Electrodeposition Auxiliary Measuring Method for Gap in Micro Electrolytic Wire Cutting

A technology for cutting processing and auxiliary measurement, which is applied in the direction of electric processing equipment, metal processing equipment, measuring/indicating equipment, etc. It can solve the problems of complex distribution of processing gaps and achieve good fluidity, high precision, and high transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

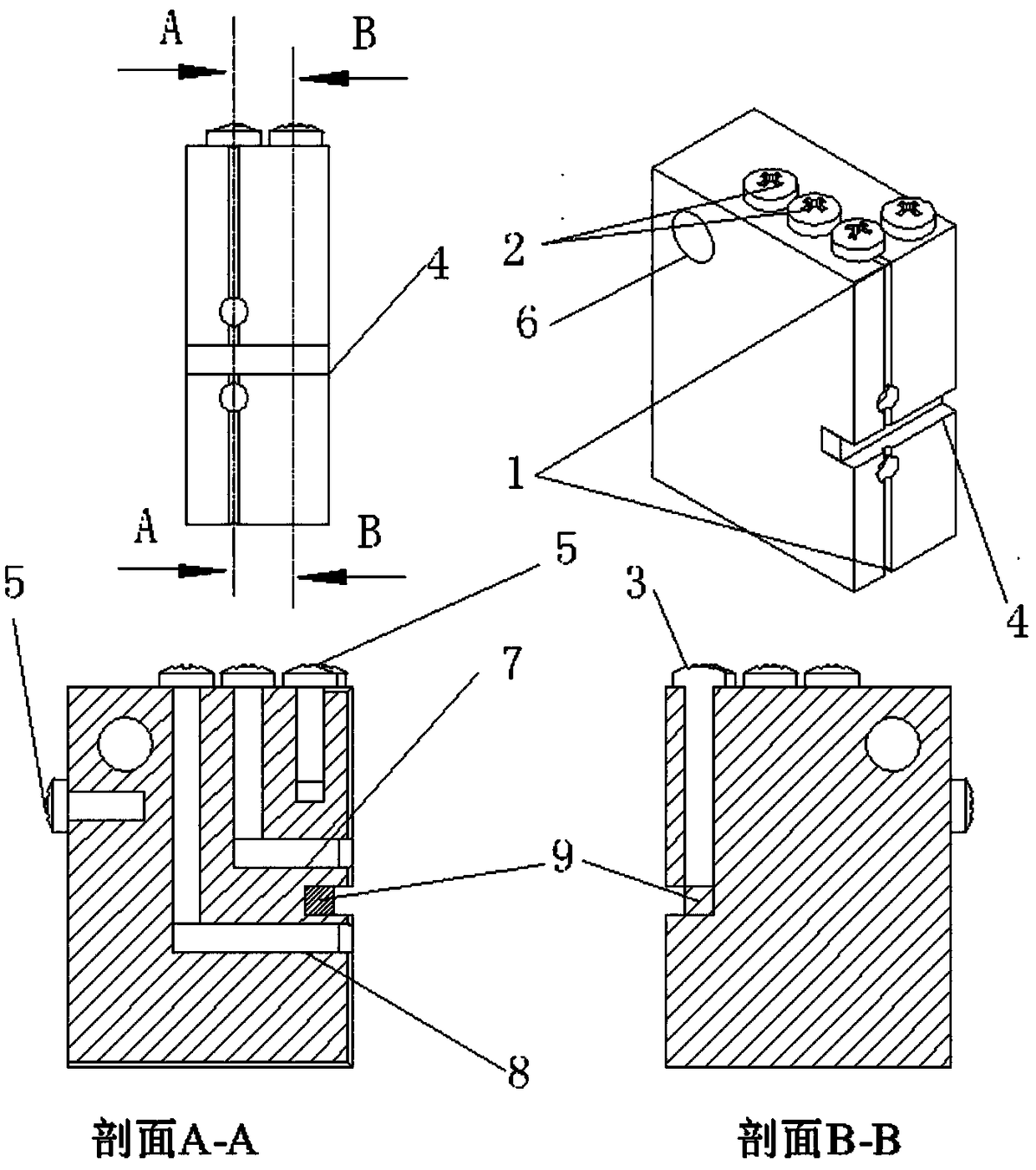

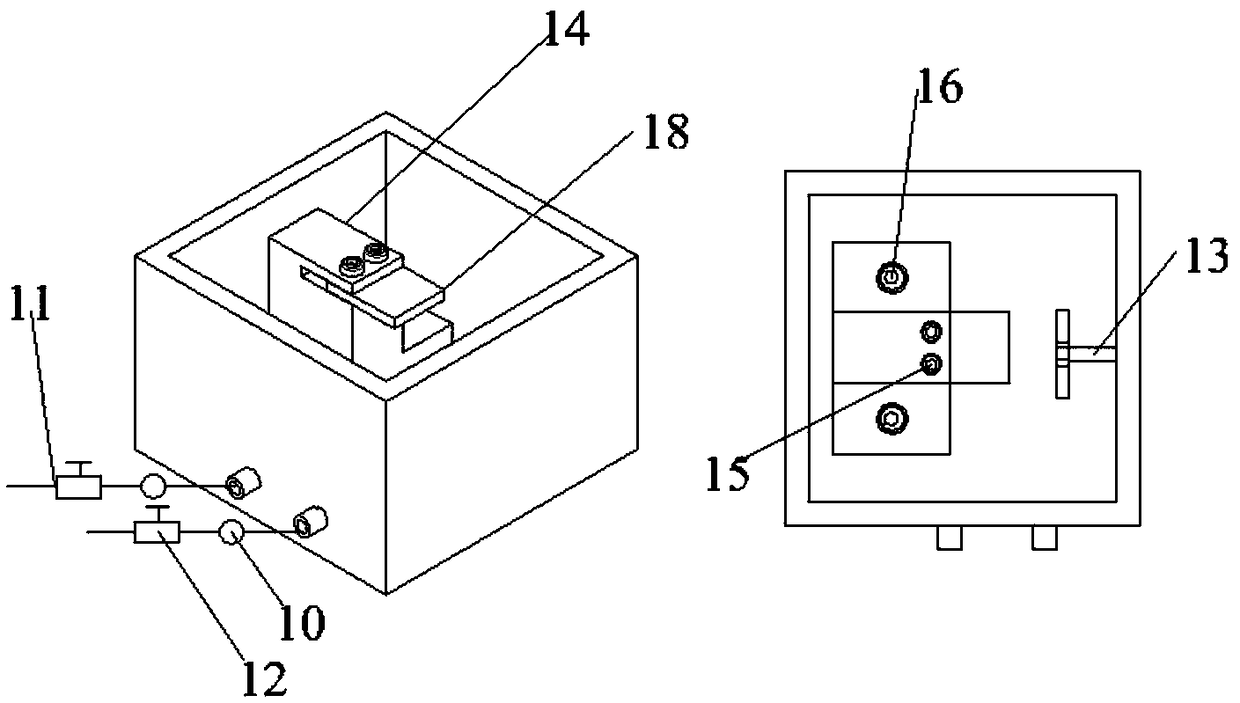

