Vacuum pump for conveying steamed stuffed bun stuffing fluids

A vacuum pump and filling technology, which is applied in the fields of food forming, food science, and application, can solve problems such as differences in the taste of buns, uneven fillings, and differences in softness and hardness of bun fillings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

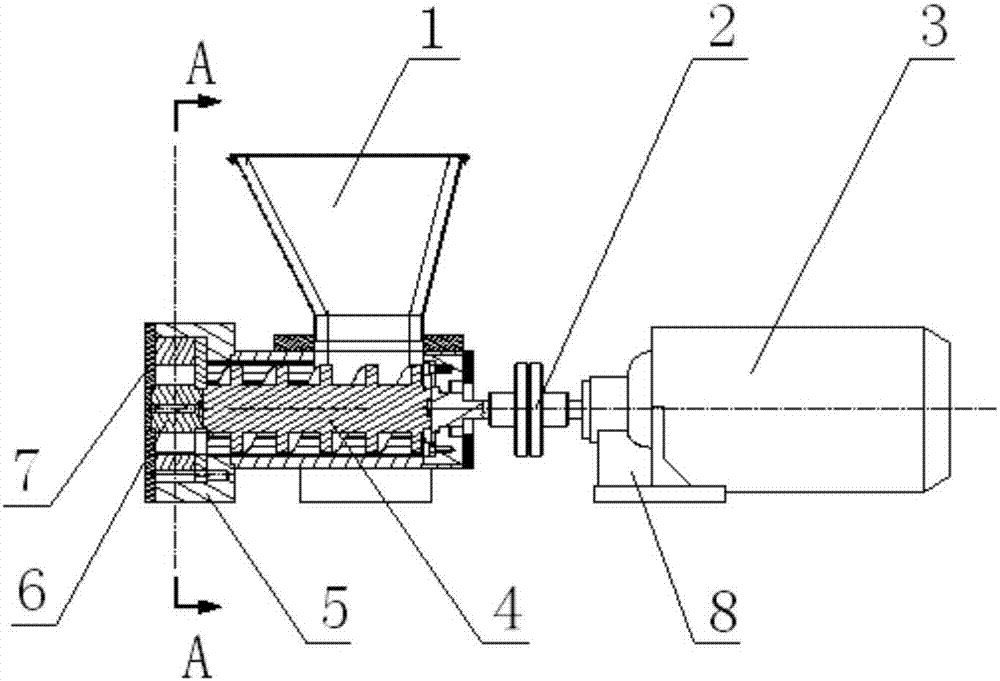

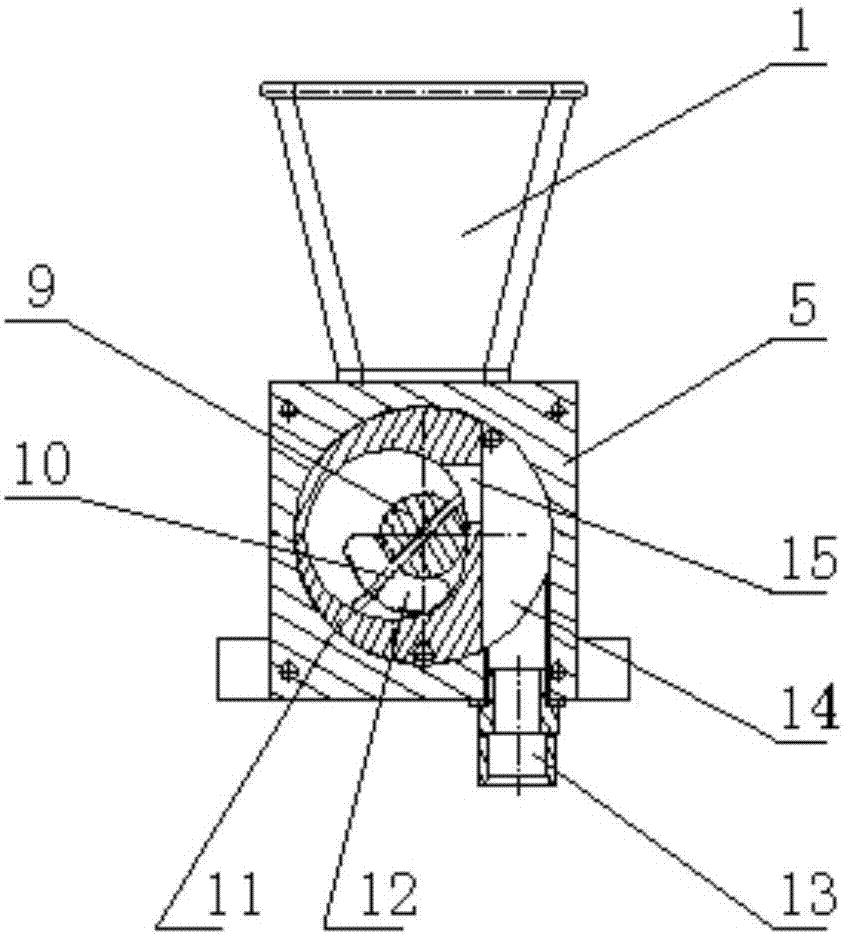

[0012] like figure 1 , figure 2 As shown, the stuffing mechanism of the steamed stuffed bun machine includes a motor 3, a coupling 2, a stuffing bucket 1, an auger 4, a vacuum pump 6 for conveying the fluidity of the steamed stuffed bun filling, and an auger end housing 5. The auger 4 has an auger The main shaft of the dragon and the main shaft of the auger are in a horizontal state. The main shaft of the auger is connected with the motor 3 through the coupling 2. The motor 3 is placed on the motor bracket 8. The main shaft of the auger is located directly under the filling bucket 1. The end of the main shaft of the auger has a stirring The auger end housing 5 and the cover plate 7 have a vacuum pump 6 for transporting fluid in the cavity formed by the auger end housing 5 and the cover plate 7 .

[0013] The vacuum pump 6 for transporting steamed bun stuffing includes a vacuum pump rotating shaft 9, a slide plate 10 and a vacuum pump main body 11. The vacuum pump 6 has a stu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com