Inductive non-metallic ultrasonic emitting system

A transmitting system, ultrasonic technology, applied in the generation of ultrasonic/sonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, electrical pulse generator circuits, etc. It can reduce the volume, eliminate potential safety hazards, reduce design cost and development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

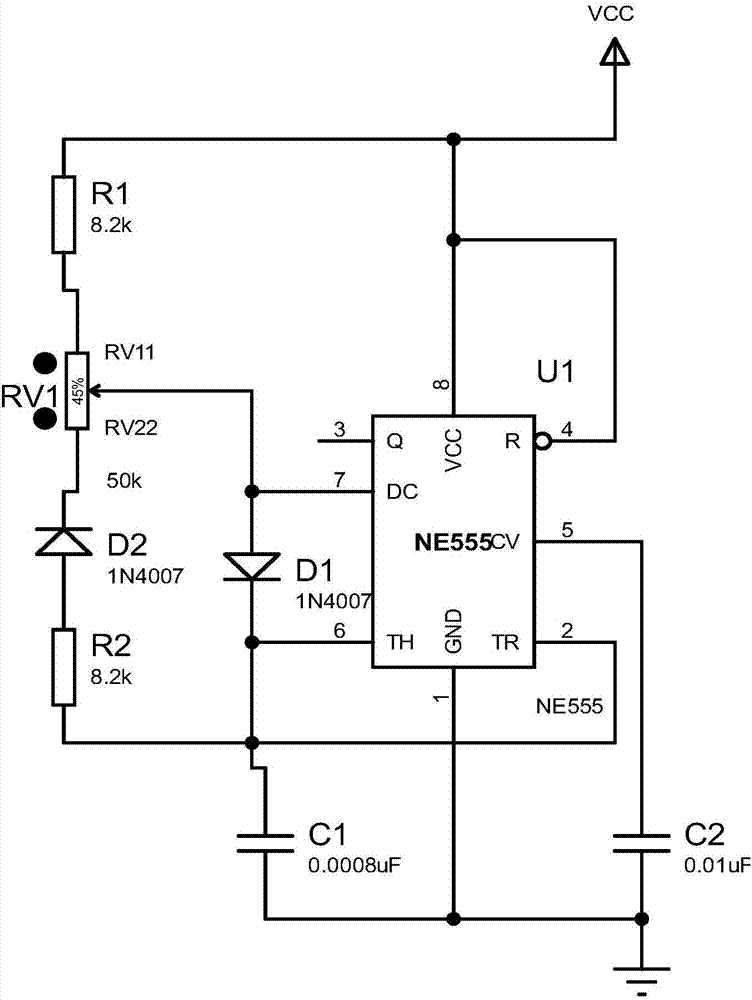

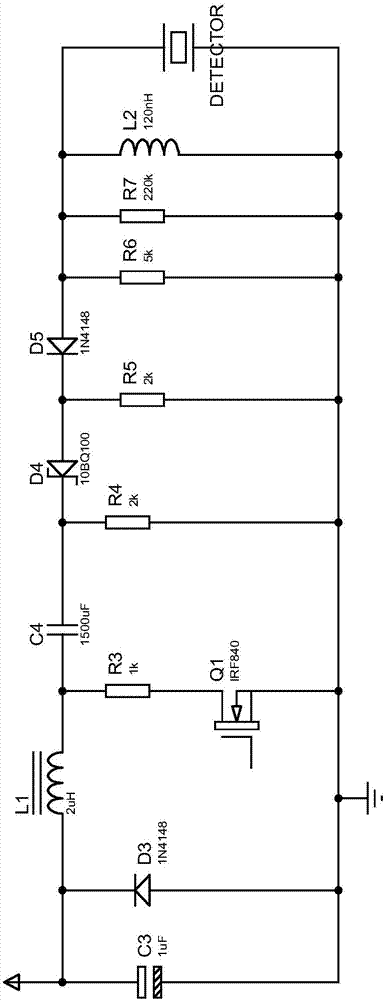

[0019] The invention provides an ultrasonic probe drive circuit that does not require high-voltage power supply and has convenient parameter adjustment. It includes two parts: a square wave generator with adjustable duty ratio and an ultrasonic transmitting circuit. The square wave generator with adjustable duty cycle such as figure 2 shown.

[0020] figure 2 It includes NE555 integrated chip U1, resistor R1, resistor R2, sliding resistor RV1, capacitor C1, capacitor C2, diodes D1 and D2 as switching elements. Connect pins 6 and 2 of NE555 together, and connect capacitor C1 between ground and ground. Connect capacitor C2 between pin 5 of NE555 and ground. Diode D1 is connected between pin 6 and pin 7 of NE555, the anode of D1 is connected to pin 7 of NE555, and the cathode of D1 is connected to pin 6 of NE555. Connect resistor R1, sliding rheost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com