Profile steel outer arrangement and rear inserting type dual-row pile foundation pit supporting system and construction method thereof

A technology of foundation pit support and double-row piles, which is applied in foundation structure engineering, excavation, construction, etc., can solve problems such as prone to lateral collapse, achieve good support effect, prevent lateral bulging, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

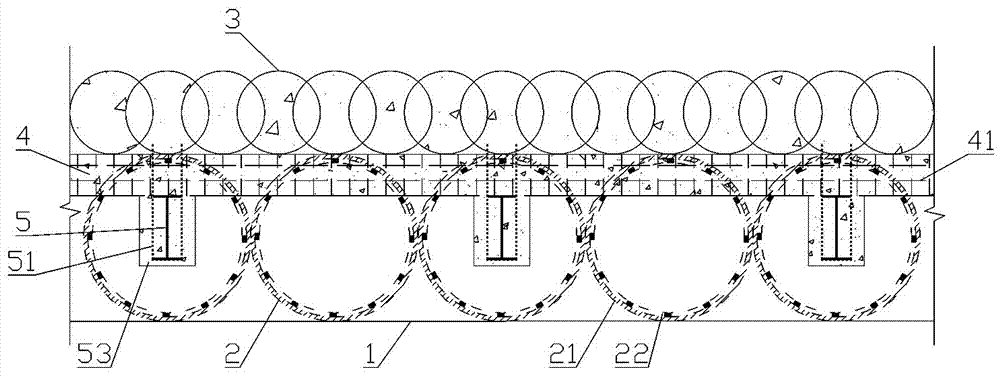

[0040] refer to figure 1 with Figure 10 , a support system for a foundation pit with outer-row and rear-inserted steel double-row piles, which includes a crown beam 1 , support piles 2 , stirring piles 3 , waist beams 4 and support columns 5 arranged in the foundation pit.

[0041] A number of mixing piles 3 are arranged vertically and horizontally along the edge of the foundation pit to form a water-stop curtain, and several supporting piles 2 are arranged vertically and horizontally along the side of the water-stop curtain to form a support body. The cast-in-situ pile structure is composed of a steel casing 21, a steel cage 22 inserted in the steel casing 21, and concrete poured in the steel casing 21. The mixing pile 3 has a section above the supporting pile 2.

[0042] The side of the crown beam 1 is connected to the side of the water-stop curtain, and the bottom is connected to the top of the support body. The crown beam 1 adopts a reinforced concrete structure and is c...

Embodiment 2

[0047] refer to Figure 2 to Figure 10 , the construction method of the outer row and rear insertion type steel type double row pile foundation pit support system of embodiment 1, which comprises the following construction steps.

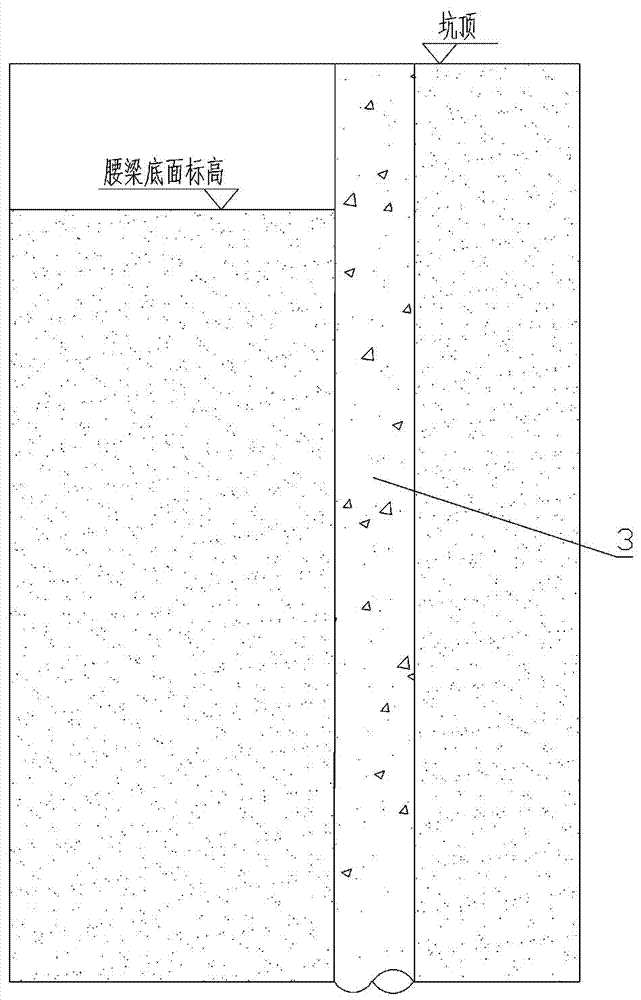

[0048] Step 1, refer to figure 2 According to the conventional technology construction mixing pile 3, after all the mixing piles 3 become piles to form a water-stop curtain, an earthwork excavation is carried out, and the earthwork excavation reaches the elevation position of the bottom surface of the waist beam 4.

