Method for simultaneous determination of lactic acid and acetic acid content in liquor fermented grains

A technology of acetic acid content and fermented grains, which is applied in the field of liquor component detection, can solve the problems of unstable peaks, mixed peaks, complex matrix, etc., and achieves the effects of rapid detection, wide detection concentration range and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

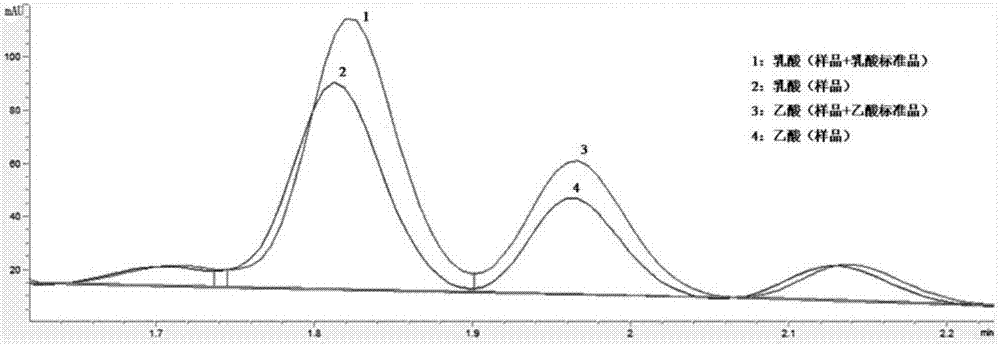

[0041] Example 1 A method for simultaneous determination of lactic acid and acetic acid content in liquor fermented grains

[0042] The steps include diluting the fermented grains sample, extracting the fermented grains sample, centrifuging the extract of the fermented grains, diluting the centrifuged supernatant of the extract of the fermented grains, filtering the diluted liquid and analyzing by liquid chromatography.

