Power panel for robot and robot

A technology of robots and power boards, applied to instruments, simulators, manipulators, etc., can solve the problems of fixed functions, few functions, and the inability to develop and upgrade chips, and achieve reliable control and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

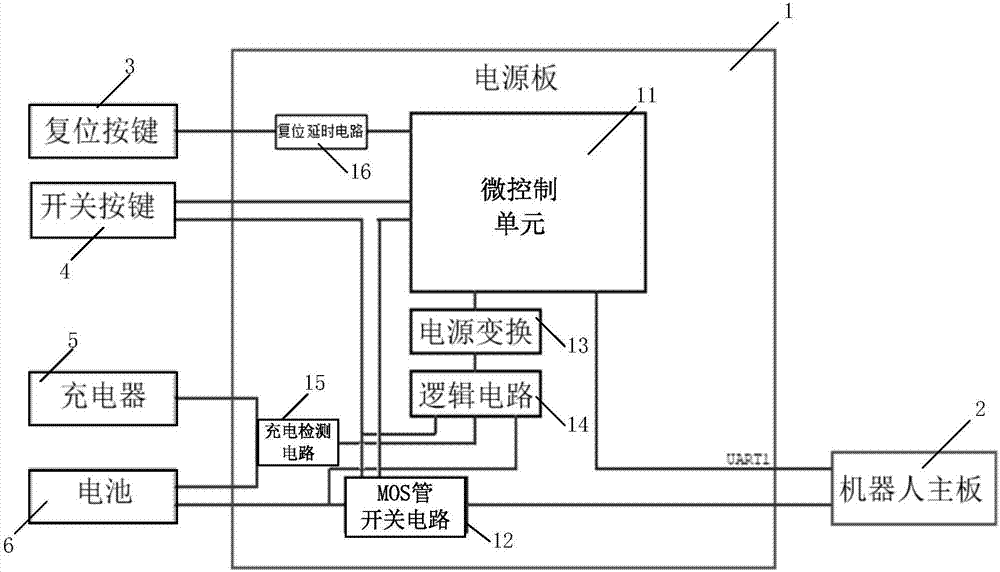

[0021] Such as figure 1 What is shown is a schematic diagram of a power board for a robot according to an embodiment of the present invention.

[0022] refer to figure 1 , The power board 1 includes a micro control unit 11 , a MOS transistor switch circuit 12 , a power converter 13 , a logic circuit 14 , a charging detection circuit 15 and a reset delay circuit 16 .

[0023] A switch button interface (not shown) is provided on the micro control unit 11 for connecting the switch button 4 . When the micro control unit 11 detects that the switch button 4 is pressed, the battery 6 supplies power to the power board 1, and turns on the power circuit system of the robot. The power conversion 13 provides power for the micro control unit 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com