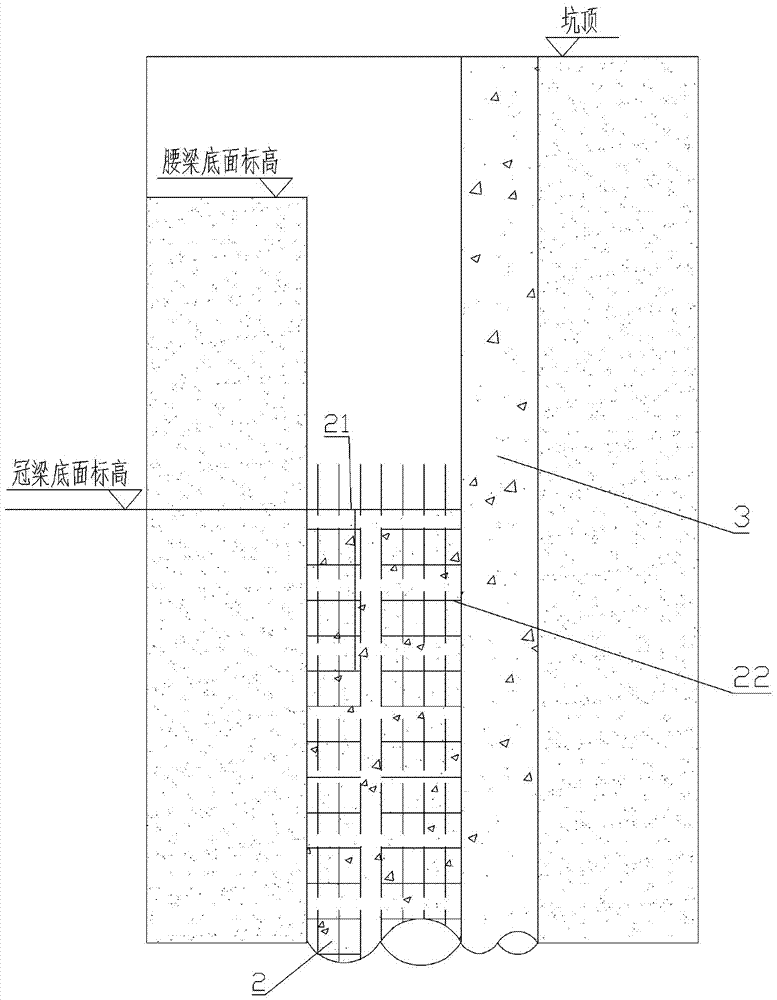

[0049] Step 2, refer to Figure 3 to Figure 6 , construct the support pile 2 and the support column 5 in sequence;

[0050] Step 2.1, refer to image 3 , dig the support pile hole at the side support pile position of the water-stop curtain, sink the steel casing 21 into the support pile hole so that the top is at the elevation of the bottom surface of the crown beam 1, place the steel cage 22 in the steel casing 21 and make it 50 m...

Embodiment 3

[0065] The difference between the construction method of the outer row and rear inserted double-row pile foundation pit support system of this embodiment and the embodiment 2 lies in the specific construction process of the hanging net sprayed concrete layer 6, and the construction of the step 3.3 and step 4.4 is used to replace the embodiment 2 In step 5, complete the hanging net sprayed concrete layer 6 in the foundation pit support system of embodiment 1, specifically:

[0066] Step 3.2 also includes step 3.3 after step 3.2 in step 3 of embodiment 2. The metal hanging net is hung above the waist beam 4 on the side of the mixing pile of the water-stop curtain above the waist beam 4, and the thickness of 100mm to 150mm is formed by spraying concrete on the metal hanging net. Hanging net sprayed concrete layer 6.

[0067] Step 4.3 also includes step 4.4 after step 4.3 in step 4 of embodiment 2. The metal hanging net is hung between the waist beam 4 and the crown beam 1 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com