A method for improving blade feeding accuracy in tobacco shred production

A precision and blade technology, which is applied in the field of improving blade feeding accuracy in the production of tobacco shreds, can solve the problems of high cumulative feeding accuracy in production, excessive feeding instantaneous accuracy, etc., achieve the improvement of feeding instantaneous accuracy and cumulative accuracy, improve internal quality and follow-up Process satisfaction, effect of ensuring universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with specific embodiments.

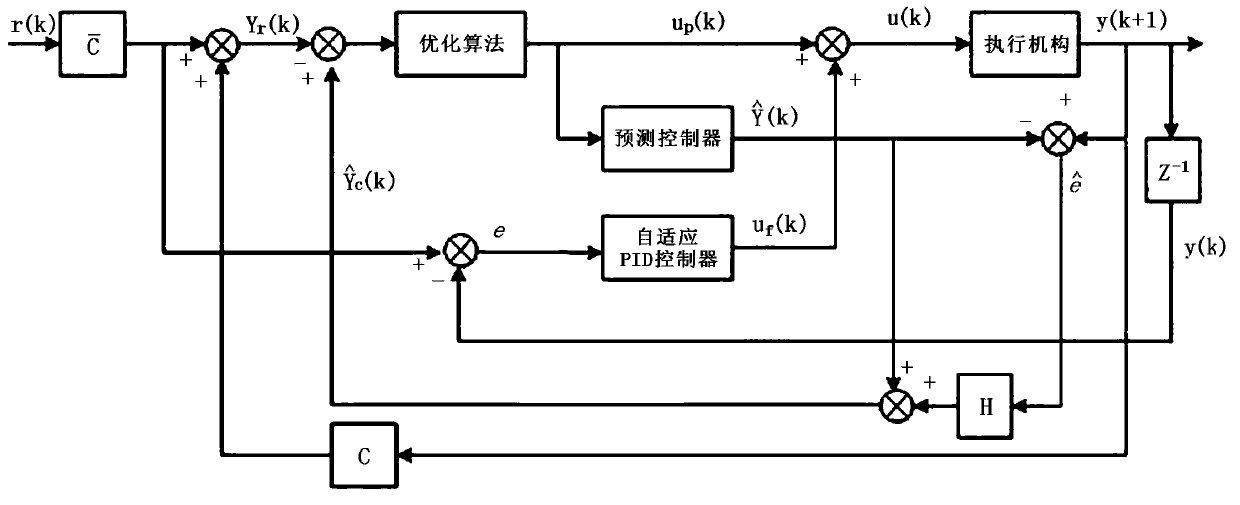

[0061] Such as figure 1 The control system block diagram of the method for improving blade feeding accuracy in tobacco shredded production is shown, and the overall pump frequency output is predicted by the feeding pump frequency u p (k) and feeding pump frequency feedback output u f (k) consists of two parts. u p (k) The calculation process is that the predictive controller calculates the predicted output value of the feeding flow , and the difference between the actual output value y(k) of the feeding flow rate, and corrected by the parameter H, combined with the set value r(k) and y(k) of the feeding flow rate to obtain the reference trajectory Y of the feeding flow rate r (k) Obtain the objective function, and calculate u through the optimization algorithm p (k); u f (k) The error value is obtained from the difference between y(k) and r(k), and is calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com