Flow control device and manufacturing method

A technology for flow control devices and control components, applied in valve devices, sliding valves, valve details, etc., can solve problems such as excessive deformation, damage, internal leakage, etc., and achieve the effect of improving internal sealing performance and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

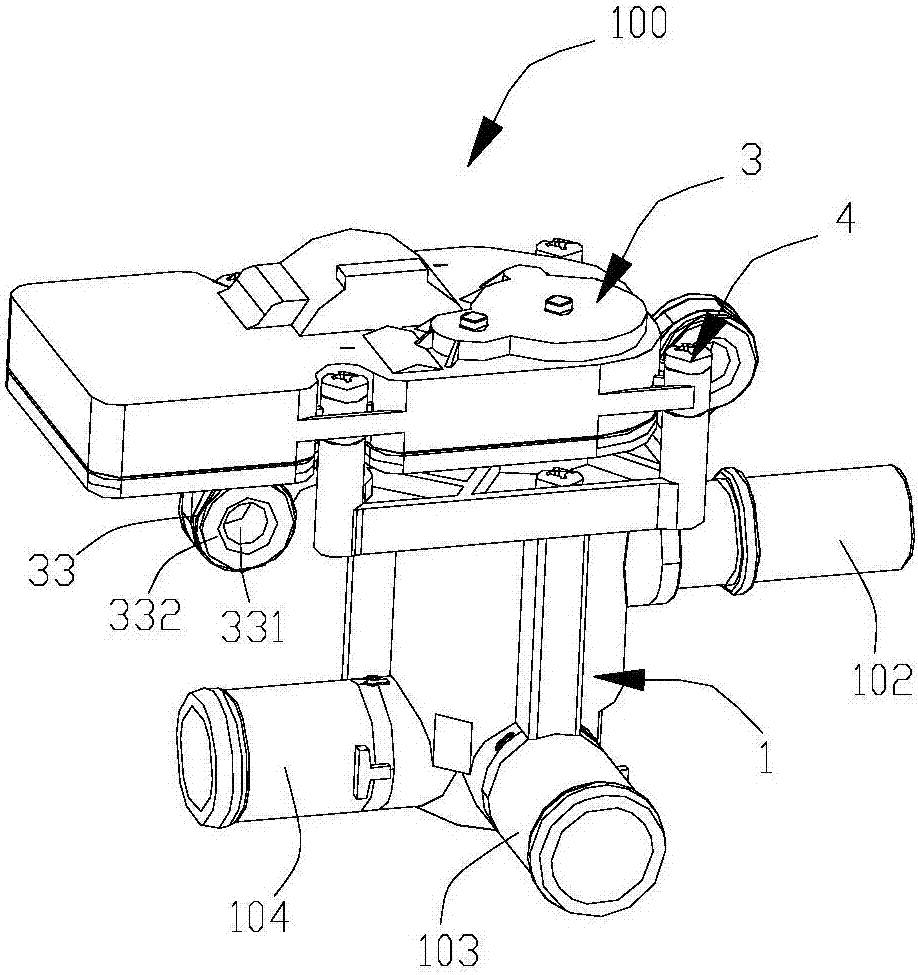

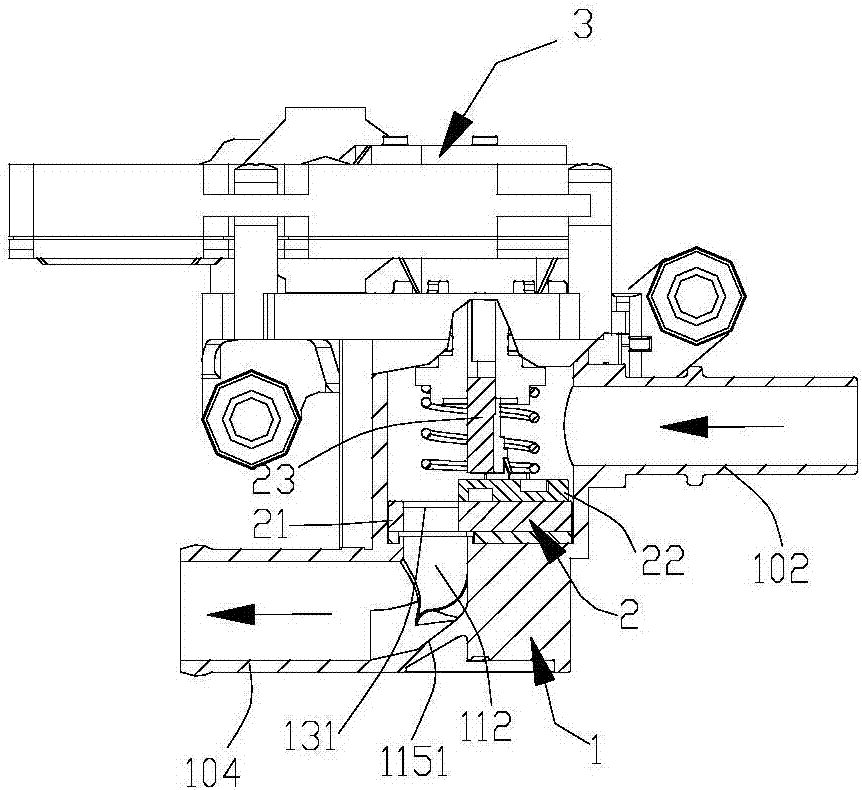

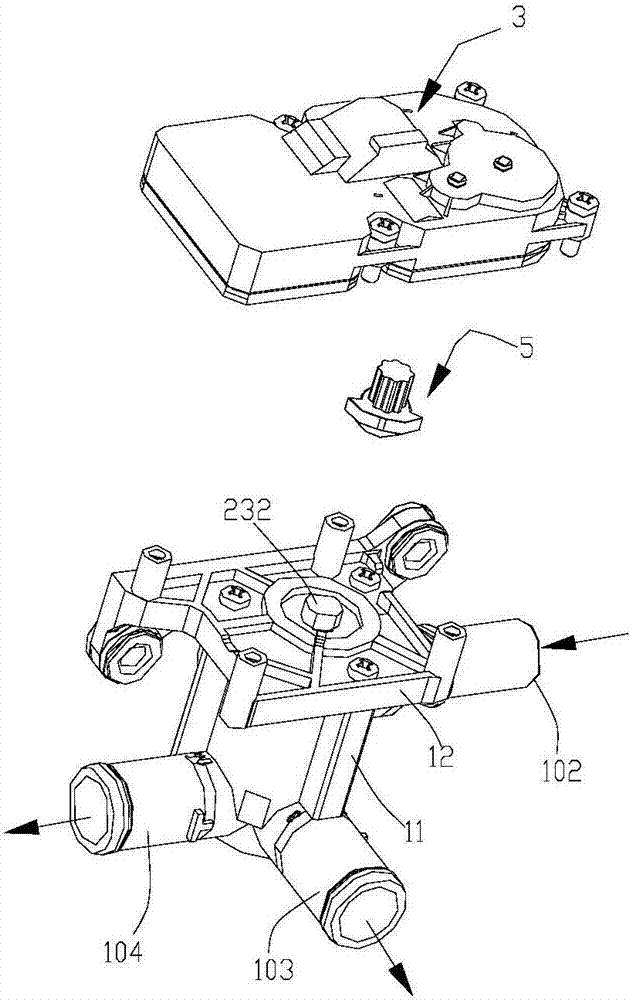

[0027] see Figure 1 to Figure 5 As shown, the flow control device 100 can be applied to heat exchange systems, such as vehicle air-conditioning systems or household air-conditioning systems, etc. Specifically, the flow medium controlled by the flow control device can be water, a mixed liquid of water and other liquids Or other cooling liquids with thermal conductivity, the flow control device controls the distribution of the flow medium and enables the flow medium to exchange heat with other working media of the heat exchange system, and then controls the outlet flow rate of the medium distributed by the flow control device The flow medium of the flow path of the heat exchange system can improve and optimize the control performance of the flow path of the heat exchange system.

[0028] The flow control device 100 can be used for new energy vehicle air conditioners such as HVAC, battery cooling or battery heating systems. Through the setting of the multi-pass structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com