Washing machine and inner barrel structure of washing machine

A washing machine and inner tub technology, applied in the field of washing machines, can solve the problems of wasting resources and energy, increasing the volume of the washing machine, and the effect needs to be improved, and achieves the effect of saving water, shortening the cycle period, and having a good washing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

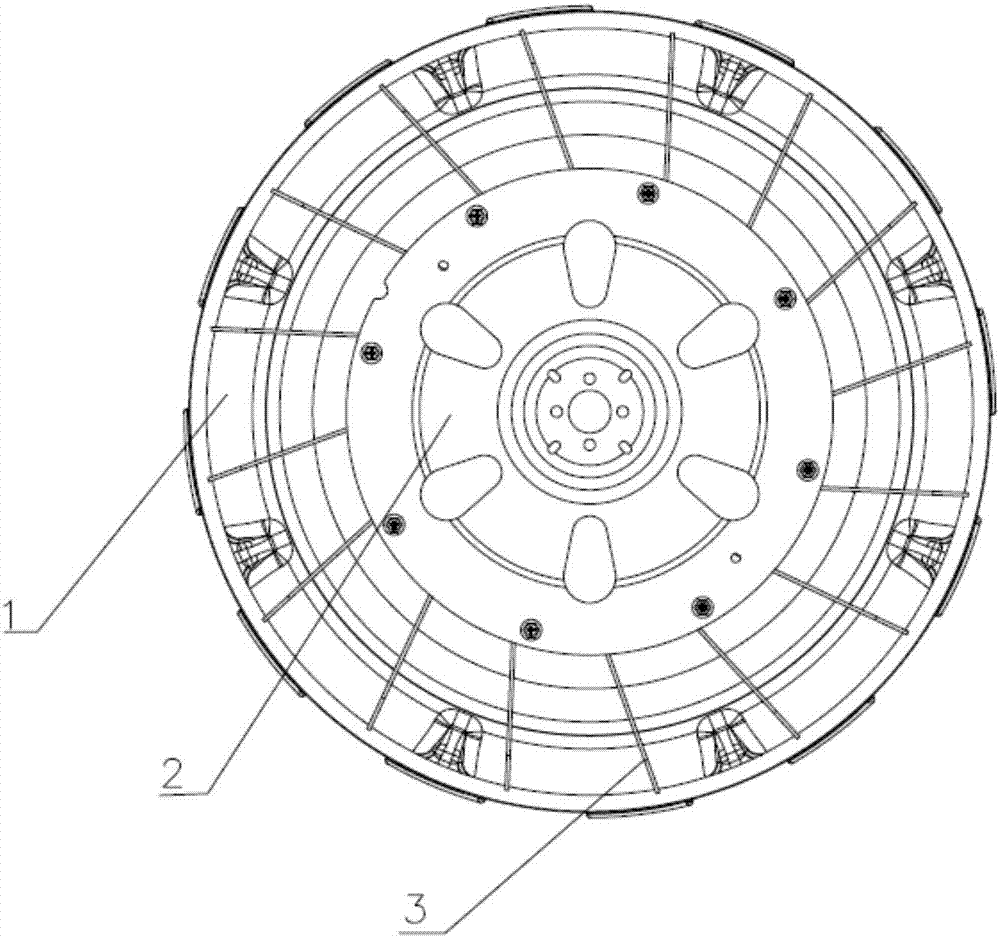

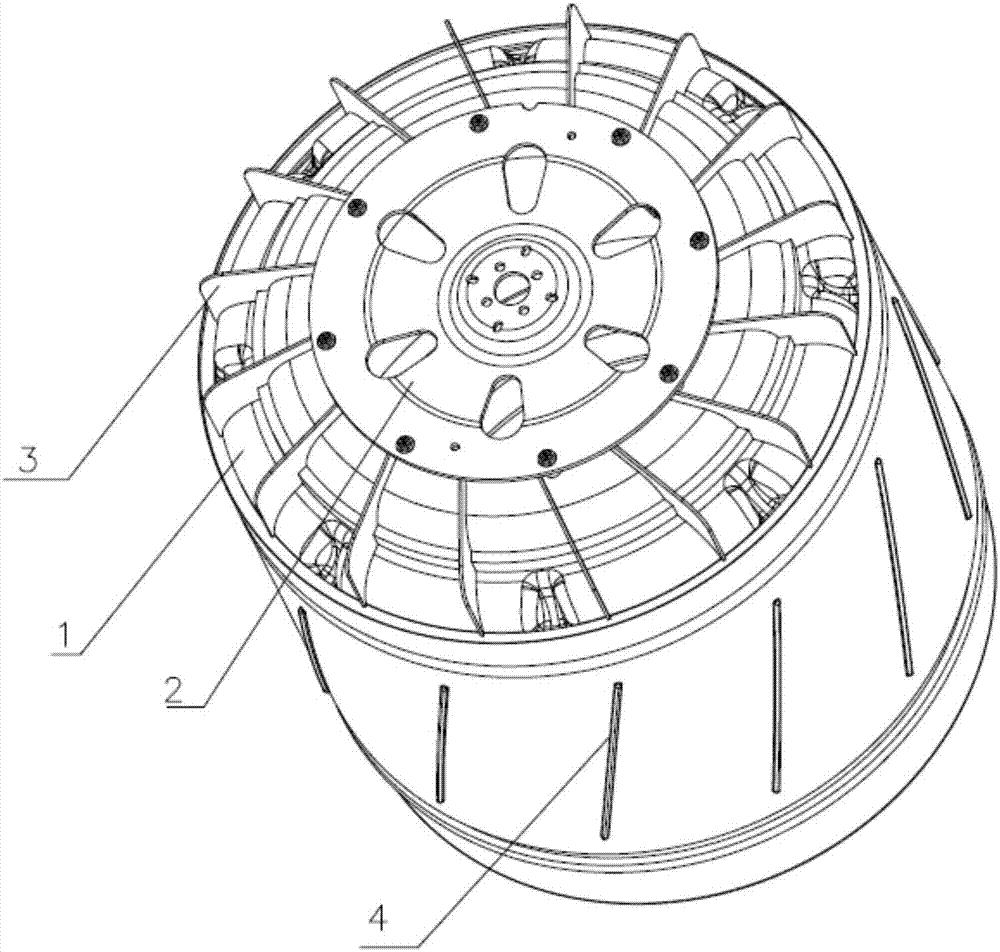

[0041] An inner barrel structure of a washing machine, the outer bottom of the inner barrel is provided with a mounting flange 2, and the area between the outer periphery of the mounting flange 2 and the outer periphery of the outer bottom 1 of the inner barrel is provided with a protruding water-repellent leaf 3, and the water-repellent leaf 3. The angle between the end of the water-repelling leaf 3 close to the outer periphery of the outer bottom 1 of the inner bucket and the radial straight line at the center of the outer bottom 1 of the inner bucket is an acute angle, so that the water flow can be lifted up into the outer bucket cover and sprayed to the inner bucket. middle.

[0042] The included angles between each water-repellent leaf 3 and the radial straight line connecting the end of the water-repellent leaf 3 close to the outer periphery of the inner bucket outer bottom 1 and the center of the inner bucket outer bottom 1 are equal angles, or are respectively unequal a...

Embodiment 2

[0064] An inner tub structure of a washing machine, the outer bottom of the inner tub is provided with a mounting flange 2, and in the area between the outer edge of the mounting flange 2 and the largest outer diameter portion of the outer bottom 1 of the inner tub, there are