Secondary grouting method for shield tunnel duct piece

A shield tunnel segment and secondary grouting technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as poor synchronous grouting effect, blockage of grouting pipelines, and influence on normal construction, etc., to prevent Water comes from the tail of the shield, prevents floating, and ensures the effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

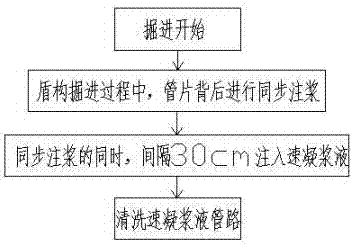

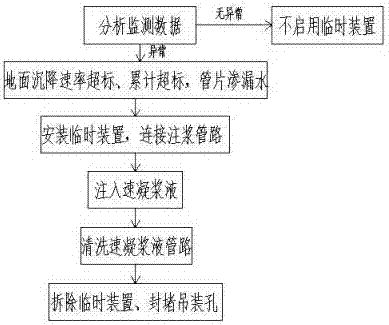

[0024] see figure 1 and figure 2 , in an embodiment of the present invention, a shield tunnel segment secondary grouting method, the steps are as follows:

[0025] Step A: While synchronously injecting the mortar, inject the quick-setting mixed liquid into the grouting liquid filling area through the standby grouting pipeline of the shield machine;

[0026] Step B: While the shield machine is driving or stopping driving, inject the quick-setting mixed liquid to the back of the lining of the segment that has escaped from the 4-5 rings of the shield tail through the device temporarily installed on the segment.

[0027] In the step A, injecting the quick-setting mixed liquid into the grouting liquid filling area adopts the method of interval injection; the interval injection method in the step A includes: grouting once every 30 cm of the shield tunneling;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com