Scroll compressor with both gas supplement function and intermediate gas exhaust function and heat pump system

A scroll compressor and functional technology, applied in the field of scroll compressors, can solve the problems of low working efficiency, waste of energy, over-compression, etc. The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

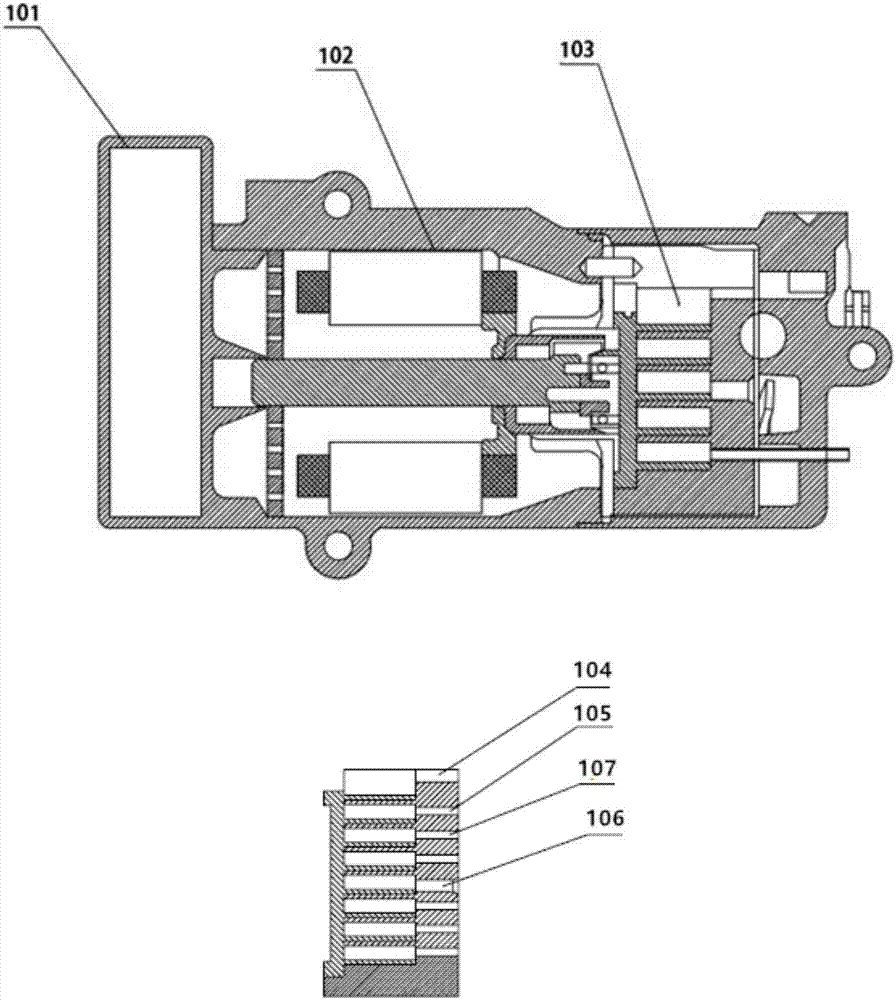

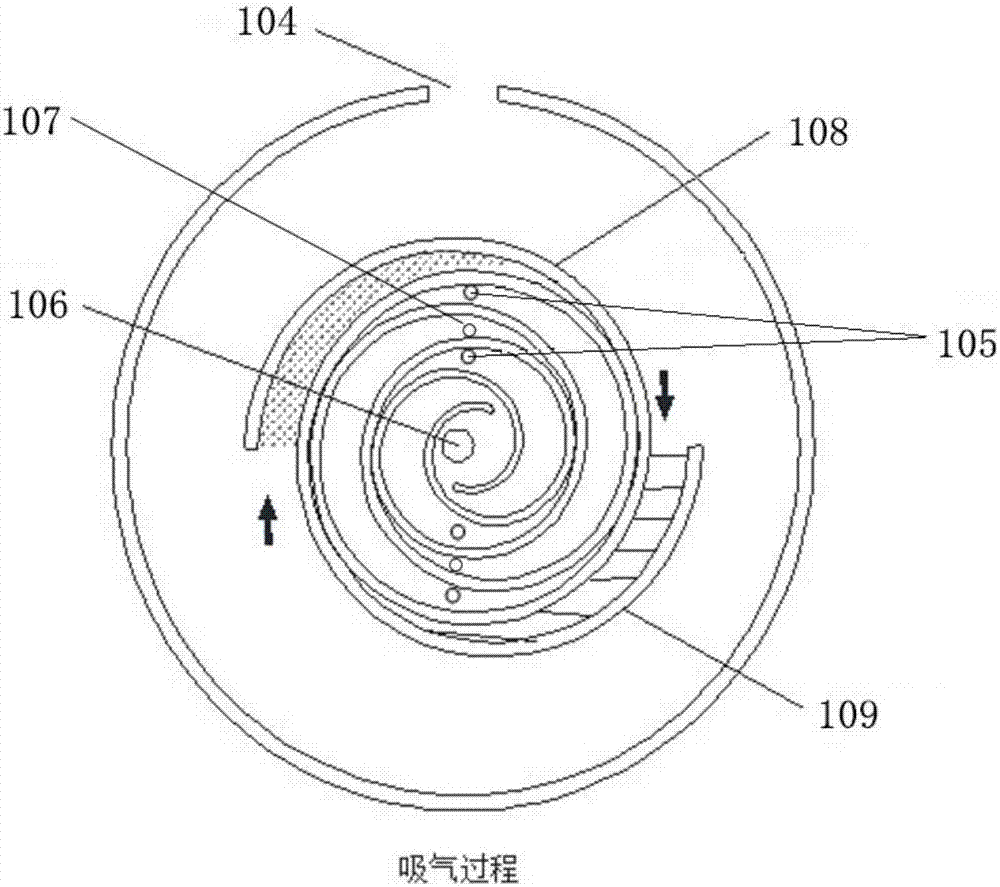

[0023] Such as figure 1 and figure 2 As shown, this embodiment discloses a scroll compressor 1 with the functions of supplementing air and intermediate exhausting, including a control part 101, a motor part 102 and a compression part 103 connected sequentially in the body, and the compression part 103 is set There is a pair of symmetrically arranged scrolls, namely a fixed scroll 109 and a movable scroll 108, wherein the fixed scroll 109 is fixed, and the movable scroll 108 performs circular translation within a predetermined range. An air suction port 104 is opened on the outermost side of the fixed scroll 109 , and an exhaust port 106 is opened at the center of the top end face of the fixed scroll 109 .

[0024] The scroll compressor 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com