Special stack mold injection molding machine for template opposite-opening mold moving middle injection

An injection molding machine and template technology, which is applied in the field of special injection molding machines for stack molds, can solve the problems of increasing manufacturing difficulty, low work efficiency, affecting action time, etc., and achieves the effects of improving action stability, improving work efficiency, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

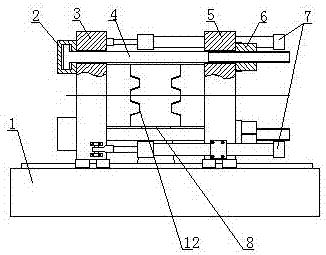

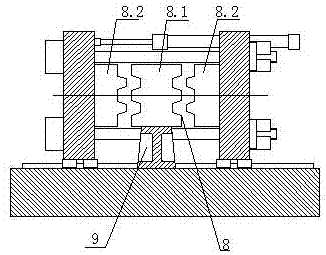

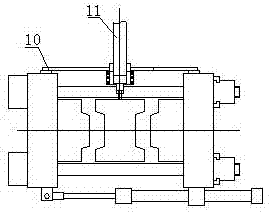

[0036] Such as figure 1 , figure 2 As shown in the figure, a special injection molding machine for stack molds with templates separated and moved in the middle of the mold includes a frame 1 and a mold 8. It also includes a pressurized oil cylinder group, a pressurized template 3, a brake template 5, a brake mechanism 6, Die transfer cylinder 7, mold base 9 and injection mechanism 11;

[0037] The booster template 3 and the brake template 5 are vertically installed on the frame 1, the booster cylinder group is composed of a plurality of booster cylinders 2, the booster cylinder 2 is fixed on the booster template 3, and the brake mechanism 6 is fixed on the brake On the template 5, the piston rod 4 of the booster cylinder 2 extends throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com