PCB detection sorting system and method based on machine vision

A machine vision detection and machine vision technology, applied in sorting and other directions, can solve the problems of slow visual inspection, inability to change the detection area and parameters, affecting work efficiency, etc., to reduce costs and system running time, and speed up production inspection efficiency. , the effect of improving efficiency and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the present embodiments are not intended to limit the present invention.

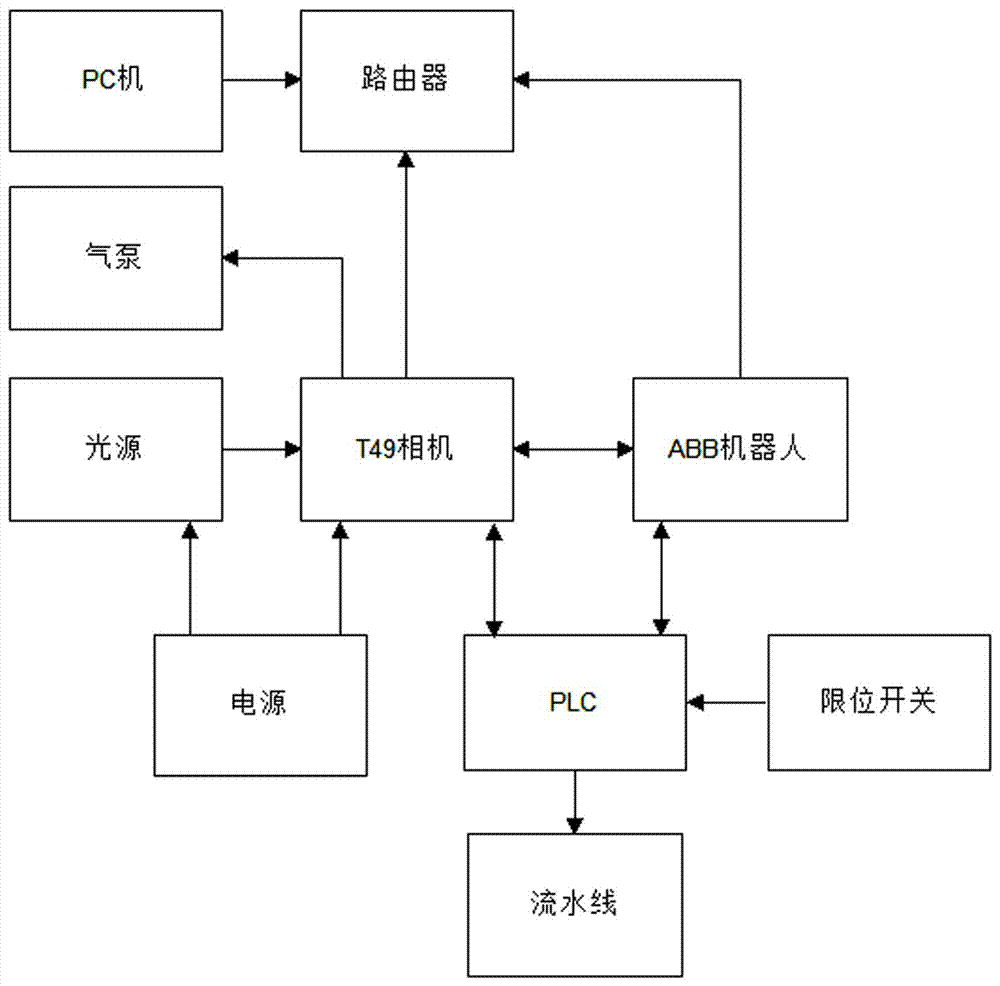

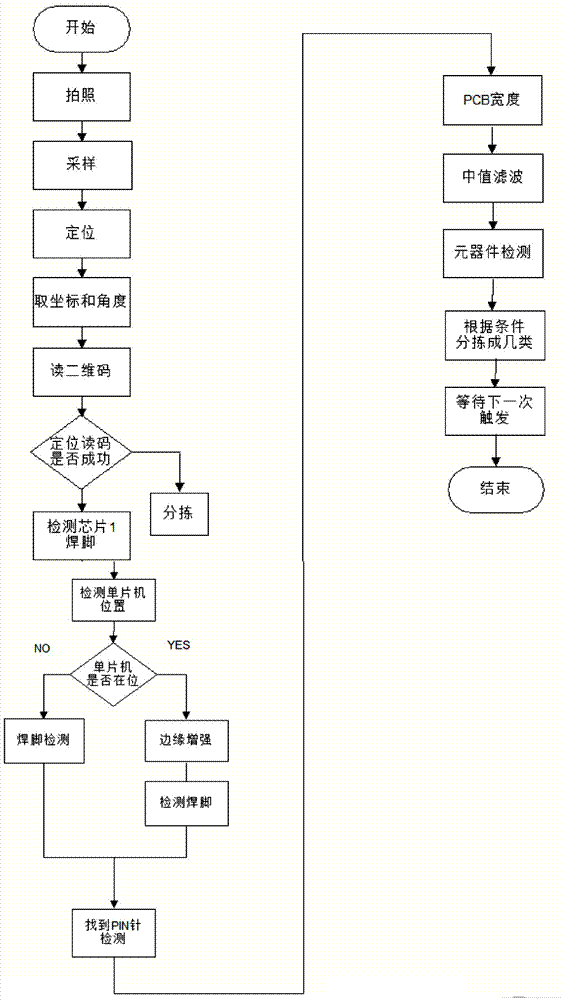

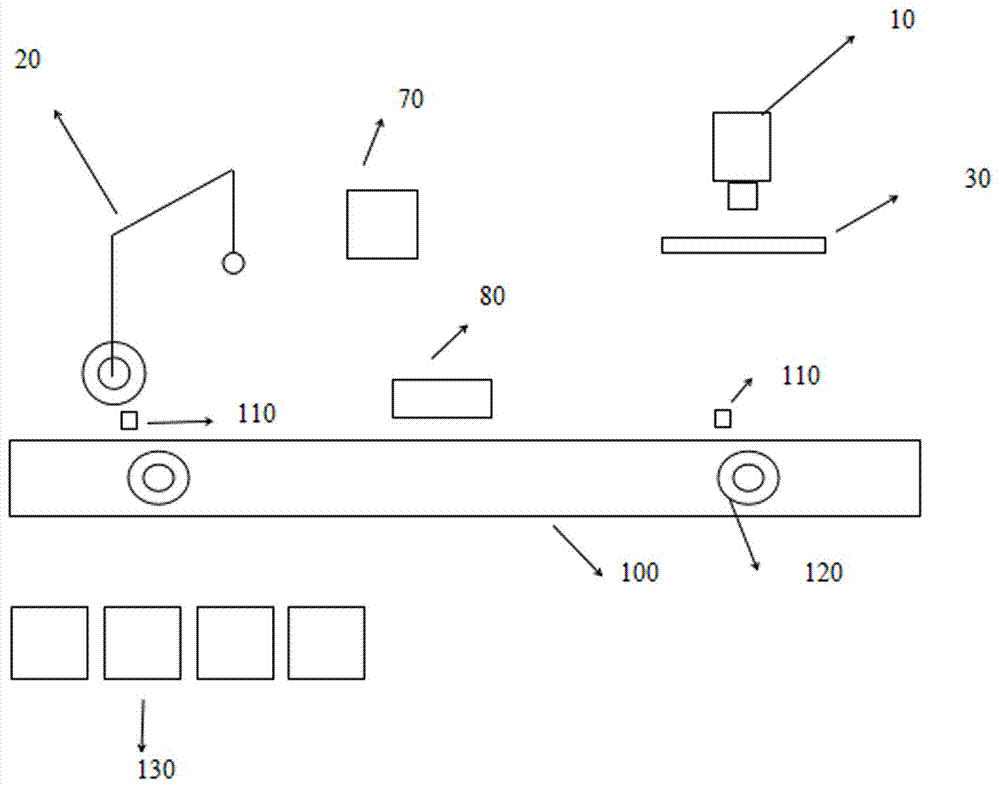

[0040] see figure 1 As shown, the present invention discloses a PCB detection and sorting system based on machine vision, including a smart camera 10, an industrial robot 20, a light source 30, a bracket 120, a router, a PC and a power supply, a vacuum air pump 70, a PLC controller 80, Limit switches 90, 110 and assembly line 100.

[0041] The smart camera 10 has a built-in microprocessor, which is used to collect images and complete image processing, and can communicate with the industrial robot 20 through the serial port; the data communicated between the smart camera 10 and the industrial robot 20 includes transmission of XY coordinates, angle values, and sorting positions. 1. Control the I / O command of the air nozzle; the optical lens on the smart camera 10 needs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com