Bulb production device

A light bulb production and equipment technology, applied in the direction of lighting and heating equipment, lighting devices, light sources, etc., can solve the problems of position deviation, accurate alignment, lamp holder crushing, etc., to achieve wide application range, consistent size, avoid wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

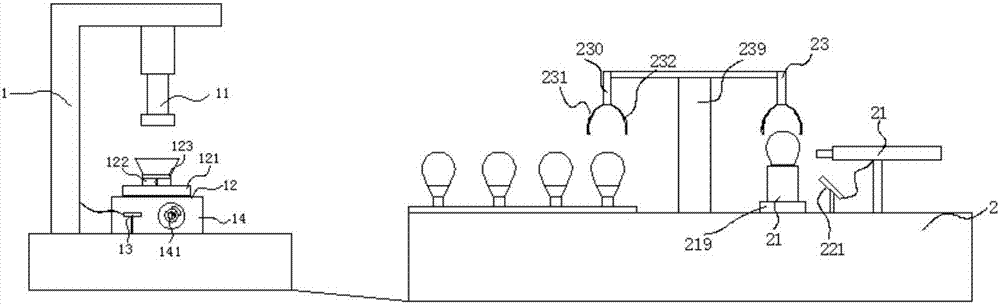

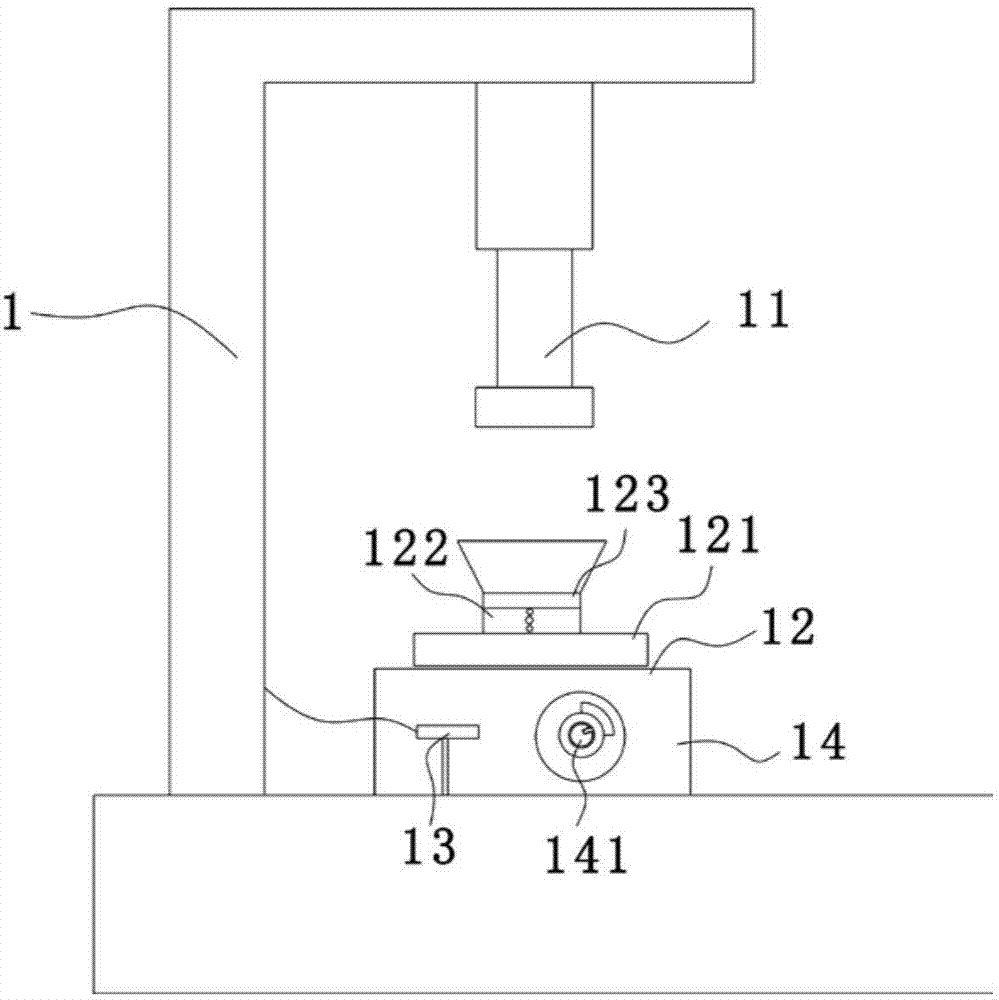

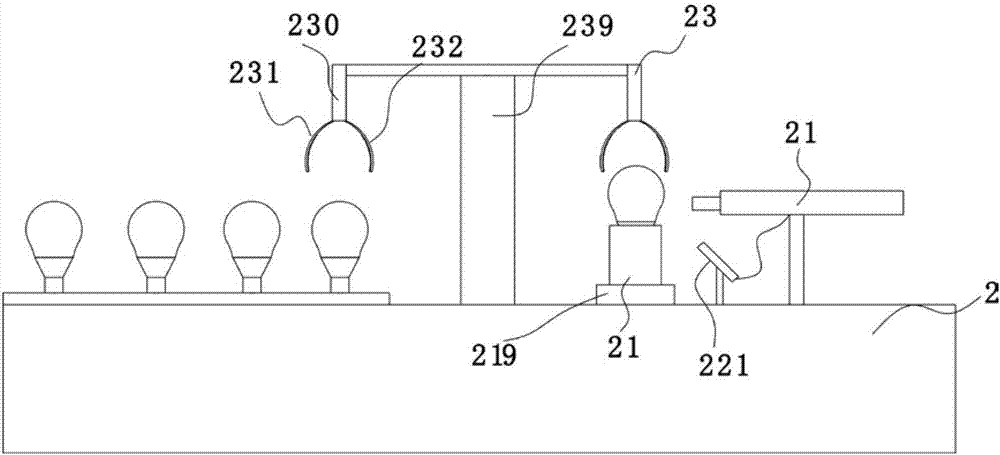

[0027] Such as Figure 1-9As shown, a LED light bulb manufacturing device includes a tablet pressing mechanism 1, a conveying mechanism and a coding mechanism 2, wherein the tablet pressing mechanism 1 includes a pressing device 11, a positioning device 12 and an induction element 13, and the positioning device 12 Including a turntable 121 and a first drive member 14, the first drive member 14 is a motor, the turntable 121 is connected to the first drive member 14 through a rotating shaft, so that the turntable 121 can be driven to rotate when the first drive member 14 starts; 122 is provided in multiples, and is evenly spaced on the turntable; the placing part 122 is a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com