Sleeve head positioning and drilling mechanism

A technology of drilling mechanism and positioning mechanism, which is applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc. Low production efficiency and other problems, to achieve the effect of simple structure, conducive to popularization and use, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

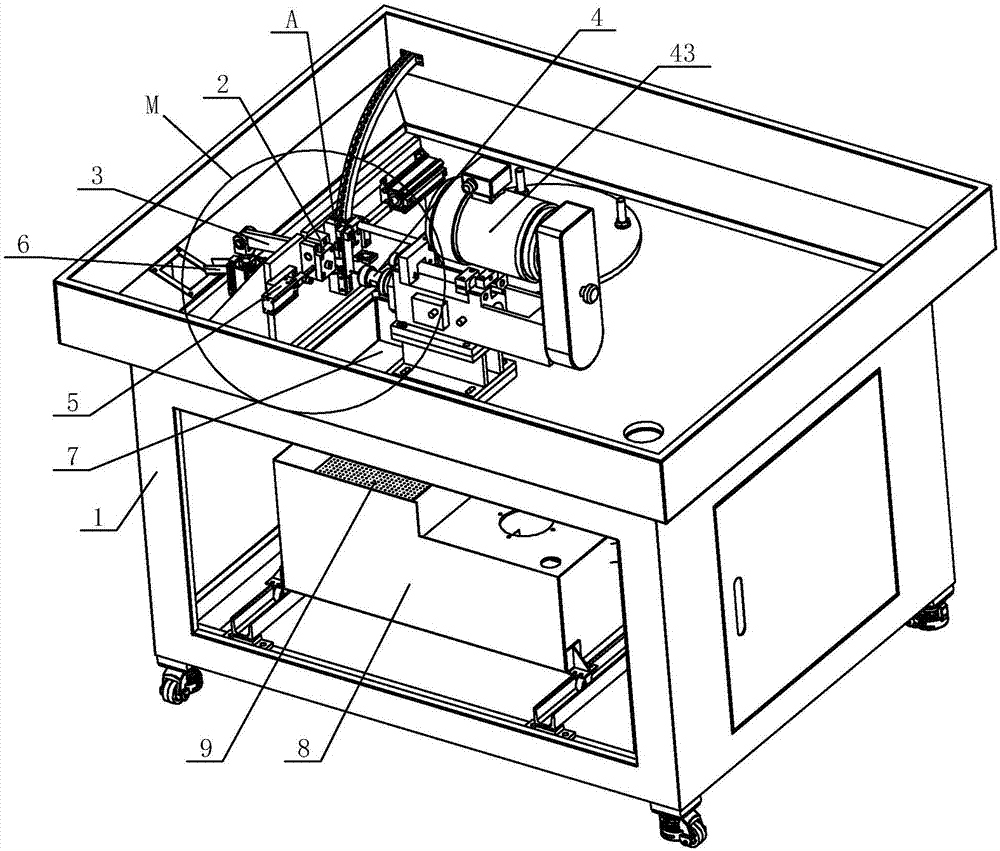

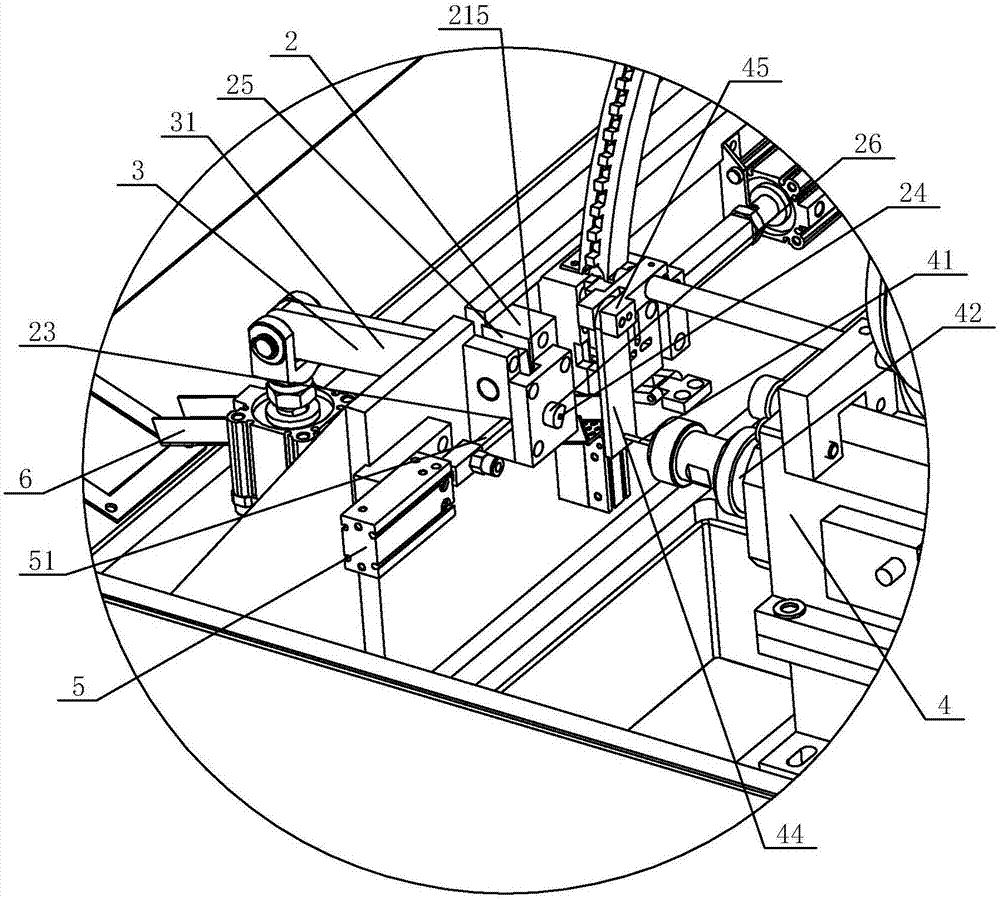

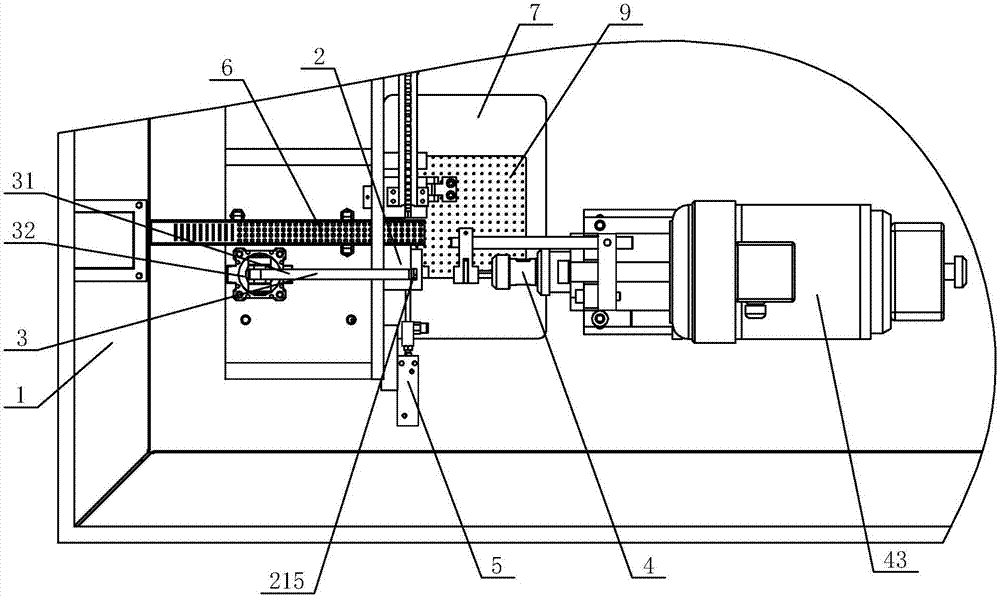

[0022] Such as Figure 1-5 Shown is a specific embodiment of the sleeve head positioning drilling mechanism of the present invention. This embodiment includes a frame 1 and a sleeve head limiting tool 2 installed on the frame 1, a positioning mechanism 3, a drilling mechanism 4 and a pushing mechanism 5, and the sleeve head limiting tool 2 is provided with an accommodating sleeve The limit cavity 21 of the head, the limit cavity 21 is provided with a material inlet 22 on one side in the length direction, and the opposite side of the material inlet 22 is provided with a top material hole 23, and the limit cavity 21 is set on one side in the width direction. Boring 24, the top of spacer cavity 21 offers gap 25; Drilling mechanism 4 is oppositely set with going into drilling hole 24, and drilling mechanism 4 comprises the drill bit 41 that can e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com