Piston-type particle-damping energy-dissipation vibration-reduction railway ballast

A particle damping, piston-type technology, applied in the field of rail transit, can solve the problems of insufficient compaction of the subgrade in the transition section, difficult geological conditions, and easy settlement in the transition section, achieving large damping, reducing subgrade settlement, and improving power. Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

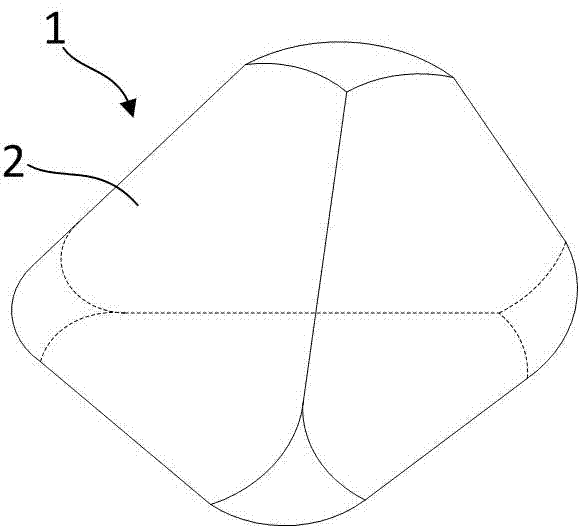

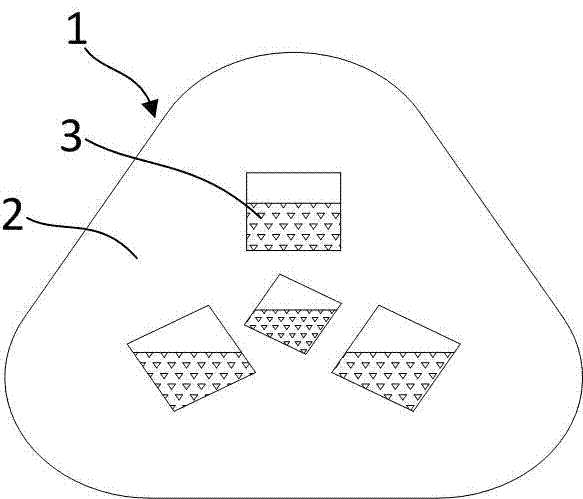

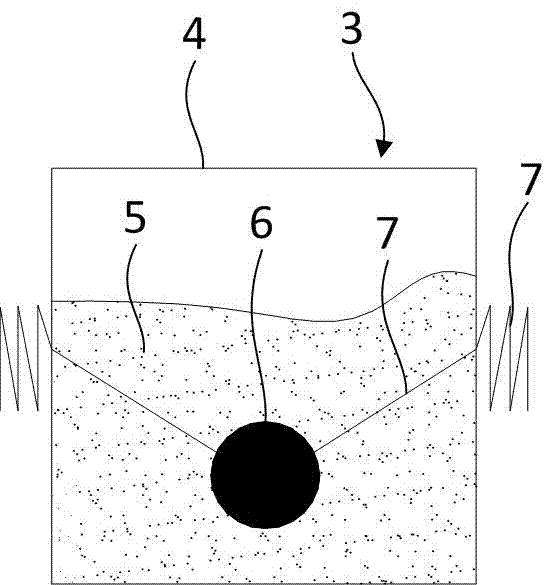

[0023] Example: such as figure 1 , 2 As shown, this embodiment specifically relates to a piston-type particle damping energy-dissipating vibration-damping ballast 1, which includes a concrete block 2 and a piston-type particle damping ballast embedded in the concrete block 2. Element 3.

[0024] like figure 1 , 2 As shown, the concrete block 2 of the present embodiment is a regular tetrahedron with a side length of 6 cm; in order to avoid the concrete breaking at the sharp corners of the concrete block 2 during use and thereby cause the hardening of the ballast, the concrete block 2 needs to be adjusted. The sharp corners are rounded; during the chamfering process, the concrete in the area 1cm away from the sharp corner of the concrete block 2 is rounded; the straight line length of each side of the concrete block after processing is 4cm; the concrete block 2 The volume ratio of cement and sand is 1:1; the cement used in concrete block 2 is Portland cement with a strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com