A continuous fiber reinforced composite material electromagnetic shielding structure 3D printing manufacturing method

A technology for strengthening composite materials and electromagnetic shielding structures, which is applied in the directions of manufacturing tools, additive manufacturing, and additive processing. It can solve the problems of not seeing relevant literature disclosures, and achieve excellent shielding effectiveness, strong mechanical bearing capacity, and reduced density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] A continuous fiber reinforced composite electromagnetic shielding structure 3D printing manufacturing method, comprising the following steps:

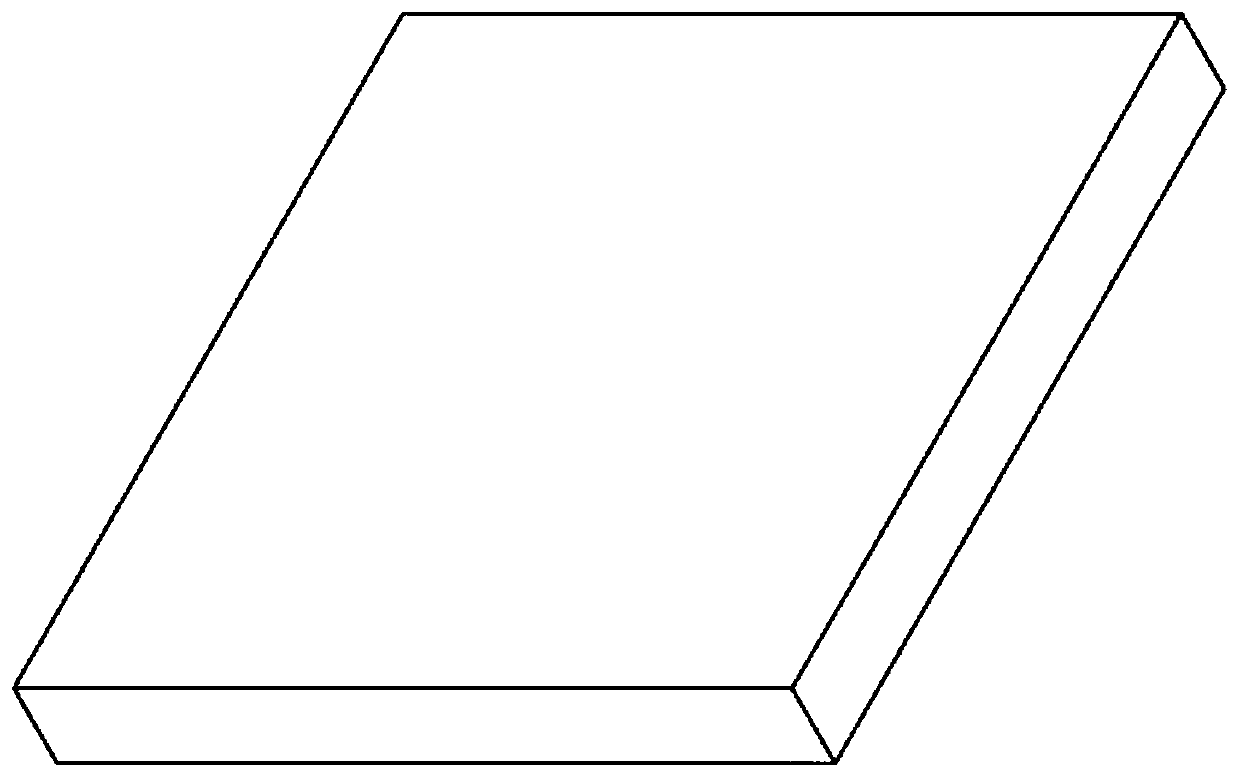

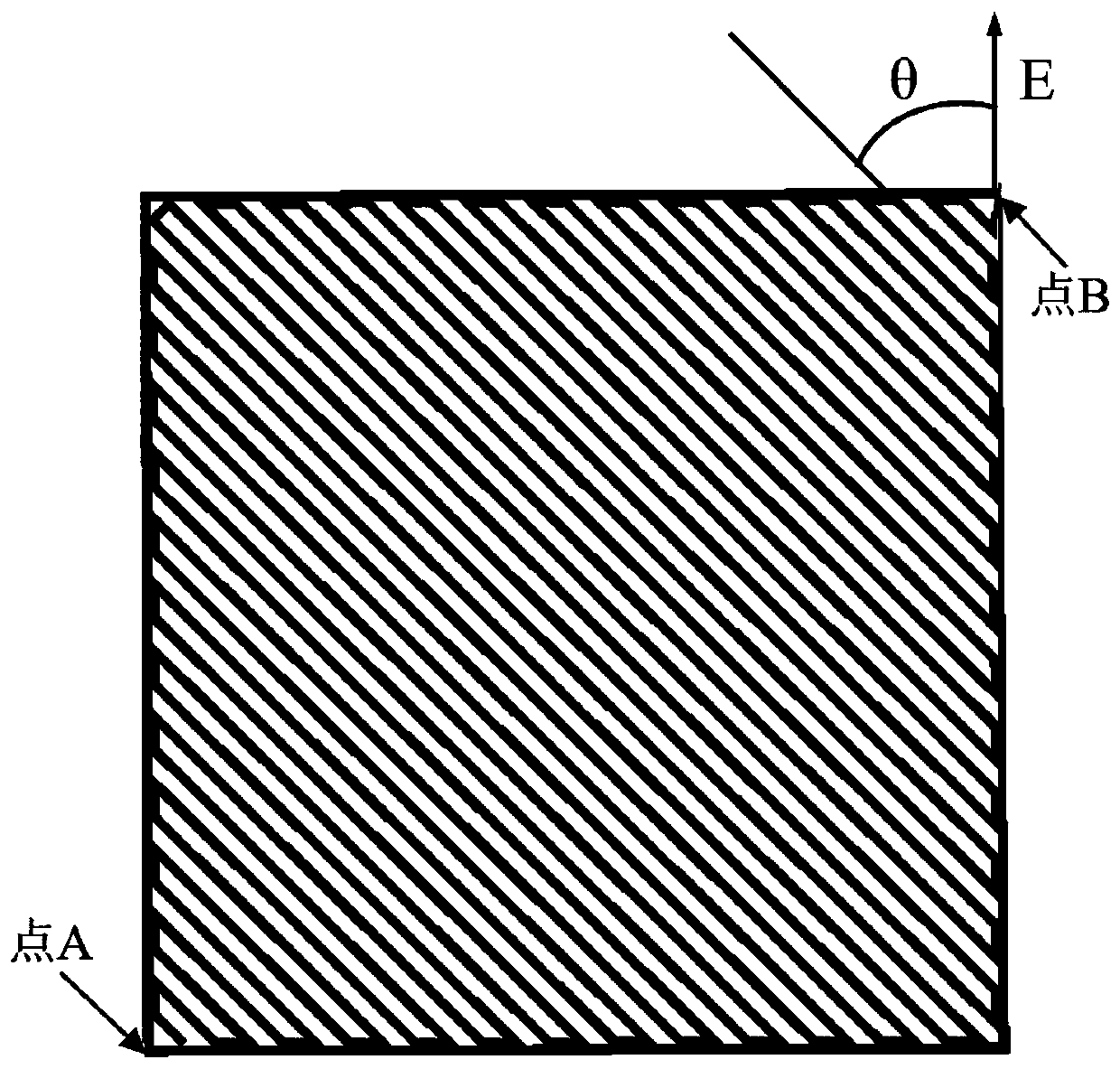

[0027] 1) Establish a 3D model of the shielding structure: refer to figure 1 , according to the requirements of preparing the electromagnetic wave shielding performance test piece, and the convenience of further preparation of the test piece, use the computer-aided design software CAD Solidworks to build a 45 × 45 × 5 three-dimensional model of the original sample, and export the model as a file in stl format;

[0028] 2) Design conductive fiber path: According to the requirements of absorption attenuation (SEa), reflection loss (reflection attenuation, SEr) and overall shielding effectiveness (shielding effectiveness, SE) of the shielding structure, design and plan the conductive fiber inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com