Extruding stamping die installing vehicle

A technology for stamping dies and installing vehicles, which is applied in the direction of hand-held tools and manufacturing tools, which can solve the problems of high coordination requirements, long mold installation time, and high labor intensity of workers, so as to avoid safety accidents, compact structure, shorten The effect of disassembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

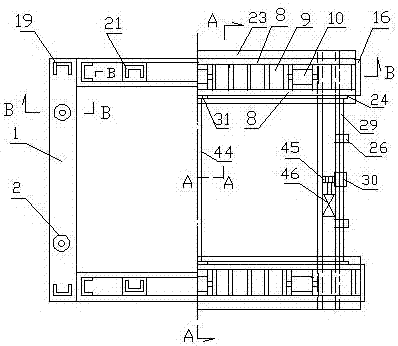

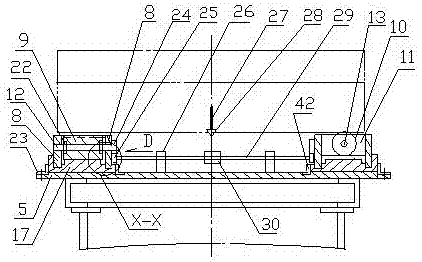

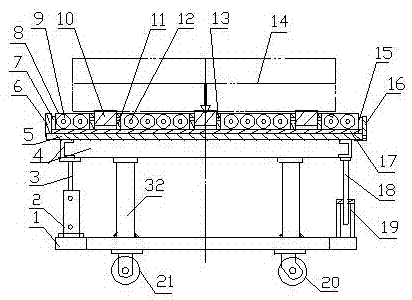

[0016] exist Figure 1 to Figure 8 Among them, the extrusion stamping die installation vehicle includes a bottom frame 1, a top frame 4, a base plate 5 and a supporting plate 17, and the bottom frame and the top frame are both square and made of channel steel or I-shaped steel, and the bottom frame and the top frame The four corners of the frame are respectively provided with support 19 and cylinder 2, and the lower part of the bottom frame is provided with a universal wheel 20 and a directional wheel 21, and the support is provided with an adjusting screw 18, and the upper end of the adjusting screw is fixedly connected with the top frame. The lower end of the support is fixed on the chassis. The cylinder is fixed on the bottom frame, the upper end of the piston rod 3 in the cylinder is fixedly connected with the top frame, and a supporting rod 32 is arranged between the bottom frame and the top frame. The function of the supporting rod is to prevent the piston rod and the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com