Multi-functional mechanical clamping device

A multi-functional machine and clamping device technology, applied in the directions of manipulators, program-controlled manipulators, claw arms, etc., can solve the problems of inconvenient use by staff, inconvenient adjustment of the clamping device, and difficulty in ensuring stable performance, and achieve suitable promotion and use. , good economic and social benefits, high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

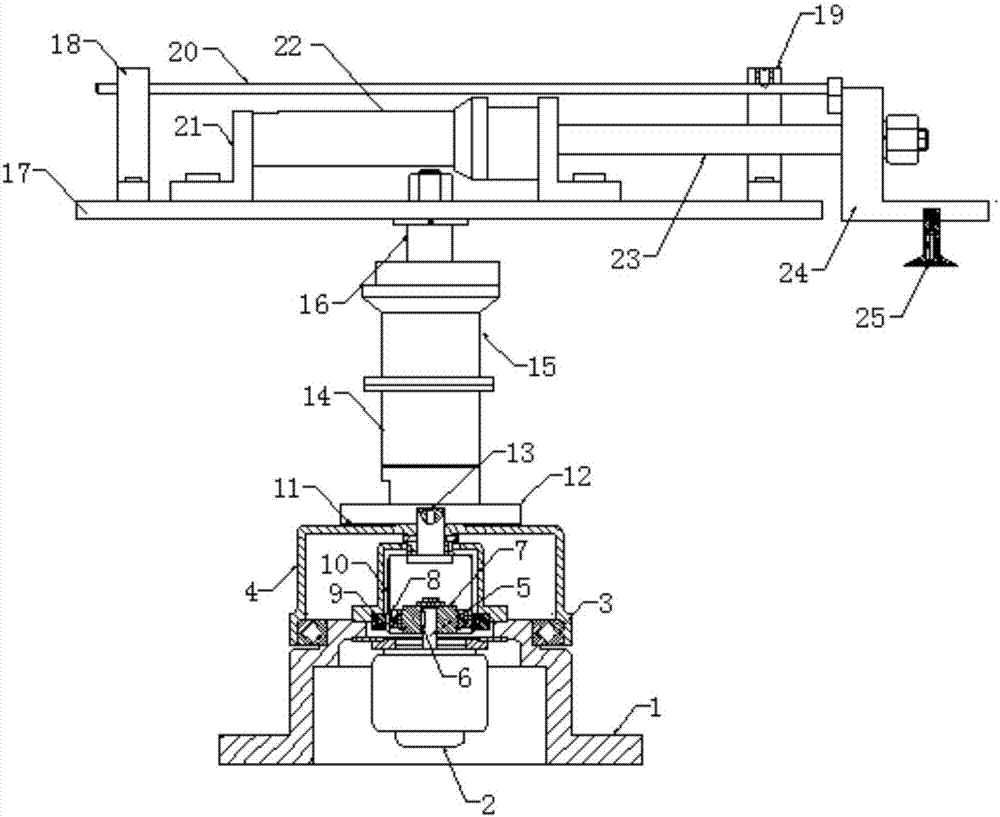

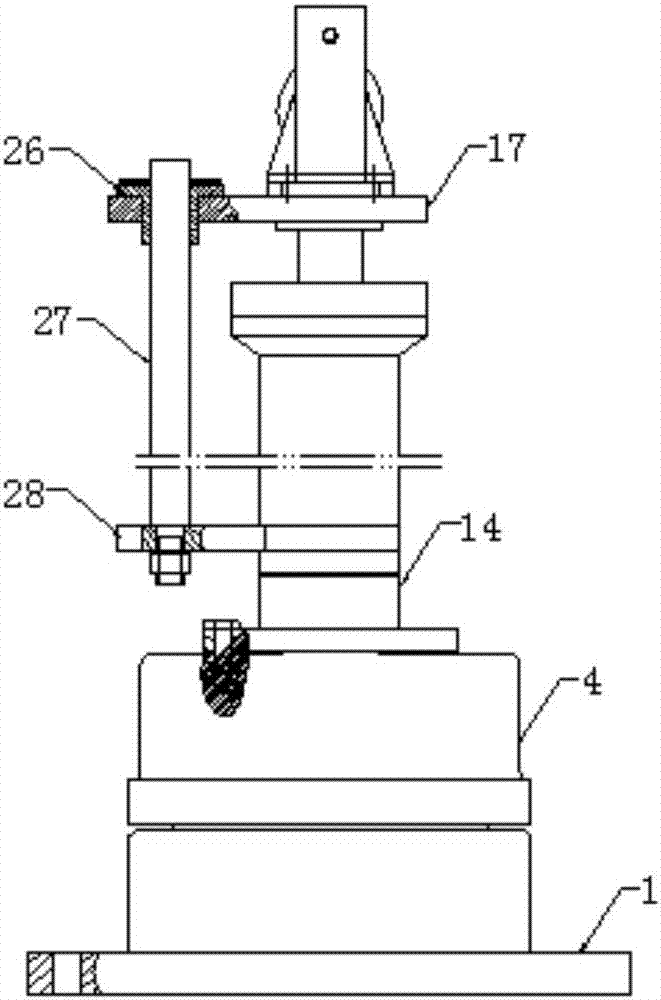

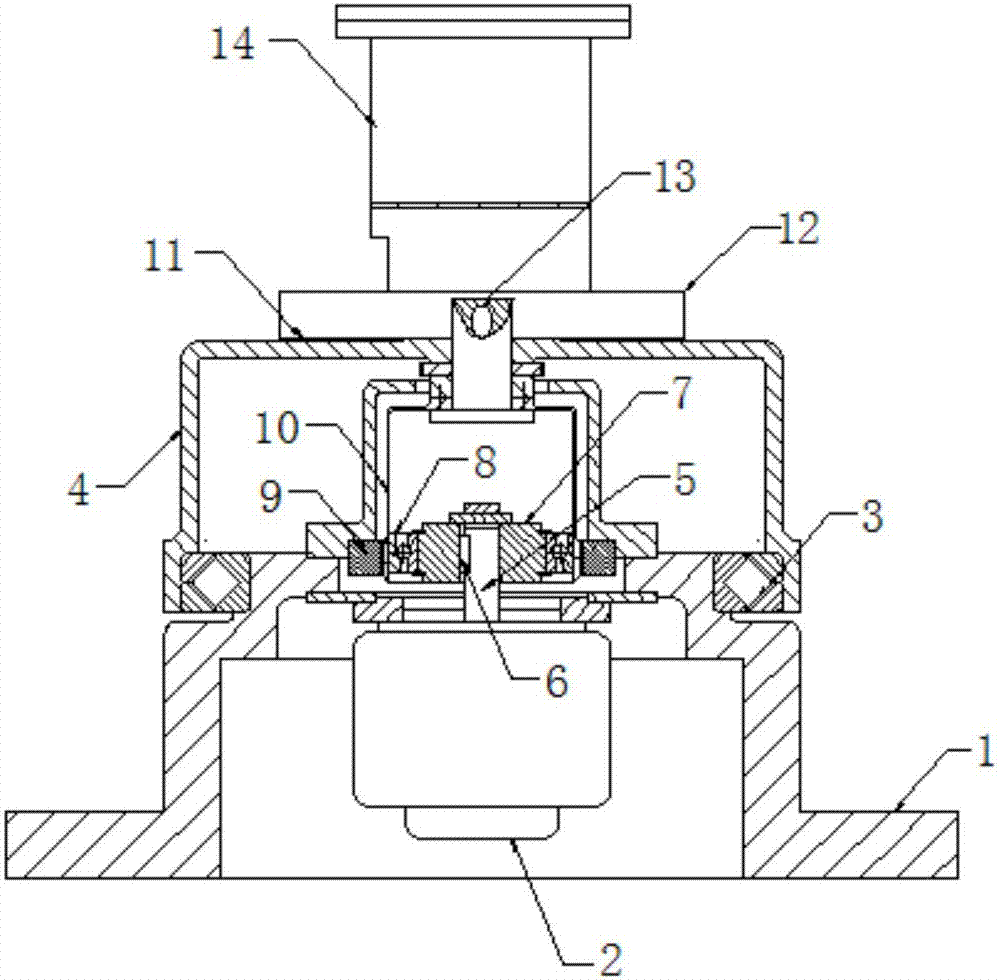

[0021] like Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a multifunctional mechanical clamping device, including a base 1, a stepping motor 2, a thin-walled sealed cross roller bearing 3, a rotating body 4, a drive shaft 5, and a key pin 6. Harmonic generator 7, angular thrust bearing 8, steel wheel 9 and flex spline 10; the top opening of the base 1 is nested with a thin-wall sealed cross roller bearing 3, and the base 1 passes through the thin-wall sealed cross roller The bearing 3 is movably connected with a rotary body 4, the base 1 is fixedly installed with a stepping motor 2, the rotary body 4 is equipped with a flex spline 10, and the stepping motor 2 is connected with a harmonic generator 7 through a drive shaft 5 at one end thereof, In addition, a key pin 6 is embedded between the drive shaft 5 and the harmonic generator 7, and an angular thrust bearing 8 is fixedly connected to the outside of the harmonic generator 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com