Automatic label cutting and delivering device for full automatic pillow case machine

A fully automatic and standard-feeding technology, applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the problems of low product accuracy, unsightly appearance, low production efficiency, etc., and achieve the effect of convenient use and labor saving, and the overall structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

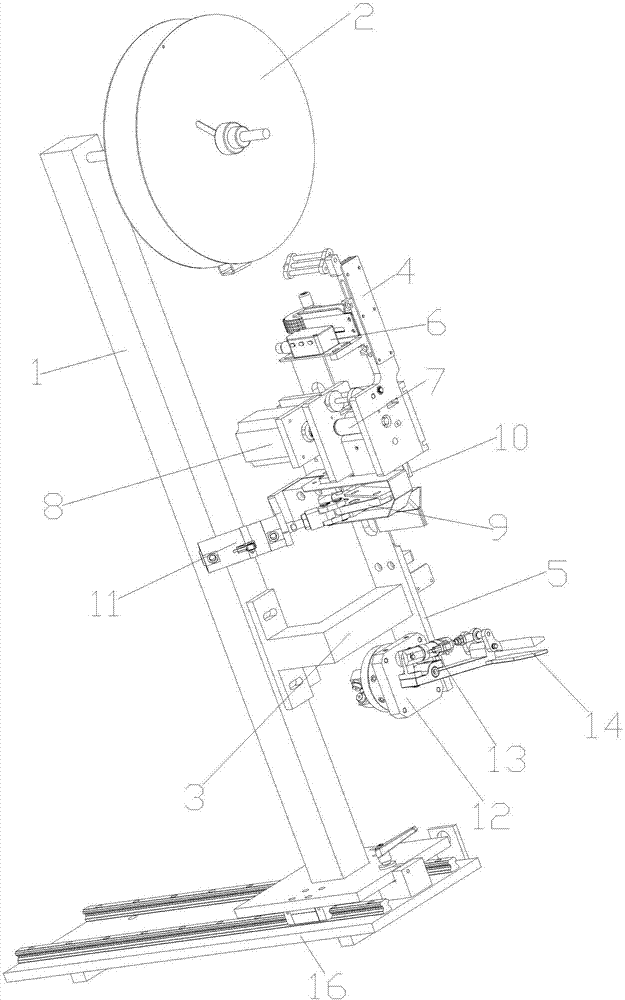

[0011] as attached figure 1 The shown automatic standard cutting and standard delivery device for a fully automatic pillowcase machine of the present invention includes a standard delivery base plate 16, a standard delivery support 1, a standard delivery tray 2, a bearing block 3, a first support 4, a second Support 5, color mark device 6, mark sending wheel 7, mark sending power motor 8, first cutter 9, second cutter 10, linkage mechanism, first cutter power cylinder 11, mark sending rotary cylinder 12, Standard clamp cylinder 13 and standard clamp 14; The standard delivery base plate 16 is provided with a slidable standard delivery support 1; The upper end of the standard delivery support 1 is provided with a standard delivery tray 2; Block 3; the side of the bearing block 3 is provided with a second support 5 and a first support 4...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap