Buried pipeline deformation degree detection method and buried pipeline deformation degree evaluation method

A technology of buried pipelines and deformation degree, which is applied to measurement devices, instruments, optical devices, etc., can solve the problems of large numerical measurement errors of compression deformation, and achieve the effect of accurate control and easy maintenance or replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

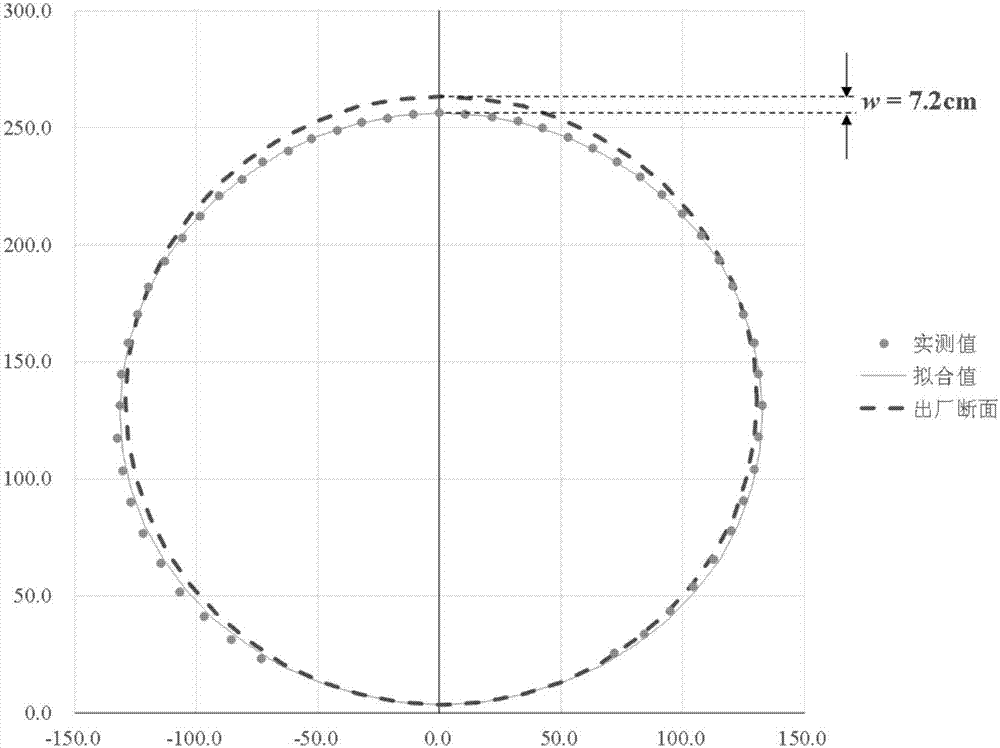

[0042] This embodiment provides a method for detecting the degree of deformation of buried pipelines, including:

[0043] 1. Use a laser section scanner in the lumen of the buried pipeline to collect the coordinates of n detection points located on the inner wall of the buried pipeline. The coordinates of each detection point are:

[0044] where x i is the abscissa of the i-th detection point; z i is the ordinate of the i-th detection point; d i is the distance from the i-th detection point to the rotation center; θ i It is the rotation angle of the i-th detection point with the rotation center as the origin and the horizontal axis set along the horizontal direction; both i and n are positive integers and i is less than or equal to n.

[0045] 2. Bring the coordinates of each detection point into the ellipse standard equation Ax 2 +Bz 2 +Cx+Dz+E=0 to perform data fitting to obtain the first fitting equation. The length of the horizontal axis of the first fitting equat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com