Driving mechanism of new-energy automobile driving motor test board

A technology for new energy vehicles and driving motors, which is used in motor generator testing, electrical components, electromechanical devices, etc., can solve the problems of complex transmission structure, long transmission structure, and increased cost, and achieves simplified transmission structure, simple and convenient operation, The effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

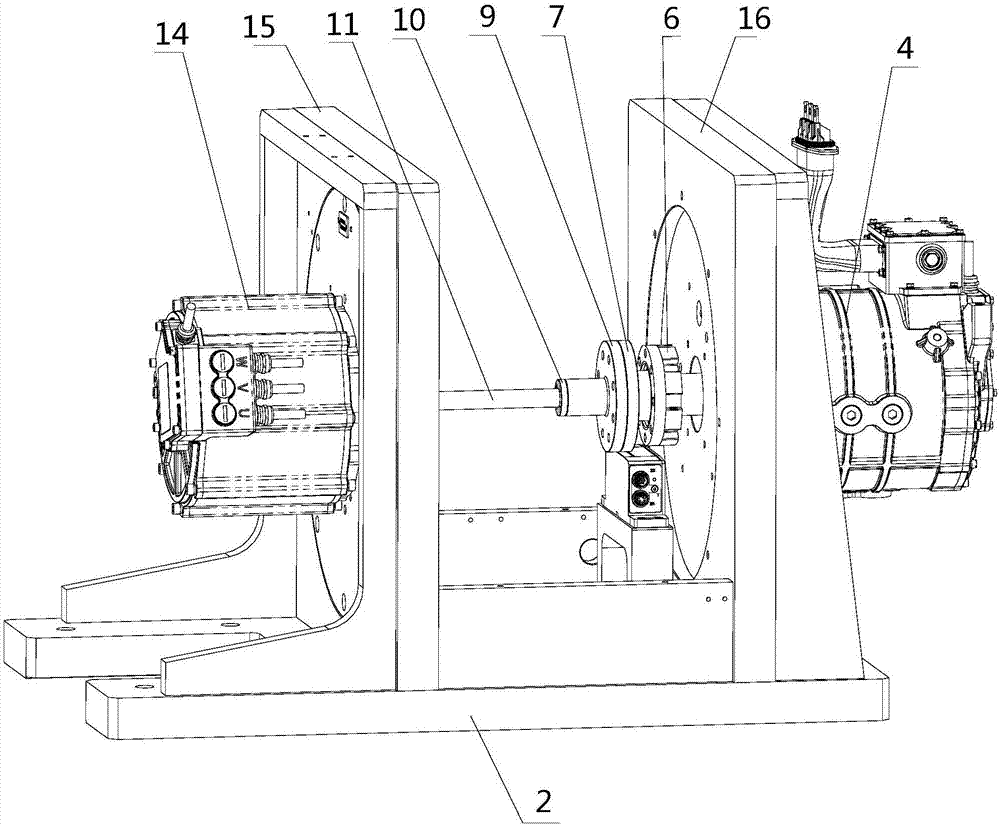

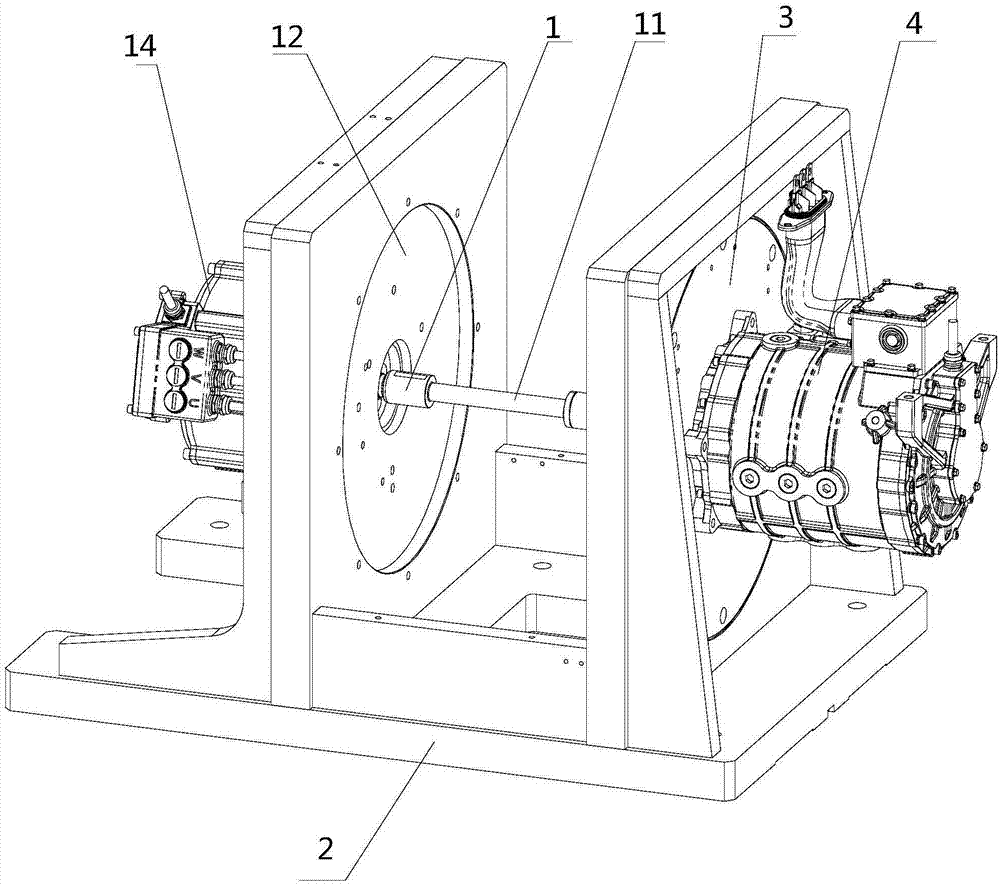

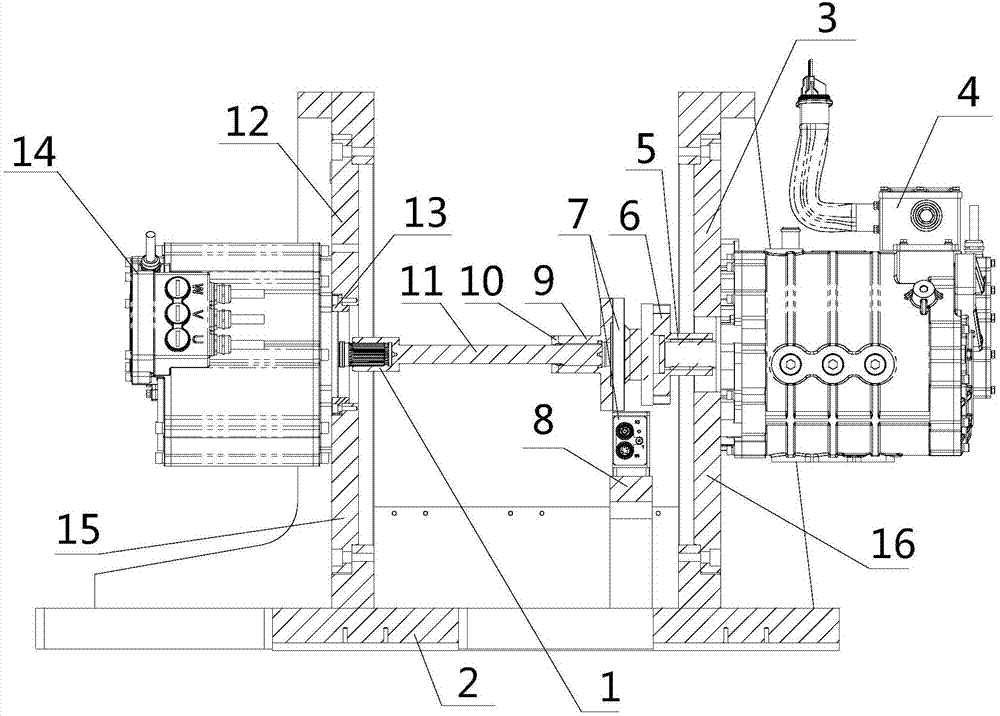

[0024] see Figure 1 to Figure 6 , this embodiment discloses a new energy vehicle drive motor test bench transmission mechanism, including a mounting bracket 2, the mounting bracket 2 is provided with a vertical first vertical plate 15 and a second vertical plate 16, the first vertical plate 15 and The second vertical board 16 is left and right oppositely arranged.

[0025] The center of the second vertical plate 16 has a second step mounting hole 18, and the second step mounting hole 18 is detachably installed with the accompanying test motor mounting plate 3, and the accompanying test motor 4 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com