Skid-mounted well repair operation flushing fluid recycling device and method

A skid-mounted technology for well flushing fluid, which is applied in the field of skid-mounted well flushing fluid recycling devices for well workover operations, can solve the problems of inability to deal with sand, oil content, high equipment cost, etc., and meet the water quality requirements Low, improve the utilization rate, improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

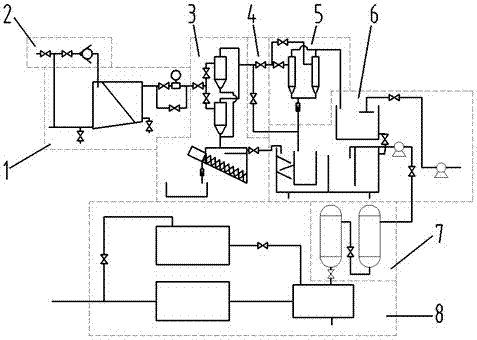

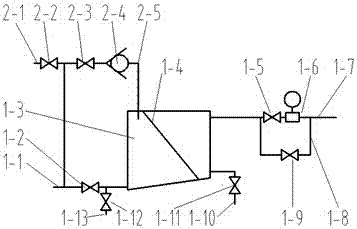

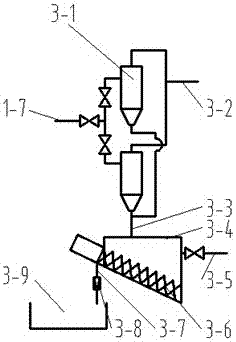

[0040] according to figure 1 , a skid-mounted well cleaning fluid recycling device for well workover operations, including a pretreatment process 1, a sand removal process 3, an oil removal process 5, a settling tank 6, a filtration process 7, a well entry process 8, and a well fluid detection process 2, Degreasing goes beyond process 4. Well fluid detection process 2 is connected to pretreatment process 1. The pretreatment process 1 is connected with the desanding process 3. The oil removal overflow main line 3-6 of the desanding process 3 is connected to the degreasing beyond process 4, and the water overflow line 3-5 of the sand settling box 3-4 directly enters the grit chamber 6-2 of the settling tank process 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com