Safe net hood frame welding machine

A welding machine and net cover technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting welding quality and quality stability, poor positioning stability of skeleton and frame, increasing equipment and manpower, etc. , to achieve the effect of improving welding quality and quality stability, saving time and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

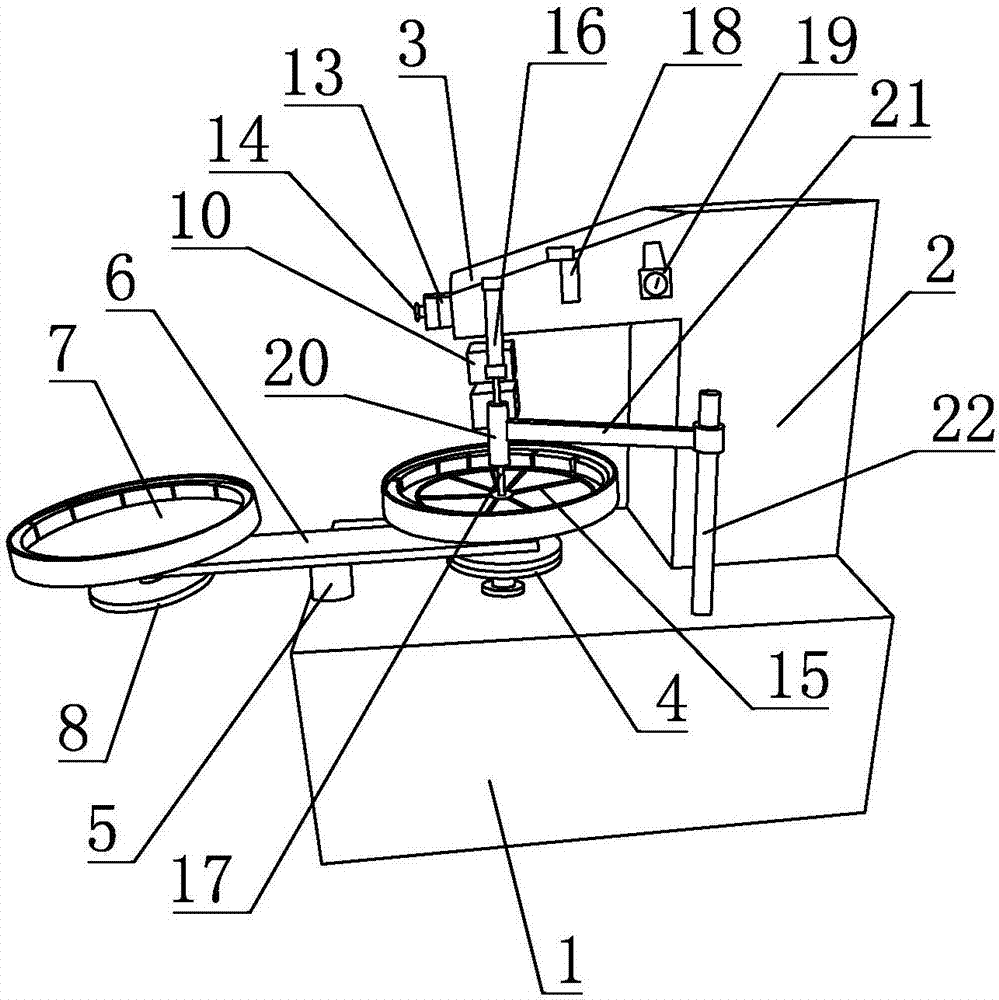

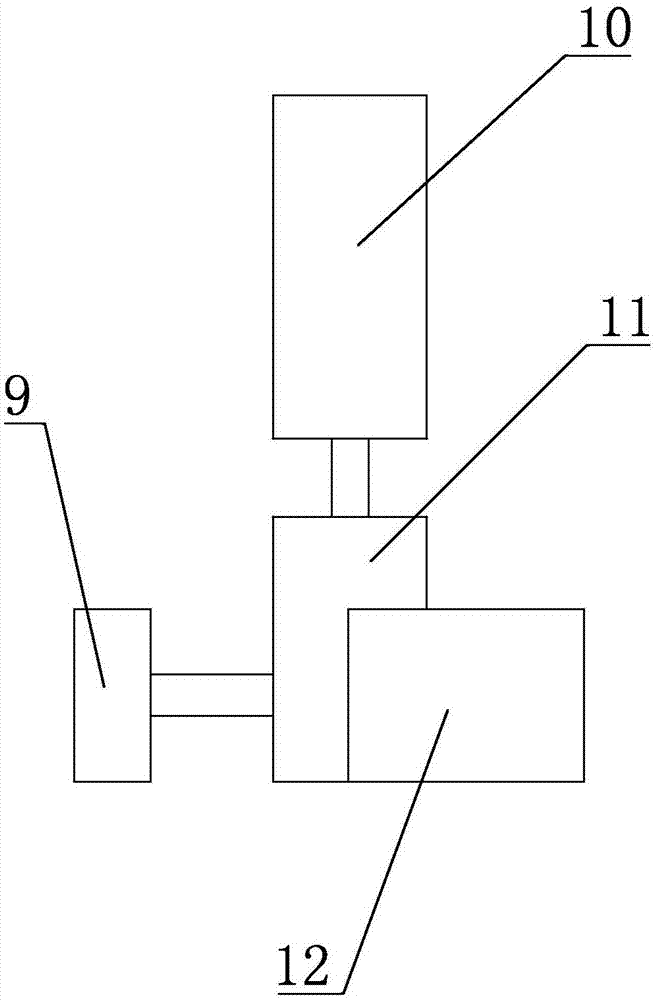

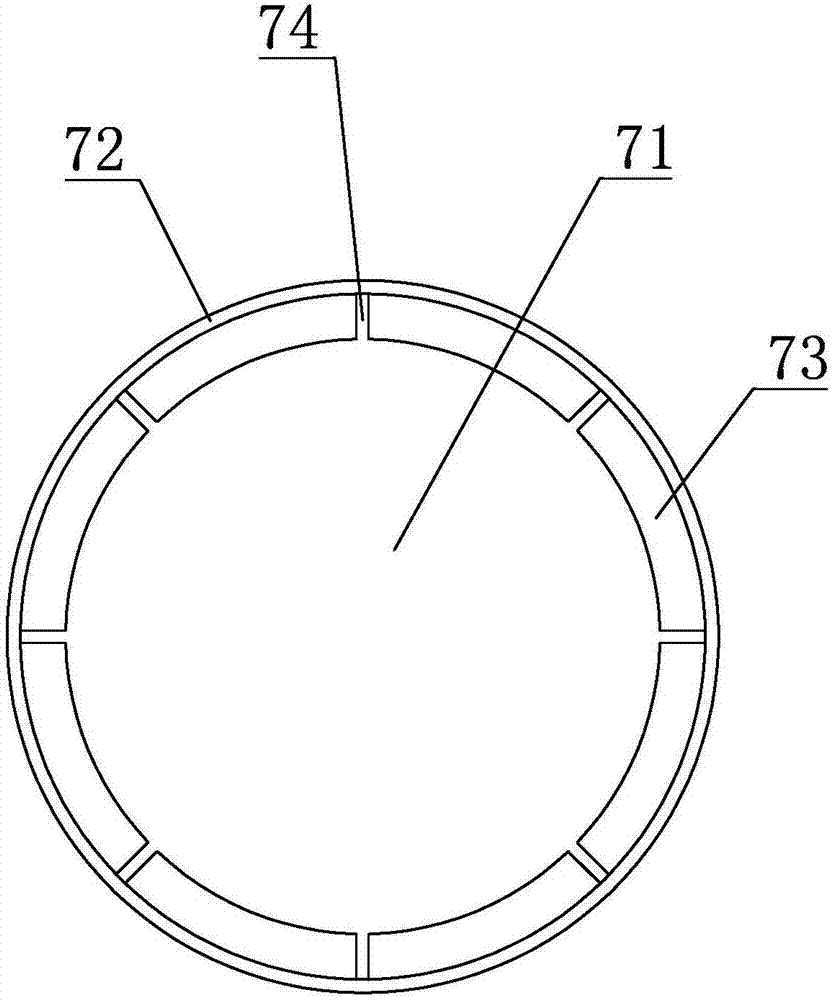

[0017] refer to Figure 1 to Figure 4 , a safety net frame welding machine, including a machine 1, a frame 2 arranged on the machine 1, a welding machine and a control system, the frame 2 is fixed on the rear of the machine 1, and its upper part is provided with a The front cantilever 3, the machine platform 1 below the cantilever 3 is provided with a drive plate 4 that can rotate with equal clearance, the machine platform 1 on the front side of the drive plate 4 is provided with a support column 5, and the top of the support column 5 is provided with a middle The steering beam 6 that is rotatably connected thereto, the two ends of the steering beam 6 are provided with a rotatable positioning plate 7, the upper edge of the inner ring of the positioning plate 7 is adapted to the frame 24, and the lower side is also provided with a drive plate 4 meshed driven plate 8; the cantilever 3 is provided with a welding block 9 that can be controlled by the control system to move up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com