Noise-reducing method for electric fan based on blade modification and improved blade structure of electric fan

A technology of blade structure and electric fan, which is applied to components of pumping devices for elastic fluids, electrical digital data processing, instruments, etc., can solve the problems of unsuitable electric fan blades, delay flow separation, reduce vortex The effect of magnitude and aerodynamic interference reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

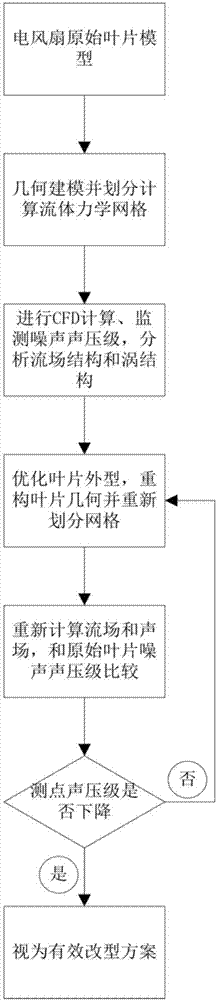

Method used

Image

Examples

Embodiment

[0043] The present invention has tried more than a dozen blade modification schemes, such as changing the blade camber and twist angle, adding methods such as airfoil design, etc.; tried modeling methods such as multi-reference system algorithm, unsteady slip grid algorithm, and studied Selection of mechanical turbulence models, including SA model, k-epsilon model. The far-field noise is calculated based on the FW-H sound comparison technology. Through the analysis of the flow field and sound field data, it is found that the noise can be reduced by 3dB through blade modification while maintaining the air volume, which has a significant effect. Table 1 is a comparison of the noise reduction effects of the three modification methods.

[0044] Table 1 Comparison of the respective effects of the three schemes

[0045] Modification method

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com