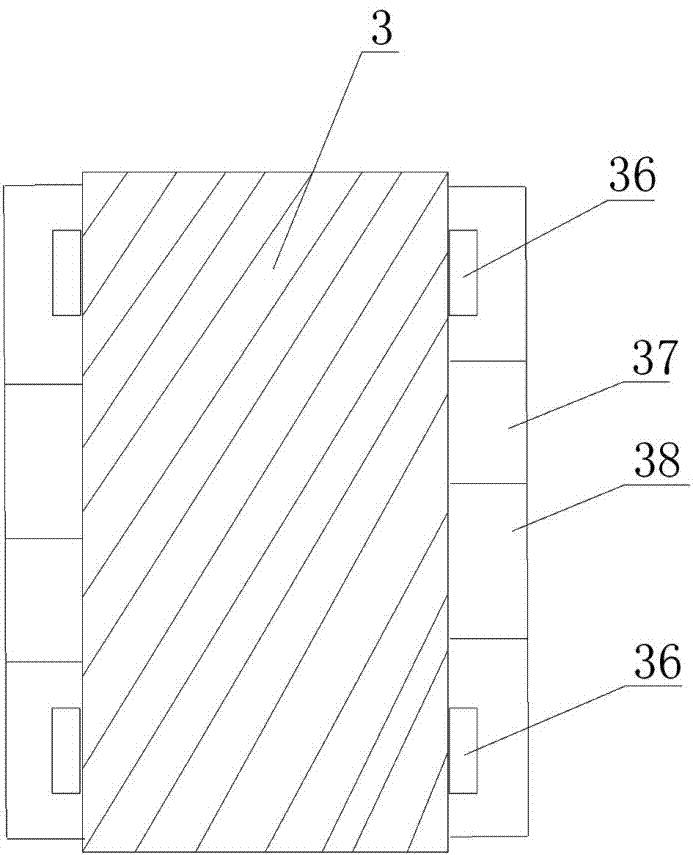

[0058] The device body is provided with an experimental chamber 1, and the experimental chamber 1 is provided with a bearing platform 2, a rock sample 3, an indenter 4, a metal gasket 5, a heat shrinkable tube 6 and a cold bath 7, and the bearing platform 2 is arranged in the experimental chamber 1 Inside, the upper and lower ends of the rock sample 3 are provided with temperature sensors, and the rock sample 3 is provided with an axial extensometer and a radial extensometer. The tube 6 is set in the cold bath tank 7, the indente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com