Contact net tension monitoring device

A monitoring device and catenary technology, applied in tension measurement, measuring device, force/torque/work measuring instrument, etc., can solve the problems of inability to monitor the tension change of the catenary system in real time, unable to reflect the real-time dynamic situation of the catenary system, etc. Achieve the effect of improving sand resistance, increasing hardness, and facilitating unified analysis of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in combination with specific embodiments.

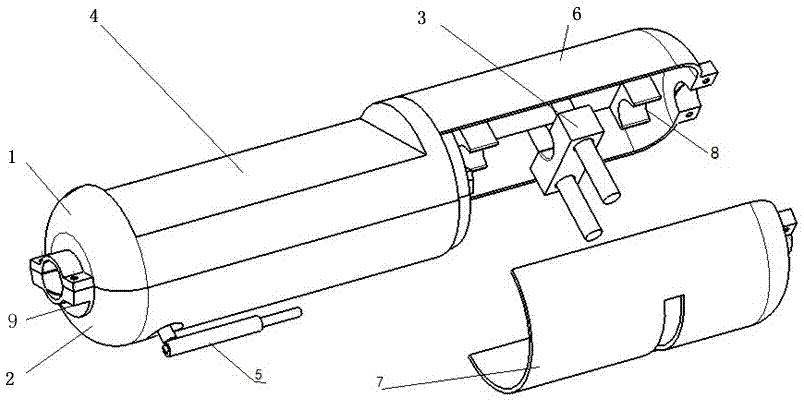

[0029] The invention relates to a catenary tension monitoring device. The device includes a cylindrical shell, and the shell is provided with a through hole in the axial direction, which is the through hole of the catenary wire (including: bearing cable, additional wire, etc.). The aperture can be adaptively adjusted according to the diameters of catenary wires with different specifications. The casing is axially divided into left and right sections. The left section of the housing includes the left upper housing 1 and the left lower housing 2, the two are axially symmetrical up and down butted and fixed by screws; the right section of the housing includes the right upper housing 6 and the right lower housing 7, both axially Butt up and down symmetrically and fix with screws. After being closed, it is a cylindrical structure with good wind resistance. The ends of both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com