Electric quantity equalization method of power battery, battery management system and dynamic electric vehicle

A technology of battery management system and power battery, which is applied in the direction of charge equalization circuit, secondary battery charging/discharging, battery circuit device, etc., and can solve problems such as unproposed solutions, uncertain contribution ratio, incorrect charging or non-discharging of batteries, etc. , to achieve the effect of improving the balance efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

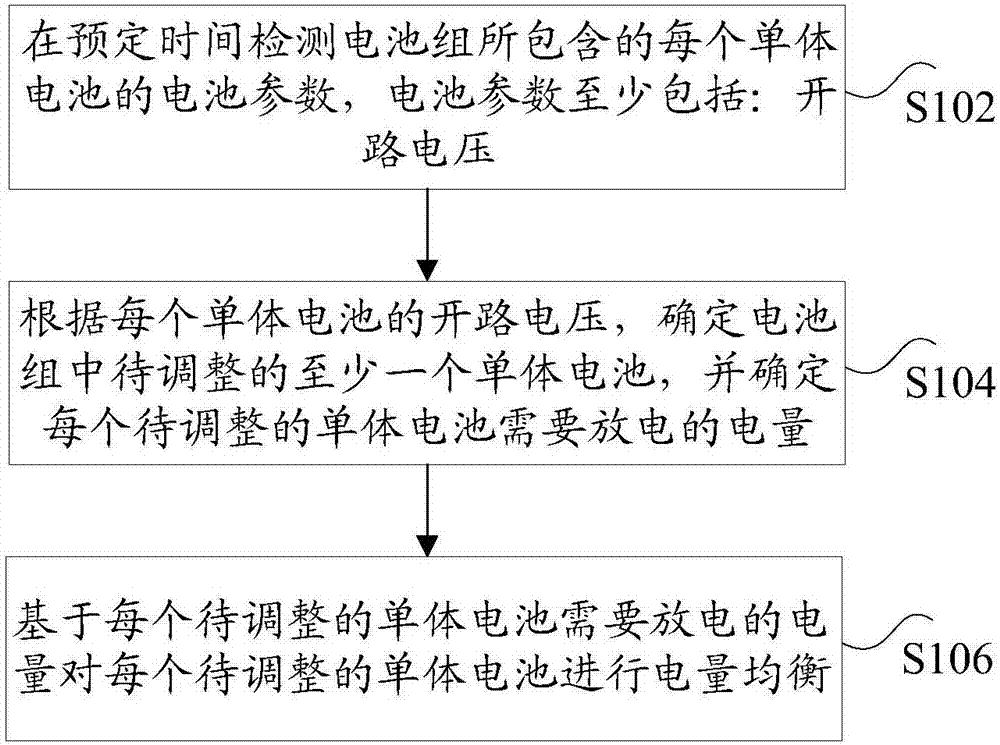

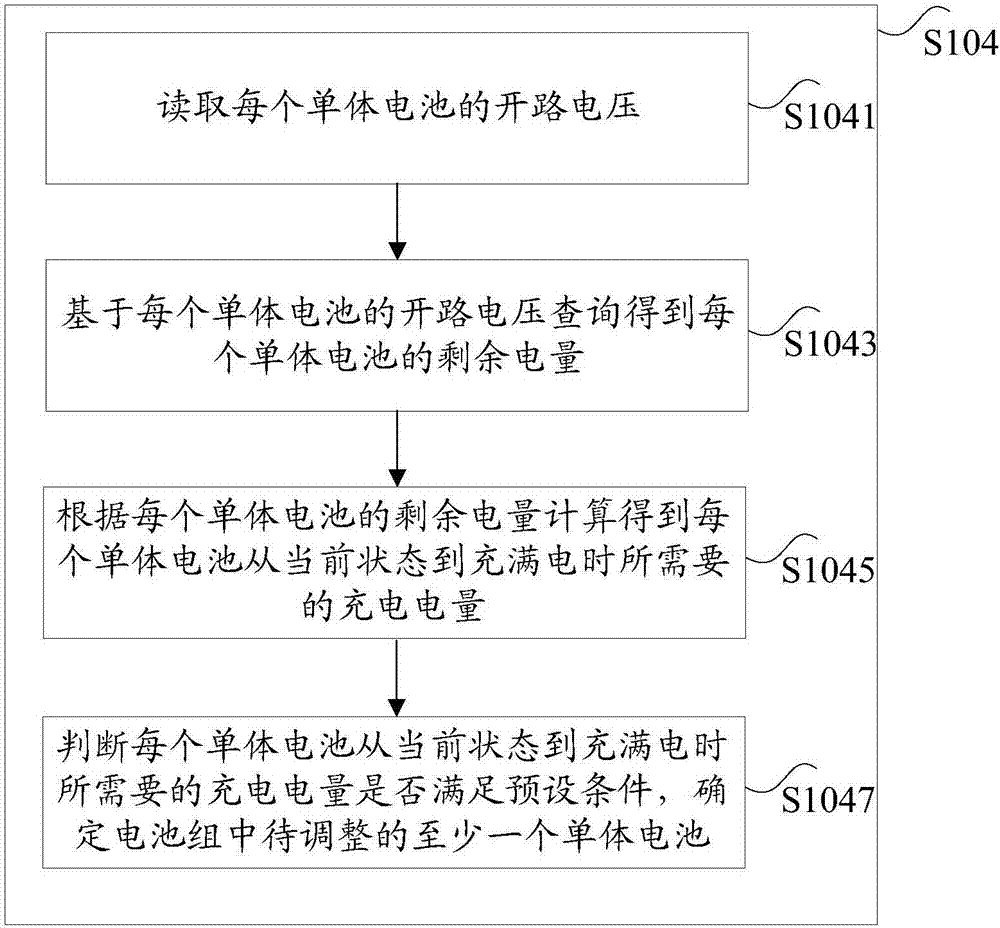

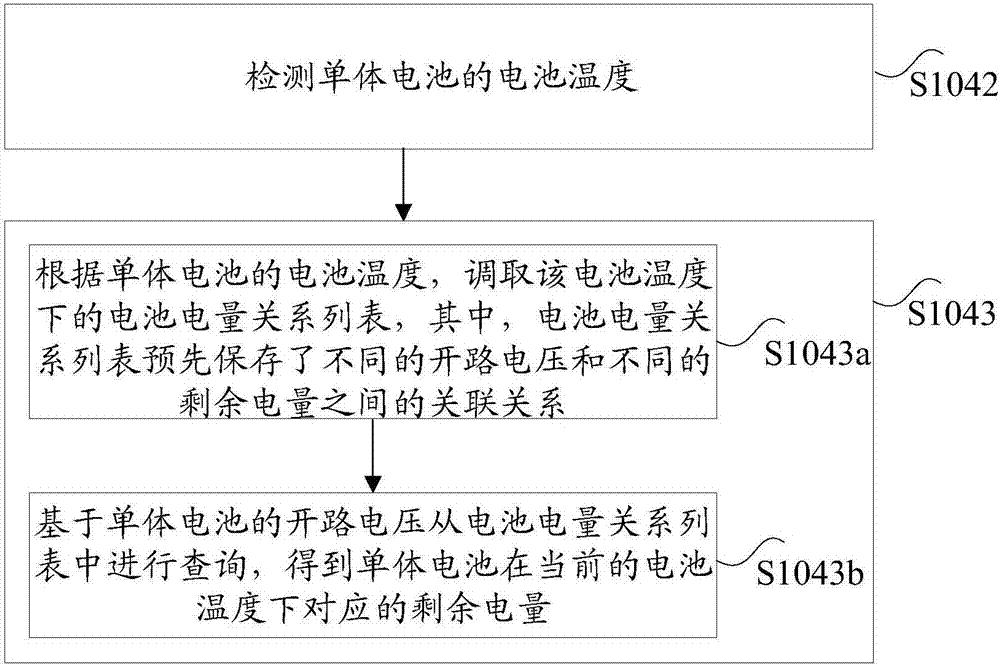

[0049] According to an embodiment of the present invention, an embodiment of a power balance method for a power battery is provided, figure 1 It is a flow chart of a power balance method for a power battery according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0050] Step S102 , detecting battery parameters of each single battery included in the battery pack at a predetermined time, the battery parameters at least including: open circuit voltage.

[0051] In the above steps, the above-mentioned battery pack can be a power battery pack installed on an electric car, and the above-mentioned predetermined time can be any time when the battery is in a no-current state for about 2 hours (with no load current and terminal voltage change rate lower than a certain value), that is, after the electric vehicle has been left for a period of time, for example, after the driver parks the vehicle at night for more than 2 ho...

Embodiment 2

[0104] According to an embodiment of the present invention, an embodiment of a battery management system is also provided. The power balance method for power batteries in Embodiment 1 of the present invention can be implemented in the battery management system in Embodiment 2 of the present invention.

[0105] Figure 7 is a schematic diagram of a battery management system according to an embodiment of the present invention, such as Figure 7 As shown, the battery management system includes: a first detection module 702 , a first determination module 704 and a first processing module 706 .

[0106] Among them, the first detection module 702 is used to detect the battery parameters of each single battery included in the battery pack at a predetermined time, and the battery parameters at least include: open circuit voltage; the first determination module 704 is used to open circuit voltage, determine at least one single cell to be adjusted in the battery pack, and determine th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com