Method for calibrating and controlling parameters of motor

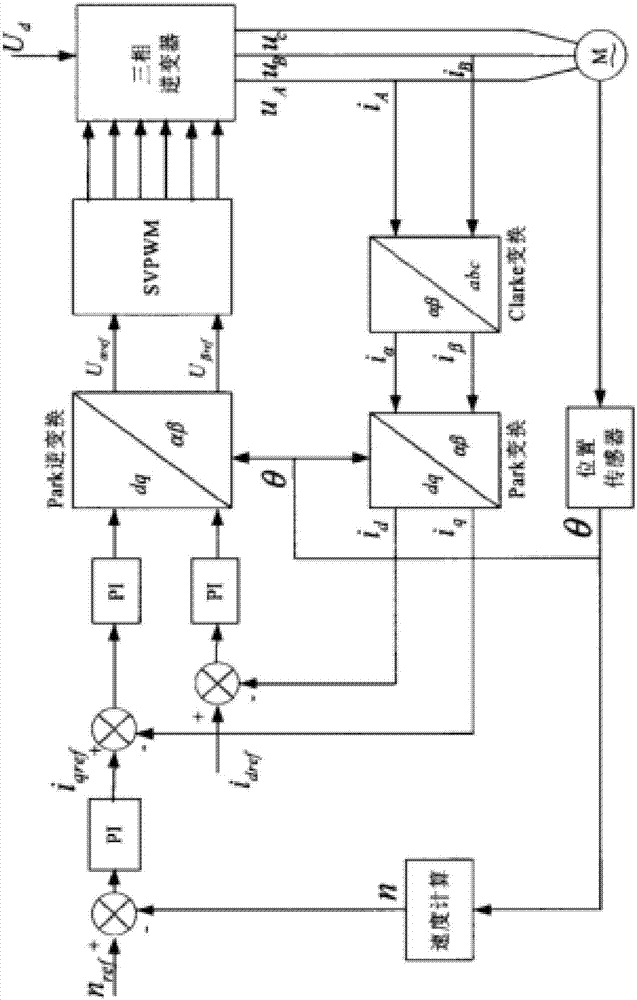

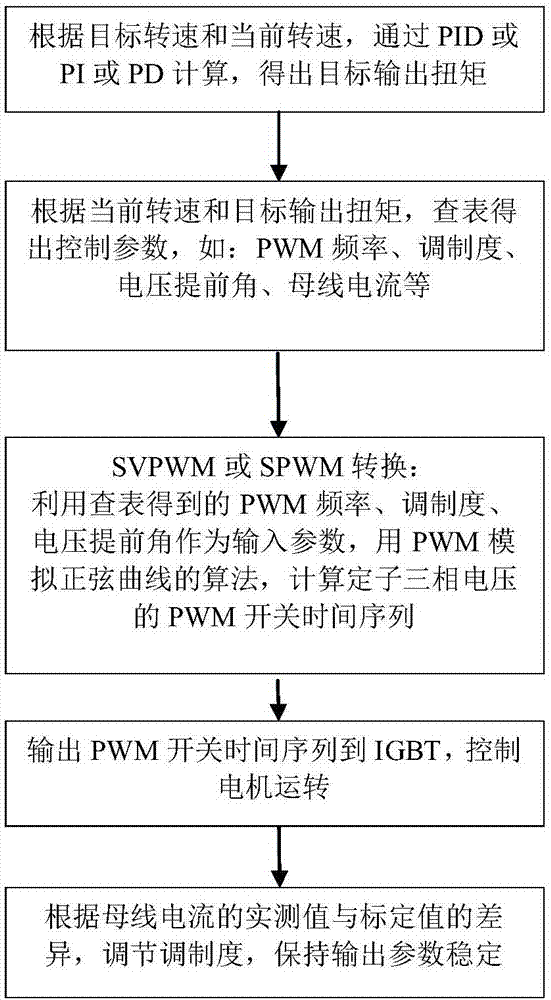

A control method and parameter calibration technology, applied in the estimation/correction of motor parameters, etc., can solve the problems of efficient control, complex calculation process, mathematical model restriction, etc., to achieve efficient and precise control, simplified mathematical model, accurate and efficient control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

[0024] Described method example by bench test:

[0025] Composition: The target motor is connected to the dynamometer through the torque sensor (the dynamometer has at least the function of controlling the speed), the dynamometer is used to control the motor output shaft to run stably at the set speed, and the torque sensor is used to measure the output of the target motor torque.

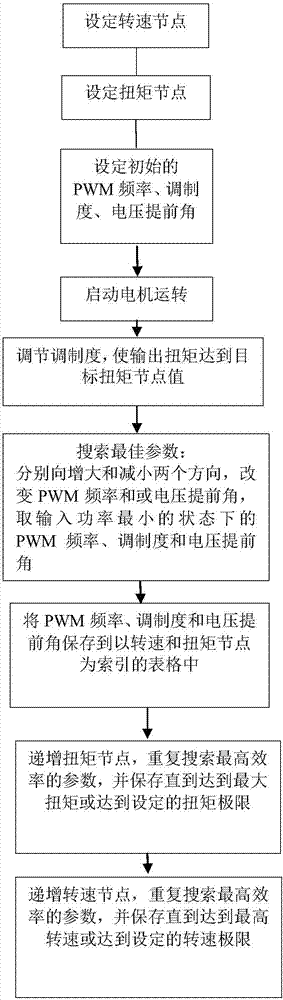

[0026] Calibration steps (such as figure 2 ):

[0027] First set the speed of the dynamometer at a target value;

[0028] Set a minimum target torque;

[0029] Then, start the target motor through a set of initial control parameters;

[0030] Change the control parameters of the target motor one by one or at the same time, by comparing the input power, obtain the control parameters of the motor corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com