Universal tapered co-directional double-screw-rod extruder for plastic pipes and sheet materials

A twin-screw extruder and plastic pipe technology, applied in the field of plastic extrusion, can solve problems such as damage, unsolved gears, and poor load-bearing capacity, and achieve the effects of prolonging service life, increasing filling length, and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

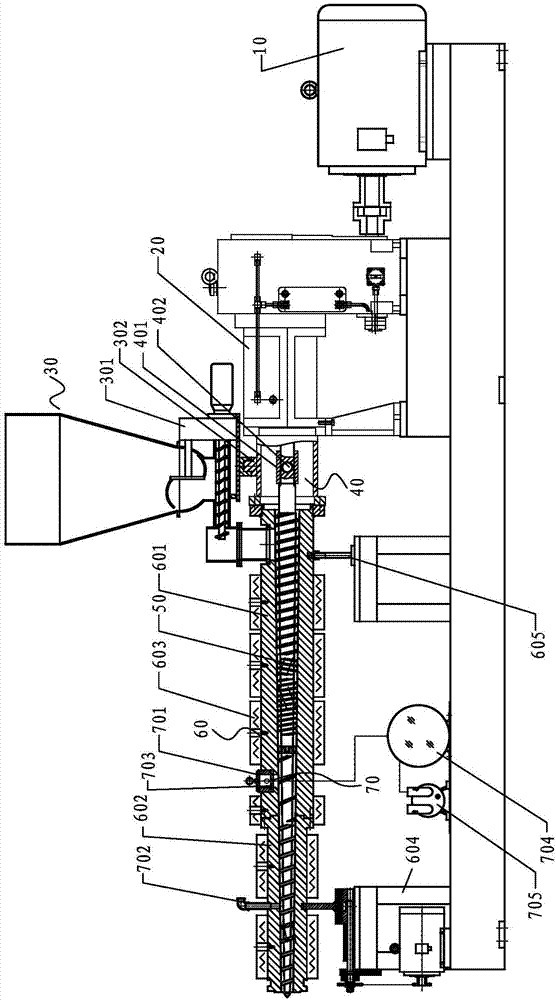

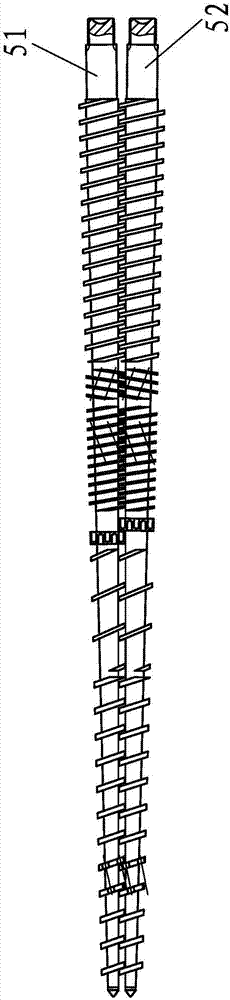

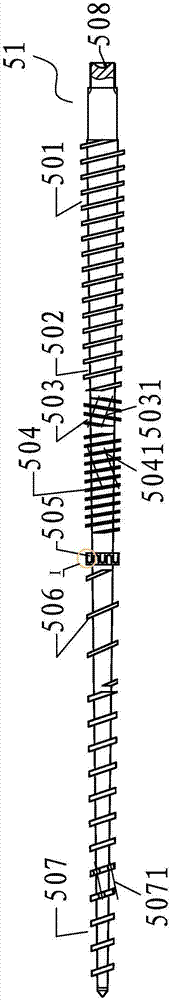

[0038] First, please refer to figure 1 , as a non-limiting embodiment, the general-purpose conical co-rotating twin-screw extruder for plastic pipes and plates of the present invention includes: drive motor 10, deceleration distribution box system 20, feeding system 30, transmission system 40, conical Co-rotating twin screw system 50 , barrel system 60 and exhaust system 70 .

[0039] The driving motor 10 transmits the power to the deceleration distribution box system 20. In the present invention, the deceleration distribution b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com