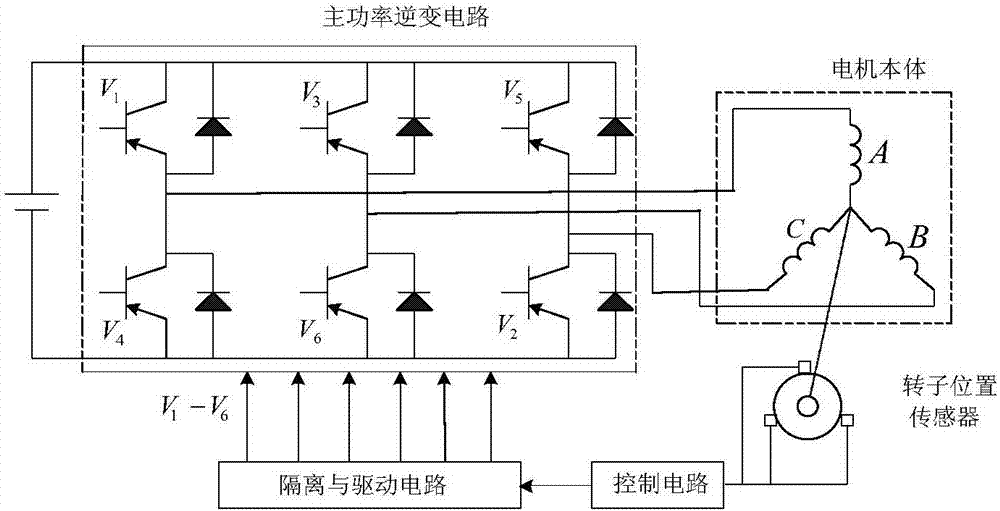

Brushless direct current motor sensorless commutation position detection commutation method

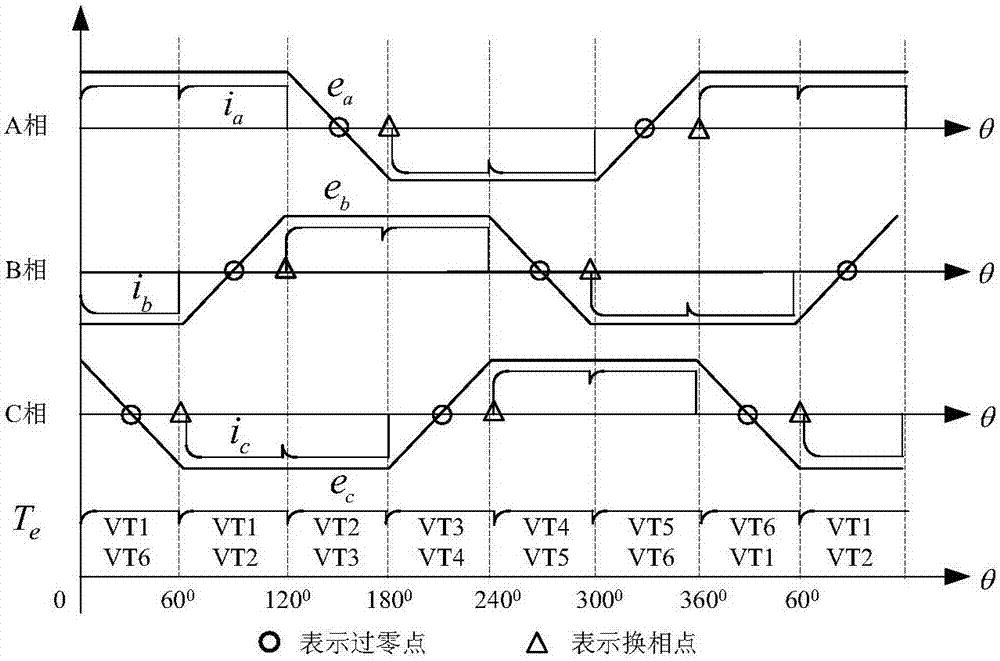

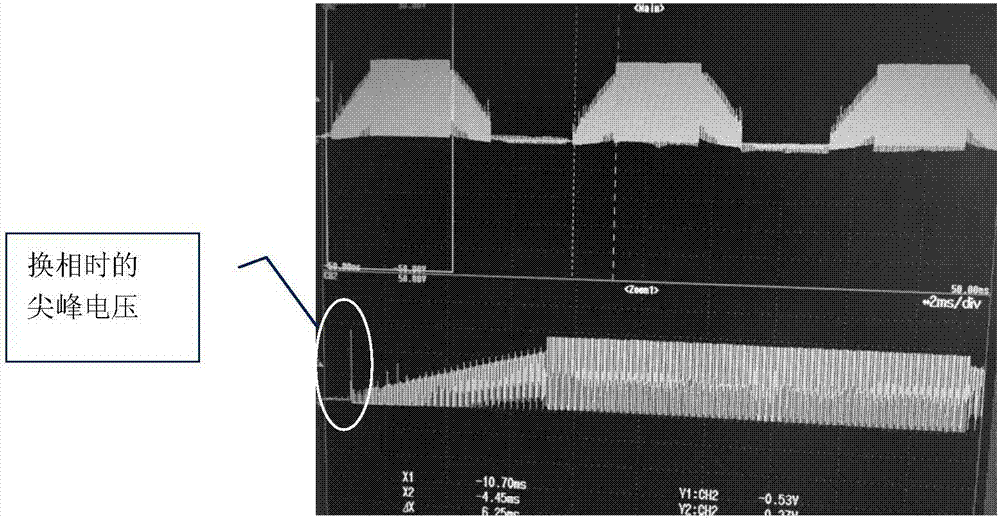

A brush DC motor and sensor technology, which is applied in the field of position sensorless brushless DC motor control, can solve the problems of increased current fluctuation, reduced system efficiency, motor vibration, etc., and achieves the effect of accurate phase commutation and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0027] In the three-phase six-state brushless DC motor bus current detection circuit, the three-phase voltage of the motor is sent to the AD port of the DSP for detection after being filtered and amplified by the voltage sensor. It is especially emphasized that the filtering here only filters out the high-frequency clutter above the chopping frequency.

[0028] The control cycle of the control system software is 25uS (40kHz), the PWM chopping frequency is 15kHz, and the DSP uses TMS320F28335 of TI Company.

[0029] The specific implementation of zero-crossing sampling and commutation algorithm is according to Figure 4 Proceed as shown in the flowchart.

[0030] Step 1: In the initialization of the system control software, initialize the ADC module; there are two PWM modules, A and B, in the TMS320F28335 control chip, and set the A and B PWMs to synchronous mode; set the B PWM comparison event As an ADC interrupt trigger event: ADCTRL2.bit.EPWM_ENA_SEQ1=1.

[0031] Step 2: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com