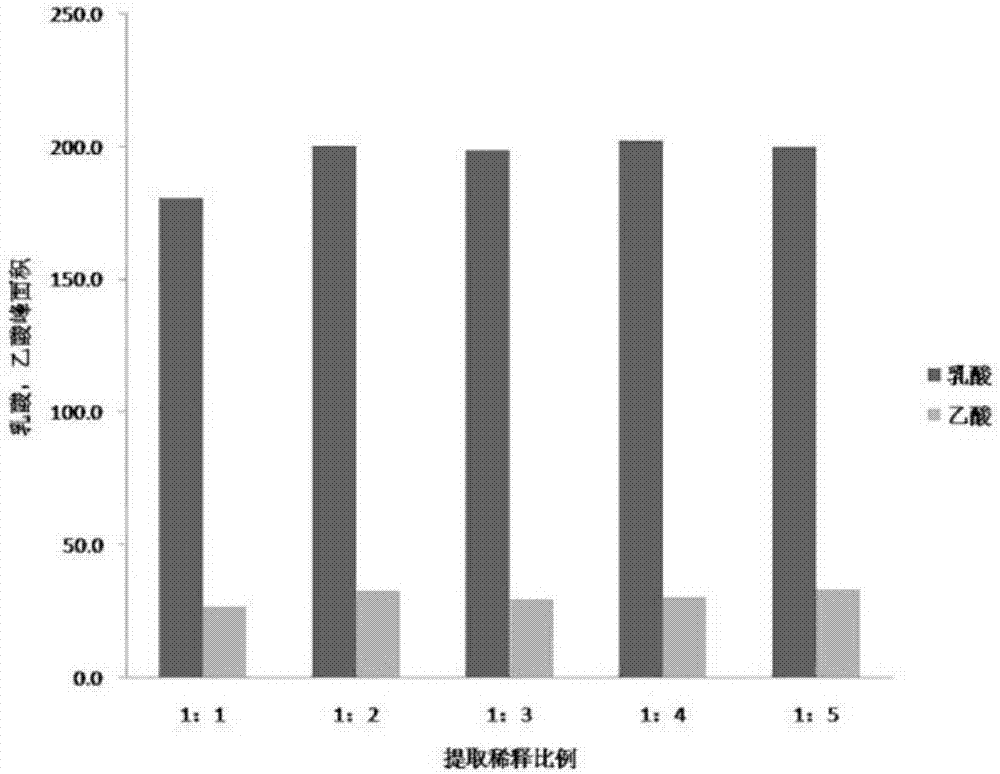

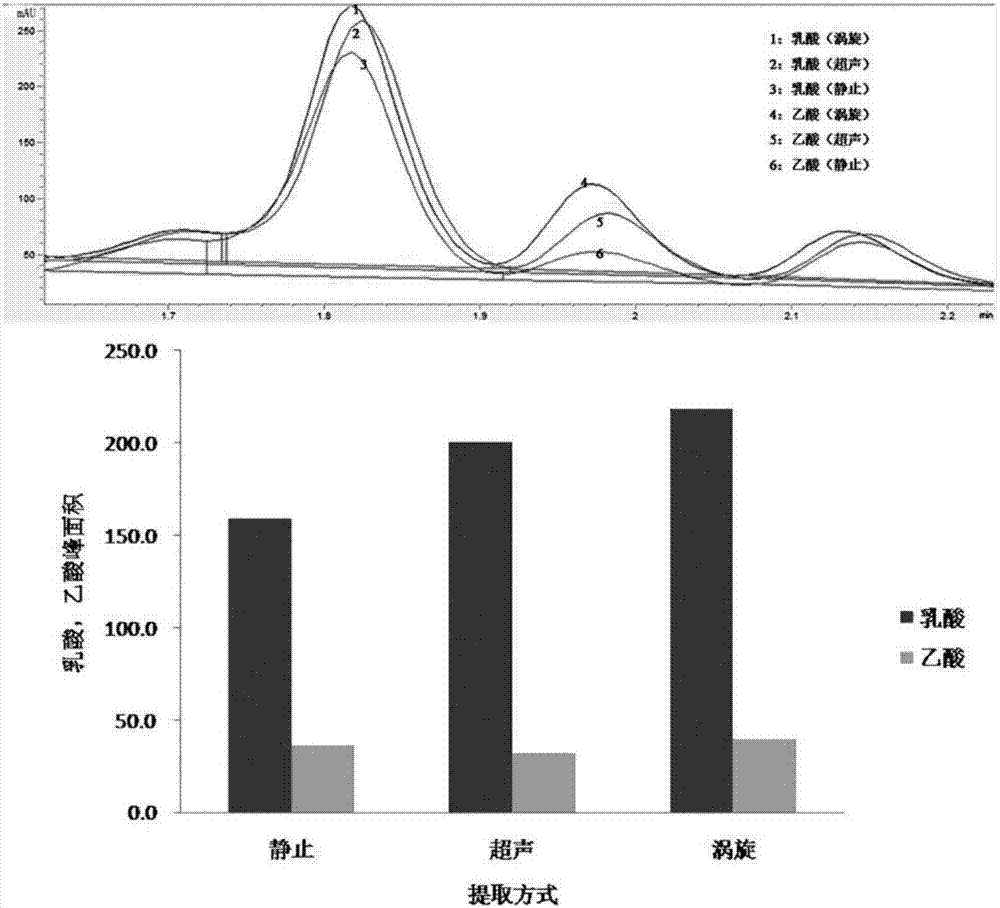

[0043] Specifically, the fermented grains sample was mixed with water at a mass:volume ratio of 1:1, and then vortexed and leached for 10 minutes. After the leaching is finished, centrifuge for 20 min at a temperature of 4° C. and a rotational speed of 11,000 rpm. After centrifugation, take the supernatant after centrifugation and mix it with ultrapure water at a volume ratio of 1:30. Finally, liquid chromatography analysis was carried out.

[0044] The conditions of the liquid chromatography analysis step are as follows: the chromatographic column adopts t...

Embodiment 2

[0048] Example 2 A method for simultaneous determination of lactic acid and acetic acid content in liquor fermented grains

[0049]The steps include diluting the fermented grains sample, extracting the fermented grains sample, centrifuging the extract of the fermented grains, diluting the centrifuged supernatant of the extract of the fermented grains, filtering the diluted liquid and analyzing by liquid chromatography.

[0050] Specifically, the fermented grains sample and water were mixed, vortexed and leached for 15 minutes according to the mass:volume ratio of 1:2. After the leaching is completed, centrifuge for 10 min at a temperature of 4° C. and a rotational speed of 12000 rpm. After centrifugation, take the supernatant after centrifugation and mix it with ultrapure water at a volume ratio of 1:30. Finally, liquid chromatography analysis was carried out.

[0051] The conditions of the liquid chromatography analysis step are as follows: the chromatographic column adopts...

Embodiment 3

[0055] Example 3 A method for simultaneous determination of lactic acid and acetic acid content in liquor fermented grains

[0056] The steps include diluting the fermented grains sample, extracting the fermented grains sample, centrifuging the extract of the fermented grains, diluting the centrifuged supernatant of the extract of the fermented grains, filtering the diluted liquid and analyzing by liquid chromatography.

[0057] Specifically, the fermented grains sample and water were mixed and vortexed and extracted for 10 minutes according to the mass:volume ratio of 1:2. After the leaching is completed, centrifuge for 10 min at a temperature of 4° C. and a rotational speed of 13000 rpm. After centrifugation, take the supernatant after centrifugation and mix it with ultrapure water at a volume ratio of 1:30. Finally, liquid chromatography analysis was carried out.

[0058] The conditions of the liquid chromatography analysis step are as follows: the chromatographic column ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com