multiple protrusions protruding from the surface of the outer bottom 1 of the inner tub The water-repelling leaf 3, the angle between the water-repelling leaf 3 and the radial straight line passing through the end of the water-repelling leaf 3 near the maximum outer diameter portion of the inner bucket outer bottom 1 and the center of the inner bucket outer bottom 1 is an acute angle.

[0065] The included angles between each water-repellent leaf 3 and the radial straight line passing through the end of the water-repellent leaf 3 close to the largest outer diameter portion of the inner bucket outer bottom 1 and the center of the inner bucket outer bottom 1 are equal angles, or are respectively unequal angle...

Embodiment 3

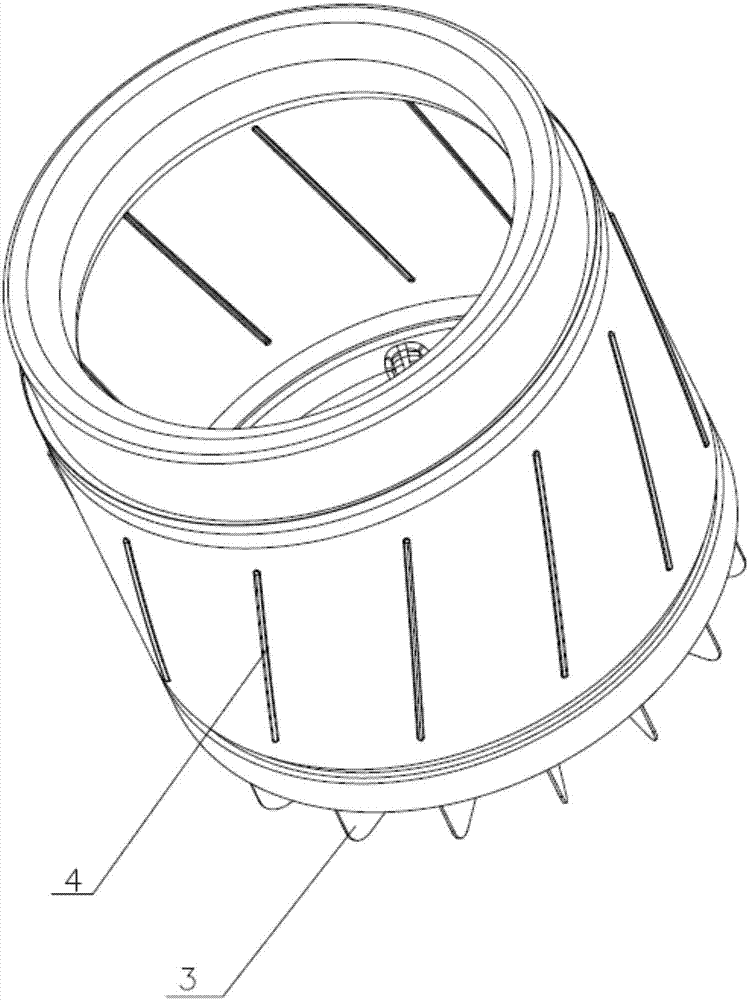

[0086] The difference between this embodiment and Embodiment 1 is that the arrangement of the water-repellent leaves 3 provided on the outer bottom of the inner tub of the washing machine is different. The included angle between the end of the water leaf 3 close to the maximum outer diameter of the outer bottom 1 of the inner bucket and the radial straight line at the center of the outer bottom 1 of the inner bucket is A m , m is a natural number greater than zero, representing the group ordinal number of water-repellent leaf 3, when m takes different values, A m The angle values are different.

[0087] For example, three groups of water-repelling leaves 3 are evenly arranged on the outer bottom of the inner bucket, and each water-repelling leaf 3 in the first group is connected to the end of each water-repelling leaf 3 close to the largest outer diameter of the inner bucket outer bottom 1 and the center of the inner bucket outer bottom 1. The included angles between the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com