Glass cutting machine

A glass cutting and cutting machine technology, used in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as high experience requirements, glass cannot be broken, and glass is easily broken, so as to improve cutting quality and reduce The influence of cutting experience and the effect of improving the success rate of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

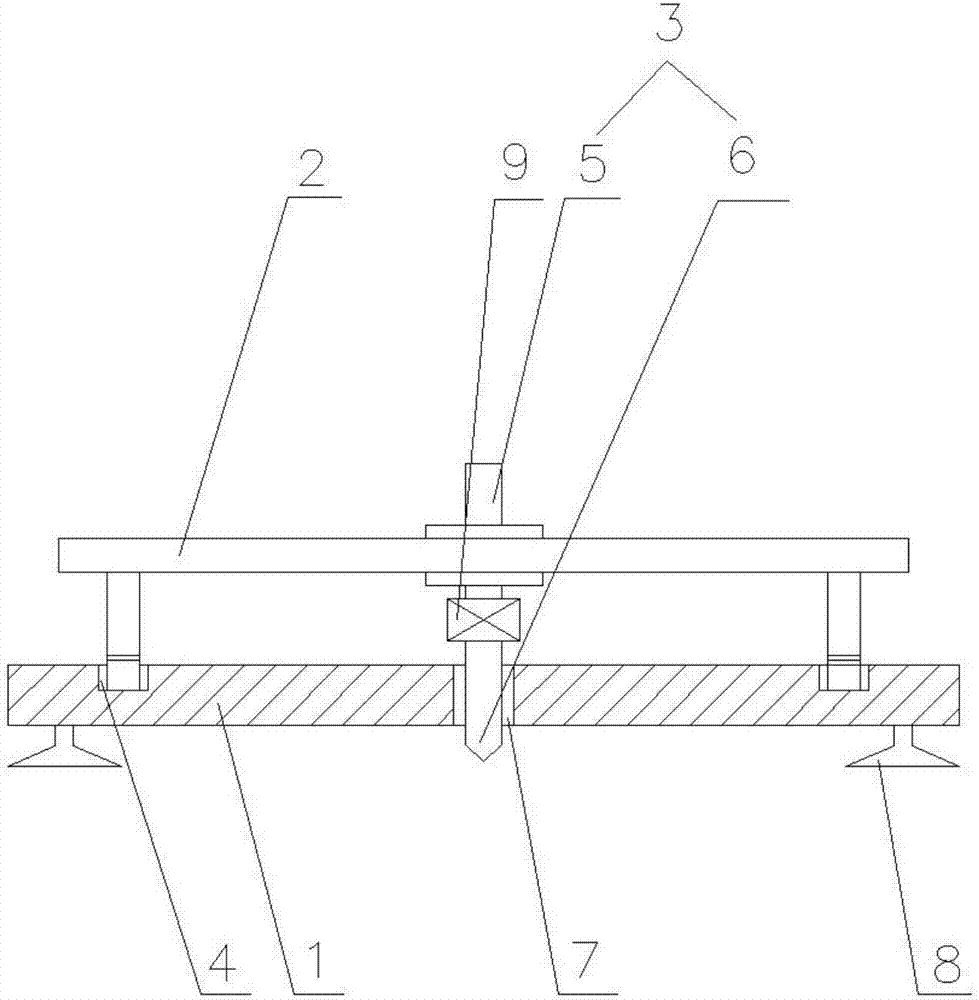

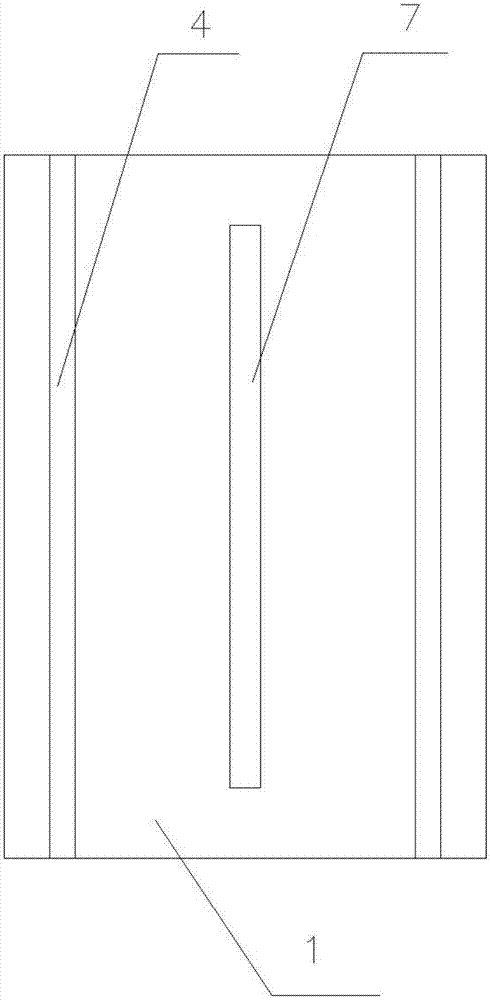

[0024] As shown in the figure, a glass cutting machine includes a knife seat 1 , a knife holder 2 and a glass cutting knife 3 . The upper surface of the knife holder 1 is provided with two parallel slide rails 4, the bottom surface of the knife holder 2 is provided with pulleys, the pulleys are slidably installed on the parallel slide rails 4, the knife holder 2 slides along the direction of the slide rails 4, and can only slide along the Sliding in a straight line reduces the error rate when cutting glass. The pulley and slide rail 4 are one of the sliding methods, and can also be other mechanical structures that make the knife holder 2 slide linearly along the knife holder 1 . An installation through hole for installing the glass cutting knife 3 is provided on the knife holder 2, and an external thread is provided on the handle 5 of the glass cutting knife 3, and the glass cutting knife 3 passes through the installation through hole and is fixed by two nuts On the knife hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com