Timber efficient cutting device with noise-reducing function for furniture production

A cutting device and functional technology, applied in the field of high-efficiency wood cutting devices for furniture production, can solve problems such as the life and health of critical operators, not cutting straight, and wood shaking from side to side, avoiding hand contact with the cutting wheel and avoiding irreversible damage. Damage, avoid the effect of rebounding too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

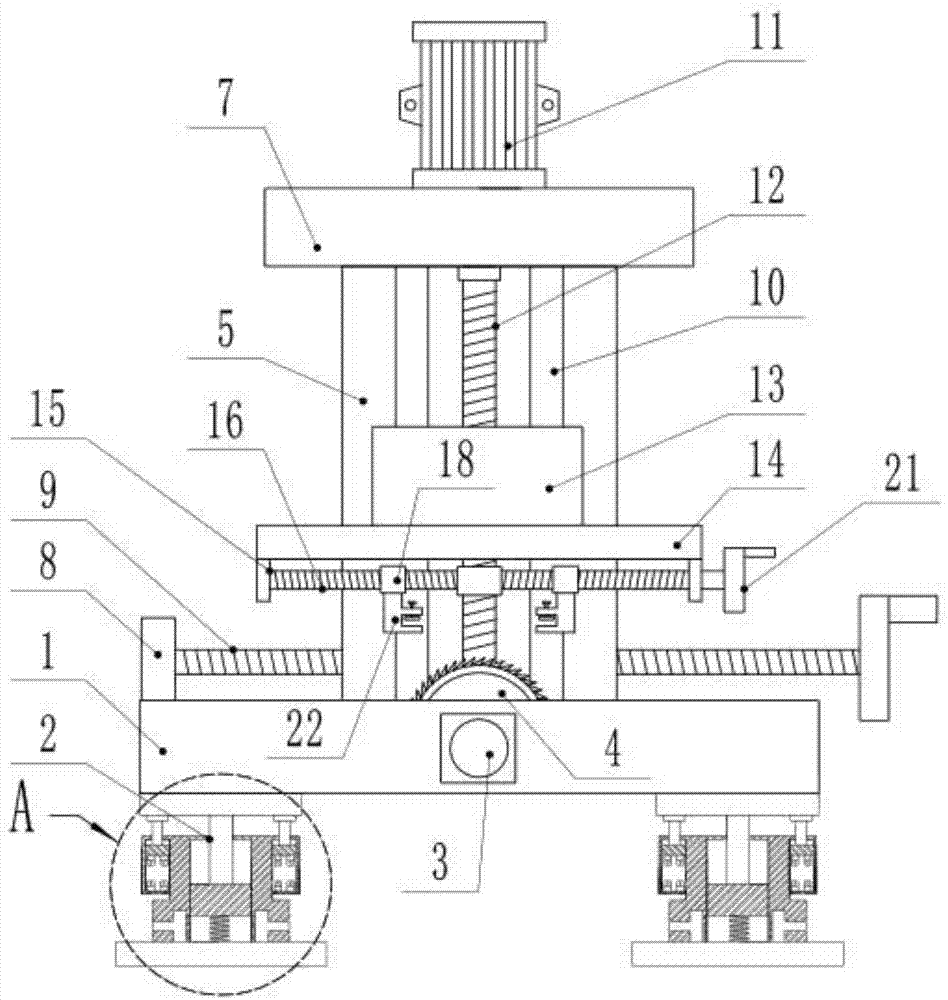

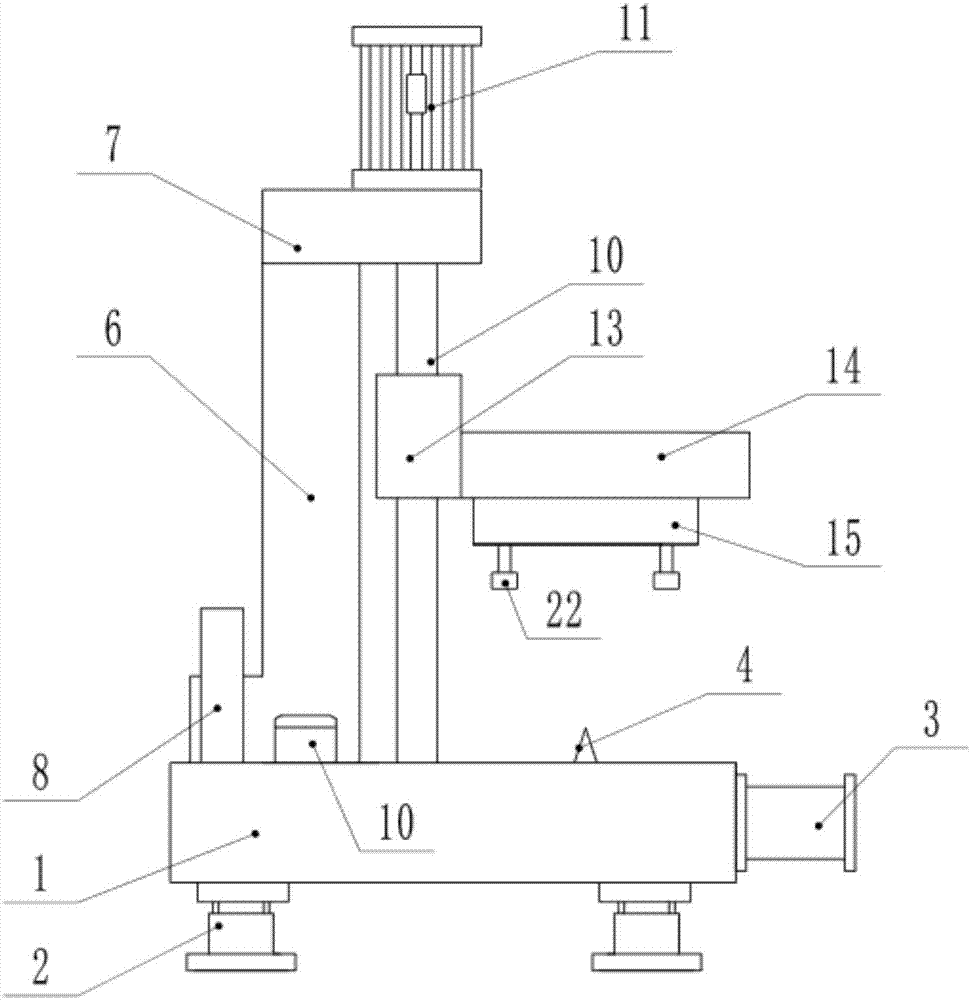

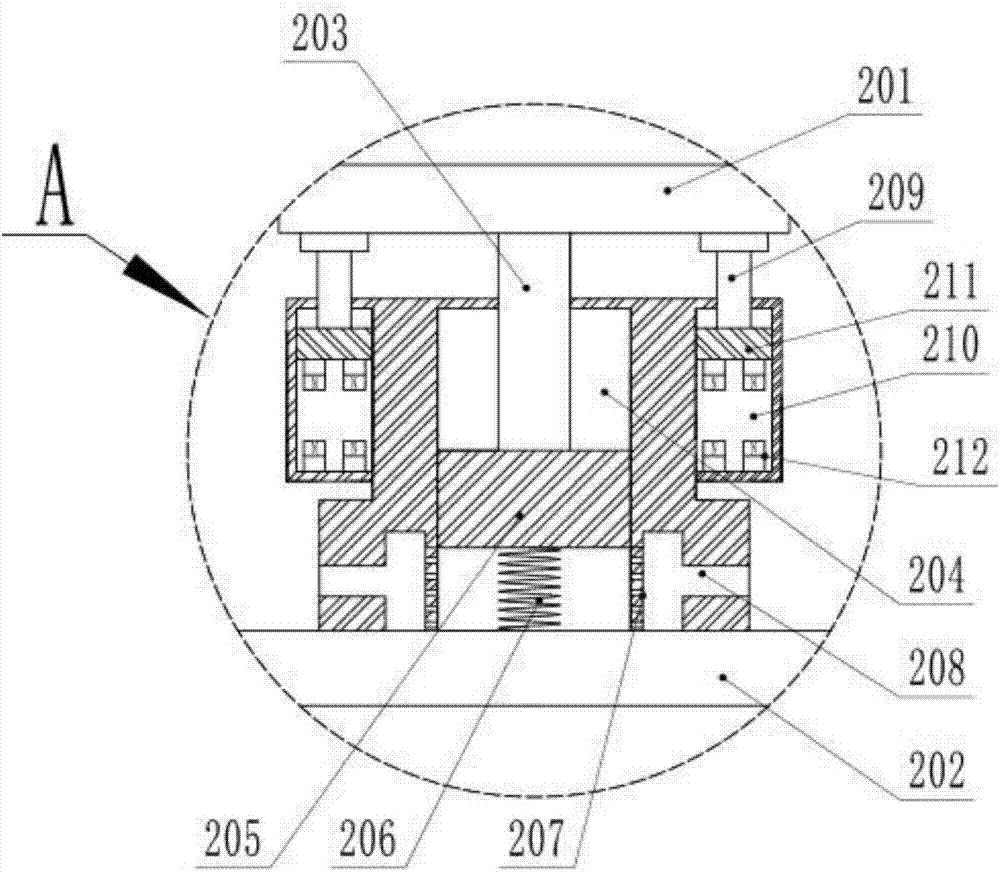

[0022] see Figure 1-5 , a high-efficiency wood cutting device for furniture production with noise reduction function, comprising a cutting table 1, a shock absorbing device 2, a cutting motor 3, a cutting wheel 4, a first screw 9, a guide column 10, a second screw 12 and The fixture 22 is fixed, the shock absorber 2 is installed on the lower side of the cutting table 1, and there are at least four groups of the shock absorber 2. The lower side of the shock absorber 2 is equipped with a connecting block 201, and the lower side of the connecting block 201 is welded with the first A piston rod 203, the first piston rod 203 is vertically downward and penetrates into the first piston cavity 204 inside the shock absorber 2, the first piston rod 203 is connected to the first piston 205 on the lower side, and the first piston 205 lower side A damping spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com