Array substrate and display panel

An array substrate, electrostatic technology, applied in optics, instruments, electrical components, etc., can solve the problems of no anti-static unit design on the array substrate, lower product yield, damage to the display area, etc., to improve the anti-ESD ability, improve product quality quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

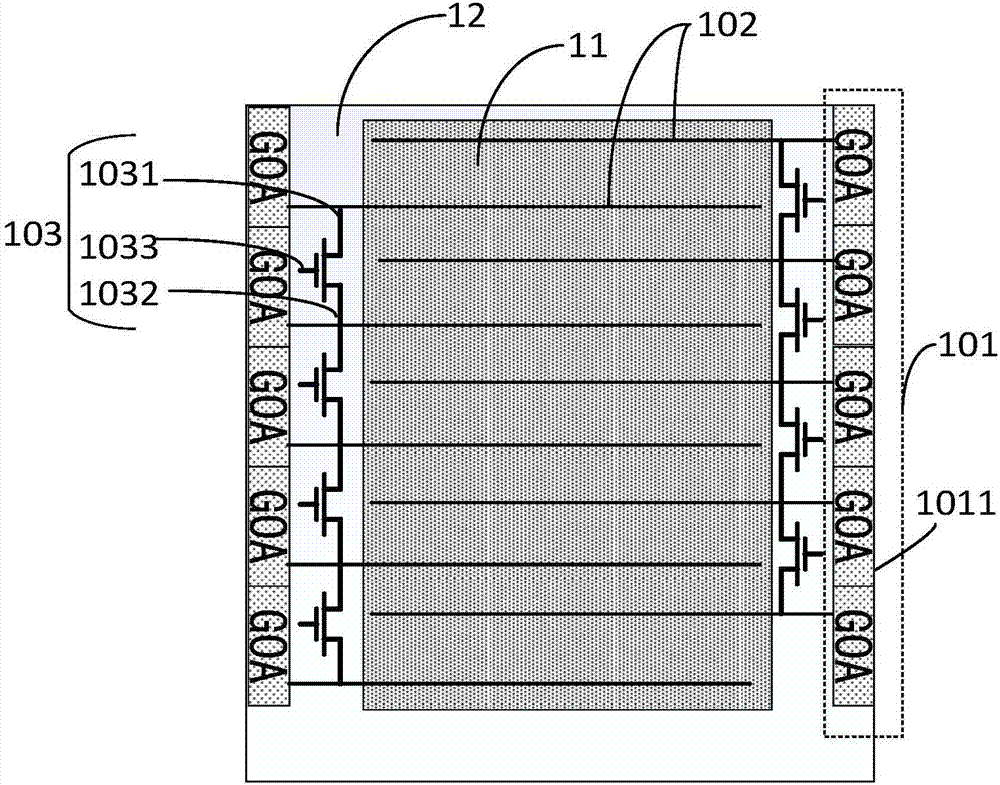

[0025] refer to figure 1 , figure 1 It is a structural schematic diagram of the first embodiment of the array substrate of the present invention.

[0026] like figure 1 As shown, the array substrate is divided into a display area 11 and a non-display area 12 . The array substrate includes a GOA unit 101, a plurality of gate signal lines 102 and an electrostatic conduction device. Further, the GOA unit 101 includes several GOA subunits 1011 , and the gate signal line 102 is electrically connected to the several GOA subunits 1011 one by one. The electrostatic conduction device is electrically connected between the plurality of gate signal lines 102, so that the gate signal lines 102 are electrically connected to each other. It should be noted that, in this embodiment, the GOA units are distributed on both sides of the array substrate. In other embodiments, the GOA units may also be distributed on only one side of the array substrate, which is not limited in the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com