Lawn mower

A lawn mower and lawn mower technology, applied in harvesters, presses, cutters, etc., can solve problems such as unfavorable staff and customers, reduce lawn mowing efficiency, manpower and economic waste, and save manpower. and financial resources, full-featured, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

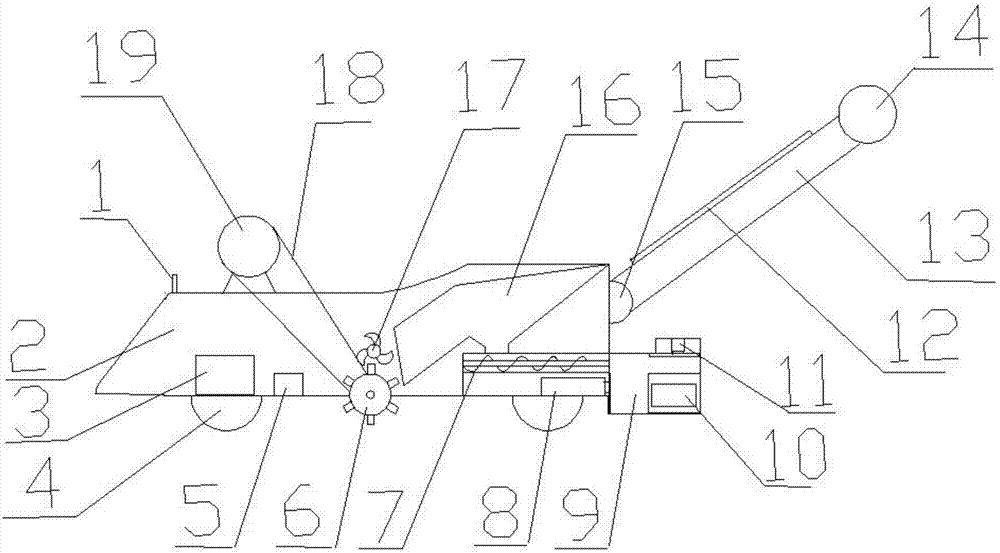

[0013] figure 1 Show the specific embodiment of the present invention: a kind of lawnmower, comprise hand push rod 13, car body 2 and grass collecting box 9, described hand push rod 13 is arranged on the outer side wall of car body 2 rear end, and described car body 2 The inner cavity is provided with a storage battery 3, an engine 19, a mowing knife 6, a grass collecting fan 17, a grass collecting pipeline 16 and a screw conveyor 7, and the middle of the bottom of the car body 2 is provided with a feeding port, and the grass mowing knife 6 Located at the feed inlet, the engine 19 is connected to the mowing knife 6 through a belt 18, the grass collection pipe 16 is located at the top of the inner cavity of the car body 2, and the grass collection fan 17 is arranged at the entrance of the grass collection pipe 16, located at Above the mowing knife 6, a screw conveyor 7 is provided below the grass outlet of the grass-collecting pipeline 16, and the grass outlet of the grass-coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com