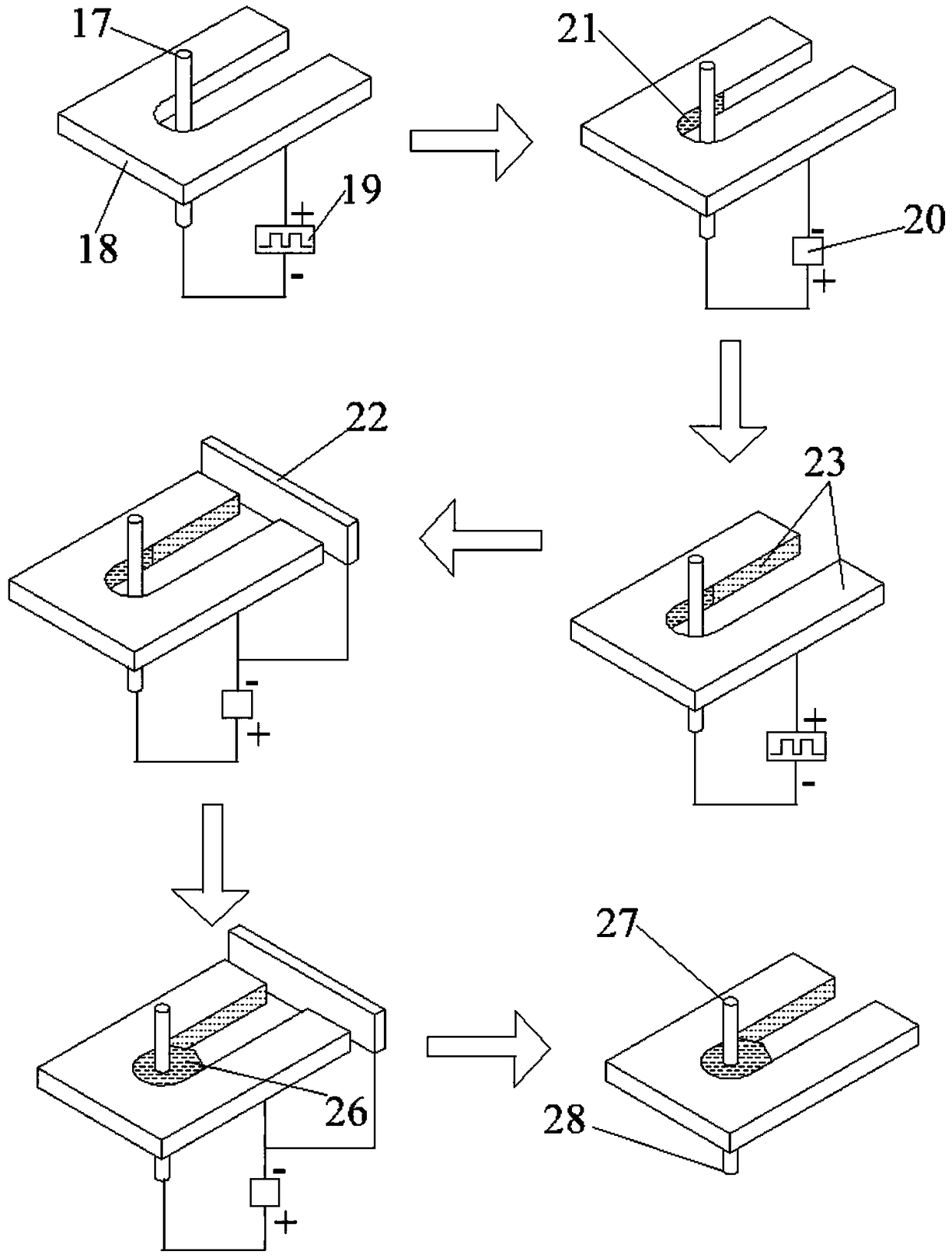

[0033] figure 1 The micro-scale wire electrode installation fixture is installed on the x-y-z three-dimensional precision displacement platform through the wire electrode fixture installation positioning hole 6, wherein the micro-scale wire electrode 10 is installed in the positioning groove 1 of the fixture through the wire electrode fastening screw 5, and the wire The electrode maintains a certain pre-tightening force; the electrodeposition auxiliary electrode 9 is added to the groove 4 behind the micro-slit cutting area, and the polarity of the auxiliary electrode is controlled by the deposition auxiliary electrode lead screw 3 to control the polarity of the auxiliary electrode; when the wire electrode passes through the fastening screw 5 is connected to the anode of the power supply, the upper part of the wire electrode melts off the cathode 7 and the lower part of the cathode 8 melts off the cathode. When the lead screw 2 is connected to the pulse power supply cathode thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com