Embossing machine for cigarette filter stick fiber paper

A cigarette filter rod and fiber paper technology, applied in the direction of mechanical processing/deformation, can solve the problems of limited popularization and application, different suction resistance of cigarettes, etc., and achieve the effects of improving economic benefits, ensuring quality, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

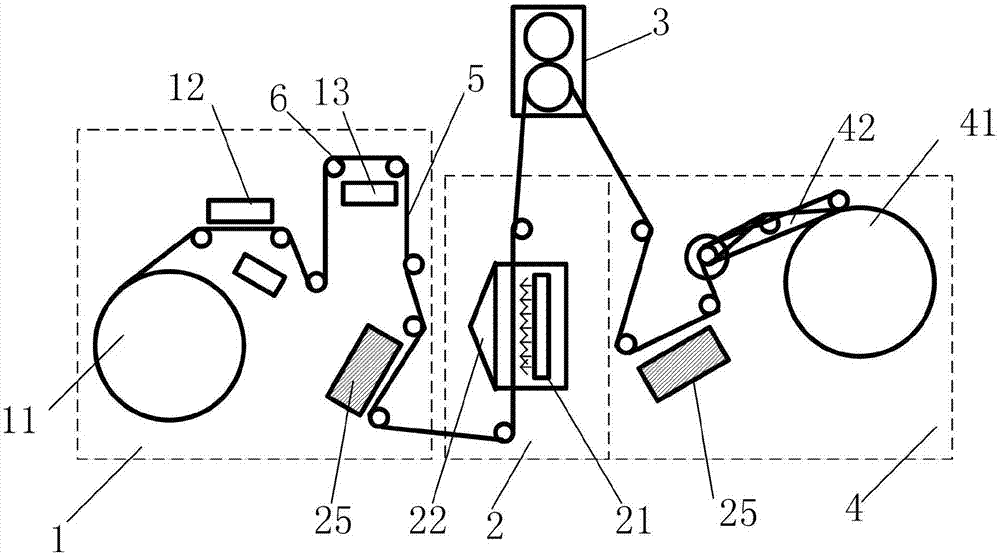

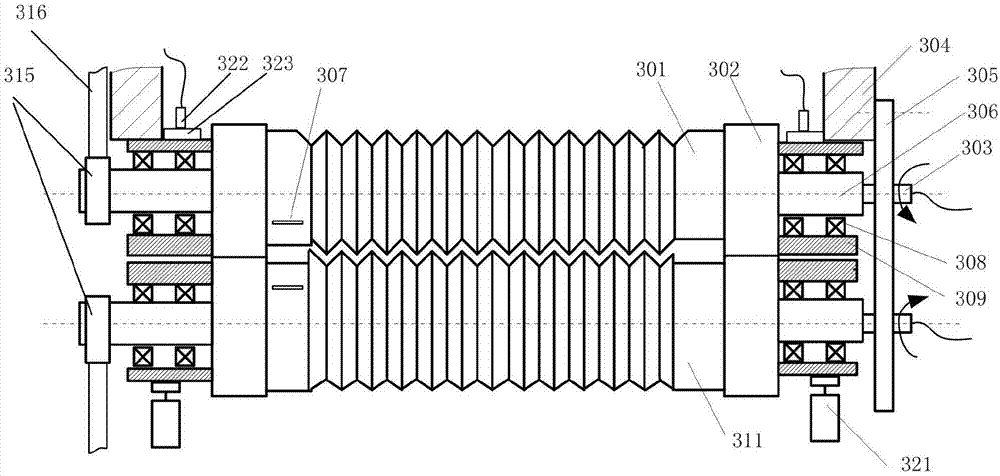

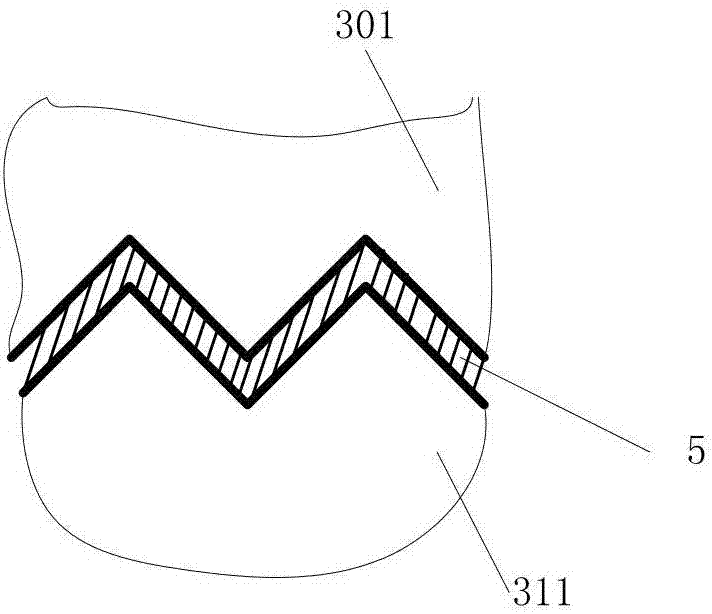

[0038] Such as figure 1 As shown, the cigarette filter rod fiber paper embossing machine of the present invention includes a control unit and an unwinding unit 1, a heating unit 2, an embossing unit 3, a winding unit 4 arranged in sequence along the moving direction of the paper 5, and several supporting Roller 6 for paper 5 .

[0039] 1. Unwinding unit 1

[0040] The unwinding wheel 11 makes the fiber paper 5 unfold under the action of the magnetic powder brake, and the fiber paper 5 is provided with a tension sensor 12, and the tension sensor 12 and the magnetic powder brake of the unwinding unit 1 form a closed-loop control to ensure that the tension of the paper 5 remains constant, and Tension can be set artificially. A deviation correcting device 13 is also provided at the position of the unwinding unit 1 of the paper 5, and an infrared detection head is used for detection to realize deviation correction during the middle process of the paper 5 running, so as to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com