An aluminum-magnesium alloy lift-mounted cable bridge

A cable tray, aluminum-magnesium alloy technology, applied in electrical components and other directions, can solve the problems of increasing the workload of maintenance personnel, difficult installation of the top tray, troublesome installation of the cable tray, etc. Work load, effect of less safety accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

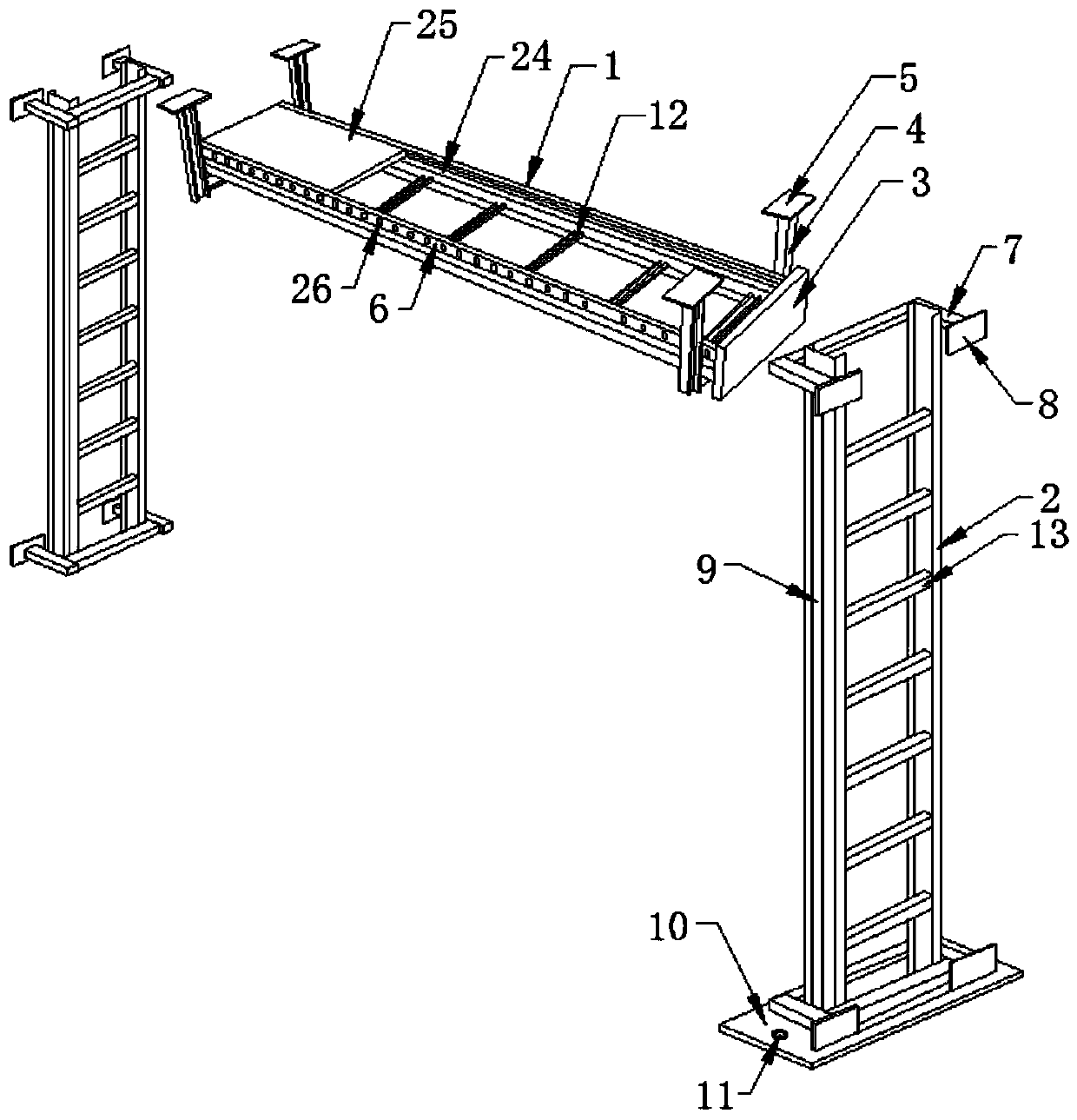

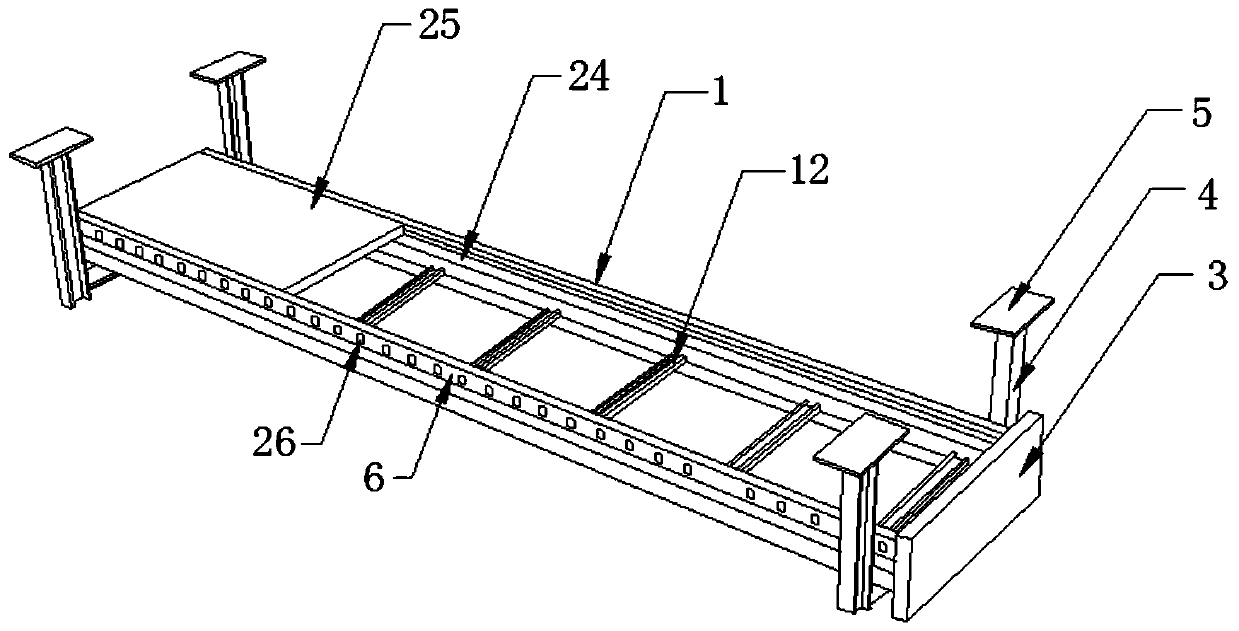

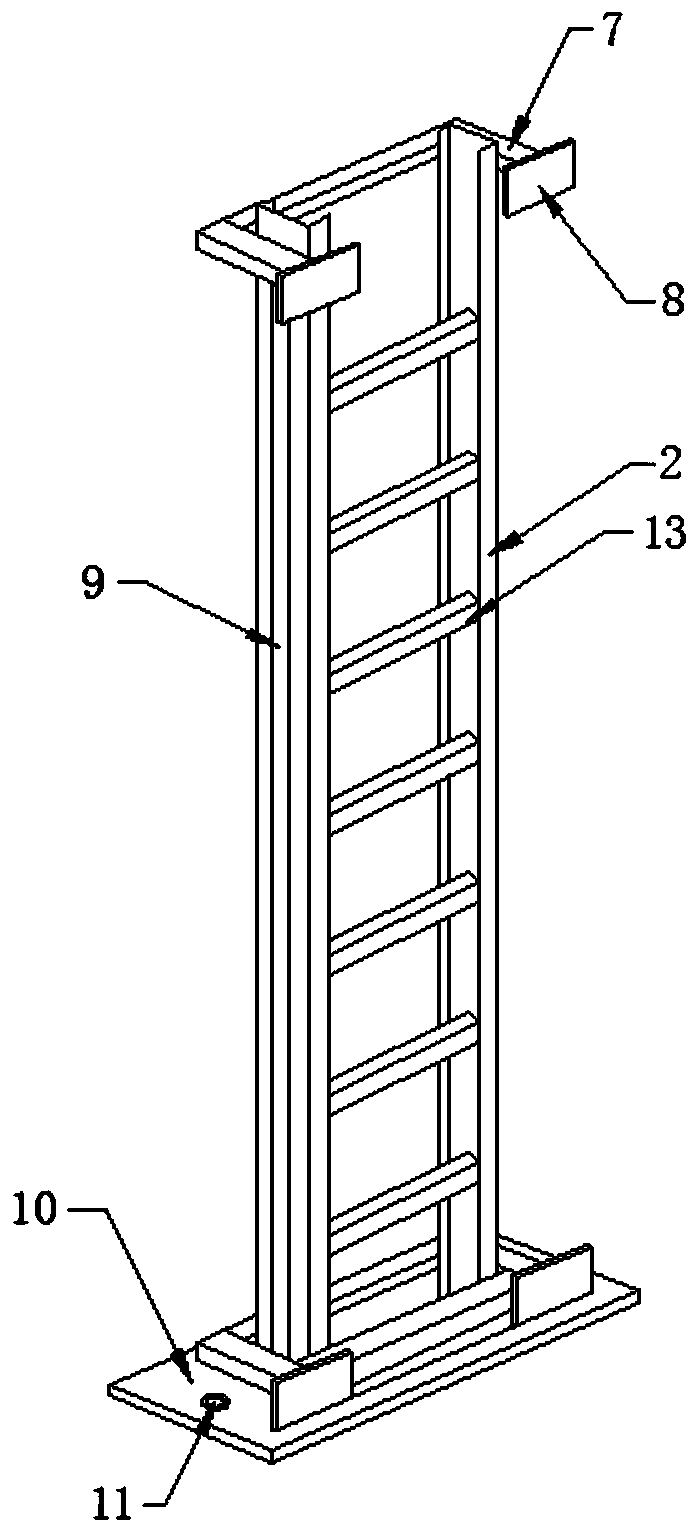

[0025] like Figure 1-4 As shown, the present invention provides an aluminum-magnesium alloy lifting cable tray, including a cable tray 1, a connecting support frame 2 is installed at both ends of the cable tray 1, and a sliding connector 3 is installed at both ends of the cable tray 1. Both ends of one side of the connector 3 are provided with a slide rail connecting block 14, one side of the slide rail connecting block 14 is provided with a connecting slider 19, the inner side of the connecting slider 19 is provided with a positioning screw hole 22, and the inner side of the cable tray 1 is provided with a There is a beam bridge 6, the inner side of the beam bridge 6 is provided with a number of cable support beams 12, the beam bridge 6 is provided with a number of through holes 26, the cable bridge 1 is connected with the connecting support frame 2 through the sliding connector 3, and the connecting support frame 2 Support frame slide rails 9 are arranged on both sides, a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com