A kind of high temperature anti-decarburization coating and preparation method thereof

An anti-decarburization coating and high temperature technology is applied in the field of refractory materials to achieve the effects of reducing environmental pollution, being beneficial to environmental protection and having a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

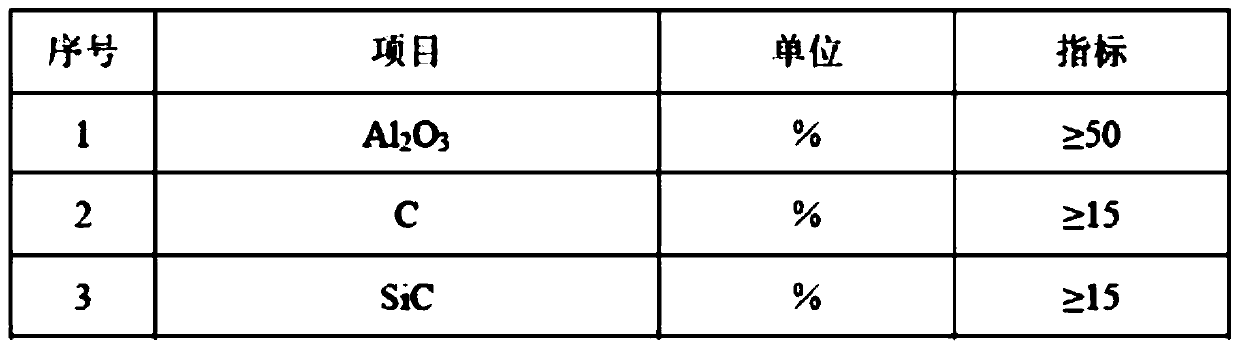

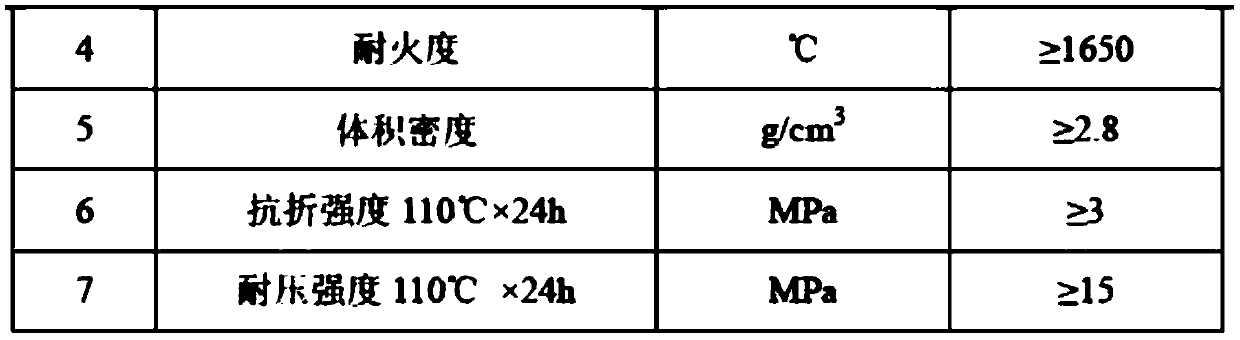

Embodiment 1

[0036] A high-temperature anti-decarburization coating, which is different from Example 1 in that: the coating is composed of two components A and B, and the weight percentages of the two components A and B are respectively 60% And 40%; the weight percentage composition of the A component is: high alumina bauxite powder 33%, graphite 25%, silicon carbide 15%, zirconium corundum powder 3%, Al2O3 ultrafine powder 17% and silica alumina 7%; The weight percentage composition of the B component is: 20% suspending agent and 80% binder. The rest is the same as in Example 1.

[0037] The binder is phenolic resin.

[0038] The particle size of the high alumina bauxite powder is -300 mesh; in the high alumina bauxite powder, Al 2 O 3 The mass percentage content of ≥80%, Fe 2 O 3 The mass percentage content of the bauxite powder is less than or equal to 2%, and the bulk density of the high bauxite powder is more than or equal to 2.9g / cm3.

[0039] The graphite used is T890 graphite produced b...

Embodiment 2

[0047] A high-temperature anti-decarburization coating, which is different from Example 1 in that: the coating is composed of two components A and B, and the weight percentages of the two components A and B are respectively 70% And 30%; the weight percentage composition of the A component is: high alumina bauxite powder 26%, graphite 15%, silicon carbide 35%, zirconium corundum powder 7%, Al 2 O 3 13% ultrafine powder and 4% silica-alumina glue; the weight percentage composition of the B component is: 30% suspension agent and 70% binder. The rest is the same as in Example 1.

Embodiment 3

[0049] A high-temperature anti-decarburization coating, which is different from Example 1 in that the coating is composed of two components A and B, and the weight percentages of the two components A and B are respectively 50% And 50%; the weight percentage composition of the A component is: high alumina bauxite powder 30%, graphite 20%, silicon carbide 25%, zirconium corundum powder 5%, Al 2 O 3 15% ultrafine powder and 5% silica-alumina glue; the weight percentage composition of the B component is: 25% suspending agent and 75% binder. The rest is the same as in Example 1.

[0050] When the high-temperature anti-decarburization coating of the present invention is applied, it is found that it has the advantages of strong oxidation resistance, heat resistance, good thermal shock stability, etc.; after using the high-temperature anti-decarburization coating of the present invention, a protection is formed on the surface of steel Film, reduce the depth of the decarburization layer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com